Novel method for manufacturing dual-purpose berth and writing desk combination structure

A manufacturing method and technology of a writing desk, applied in applications, home appliances, furniture parts, etc., can solve problems such as airtightness and large quality fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

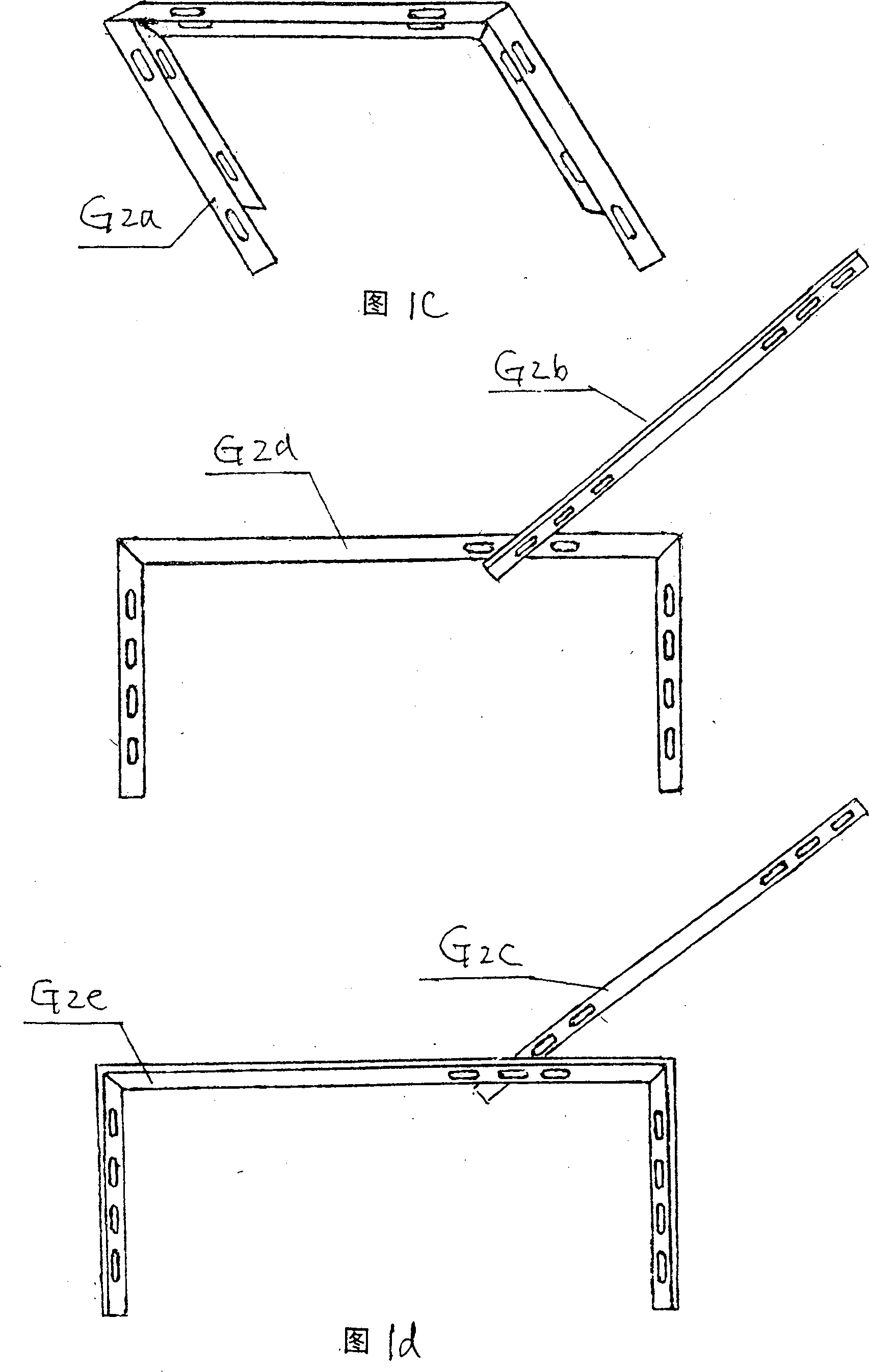

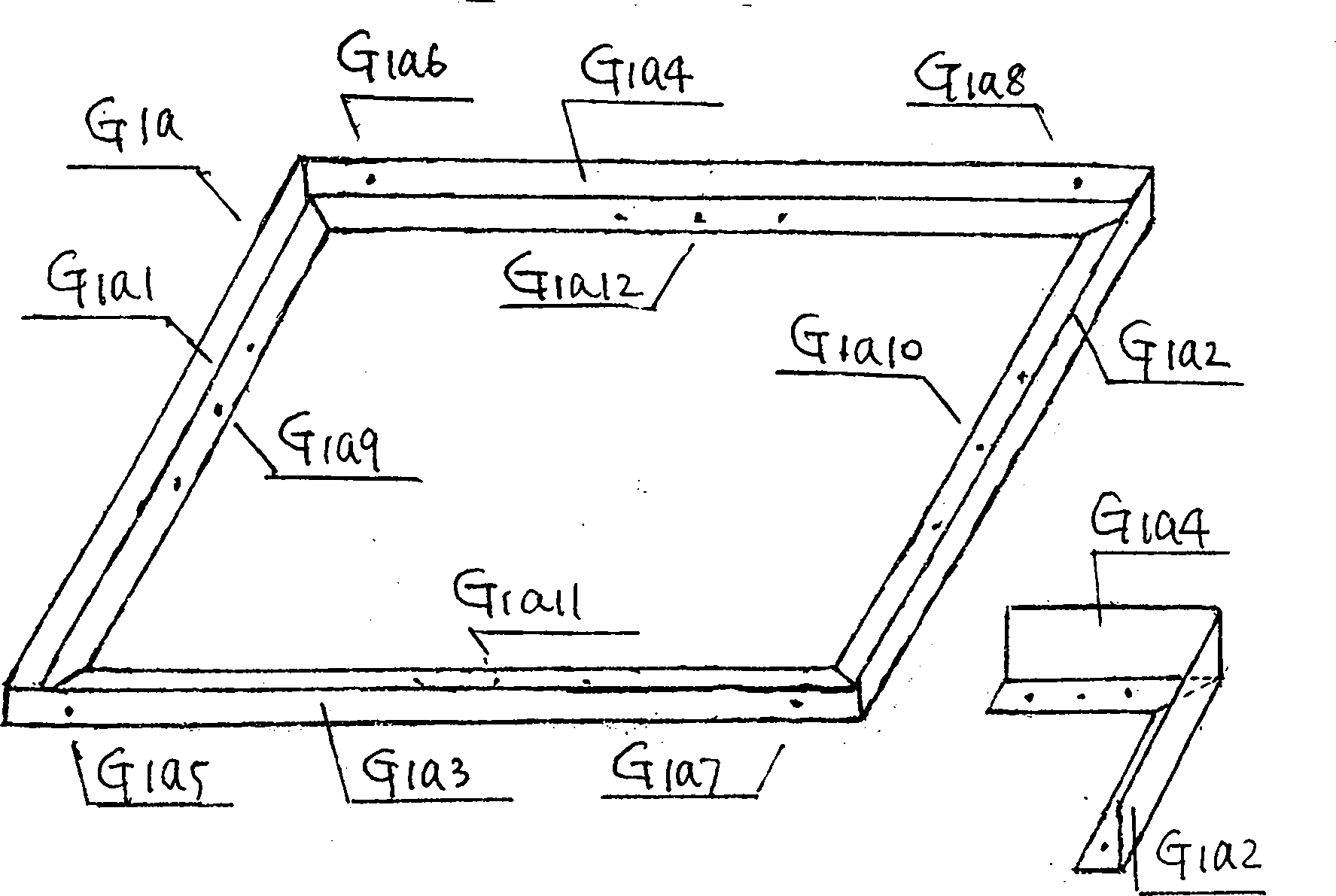

[0012] Manufacturing method of bed and desk dual-purpose frame G 1. Making angle steel bedstead G1: a. Casting angle steel support frame G1a, the length of the support frame is equal to the length of the bed, the width of the support frame is equal to the width of the bed, and the cross-sectional area of the angle steel It is 6mm by 6mm, and the thickness is 1.5mm. Drill rope holes G1a11, G1a12 at the bottom of the long side G1a3, G1a4 of the support frame, numbered 1a...Na, and drill bolt installation holes G1a5, G1a6 at both ends perpendicular to the bottom edge, G1a7, G1a8, drill rope holes G1a9, G1a10 at the bottom of the short sides G1a1, G1a2 of the support frame, numbered 1b...Tb; b. Make rope plates G1b1, G1b2 with adjustable rope elastic bolts, and the length of a piece is slightly smaller than the angle steel support frame On a thick iron plate whose length and width are half the width of the angle steel, evenly drill several threaded mounting holes to get the rope ...

Embodiment 2

[0014] The production method of bed and desk dual-purpose frame K 1. Make channel steel bedstead K1: a, cast channel steel support frame K1a, the length of K1a short side K1a1, K1a2 is equal to the width of the bed, and the length of long side K1a3, K1a4 is equal to The length of the bed; b. Bolt installation holes K1a5, K1a6, K1a7, K1a8 are drilled at the bottom of the grooves at both ends of the long side K1a3 and K1a4 of K1a, and the rope holes K1a11 and K1a12 are drilled on the bottom side, and the numbers are 1a...1x, on the short side of K1a K1a1, K1a2 are pierced with rope holes K1a9, K1a10 at the bottom, and their numbers are 1b...1y; c. Take a long plastic rope K1b1, tie a knot at one end, and pass through the rope holes K1a11 and K1a12 at the other end, and the crossing number is 1b Bottom thread, 2b top thread, 3b bottom thread, 4b top thread... and so on, until all the rope holes are threaded, and the remaining rope end is hung on the last hole of the rope holes K1a...

Embodiment 3

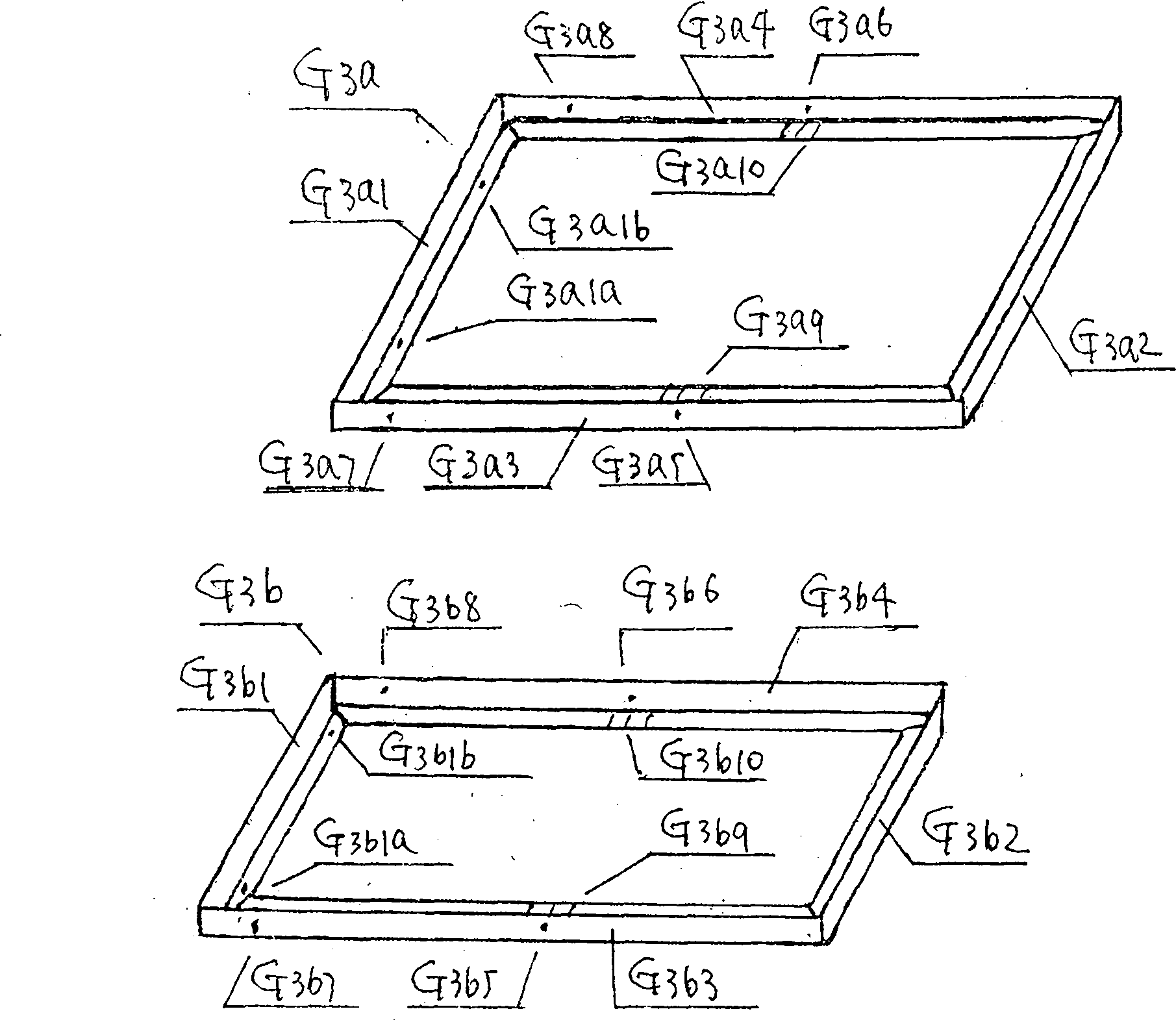

[0016] The production method of the bed and desk dual-purpose frame L 1. Making the bedstead L1: a cut the material used to make the square tube angle iron support frame L1a, the length of the square tubes L1a1 and L1a2 is equal to the width of the bed, and the square tubes L1a3 and L1a4 The length is equal to the length of the bed minus twice the width of the square tube, the length of punched porous angle irons L1a3a and L1a4a on both sides is equal to the length of L1a3 and L1a4, the length of L1a1a and L1a2a is equal to the length of L1a1 minus twice the width of the square tube; b. Weld the angle iron support frame L1ain, arrange L1a3a, L1a4a, L1a1a, L1a2a in a rectangular shape in the ground cement mold groove and weld to obtain L1ain, which has the same shape as G1a; c. Add welded square tube support on the periphery of the angle iron support frame L1ain Frame L1aout, L1a3, L1a4 and L1a3a, L1a4a are aligned tightly, welded on both sides, L1a1, L1a2 and L1a1a, L1a2a, L1a3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com