Sewage filter plant

A filter device and sewage technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of clogged filters, energy loss, complex structure, etc., to avoid accumulation of dirt, simple structure, Effects that are handled in a simple way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

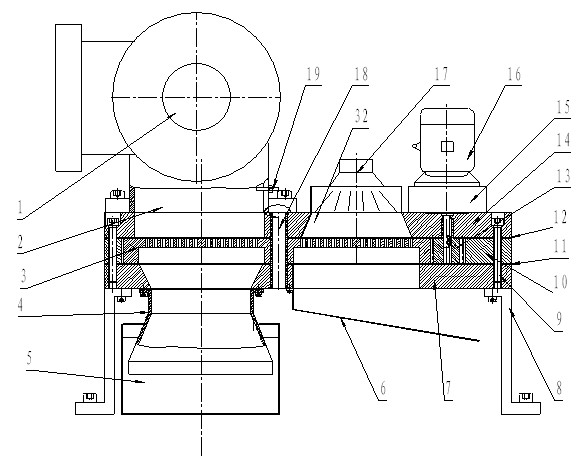

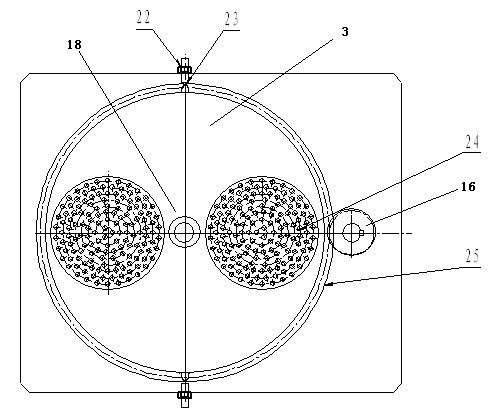

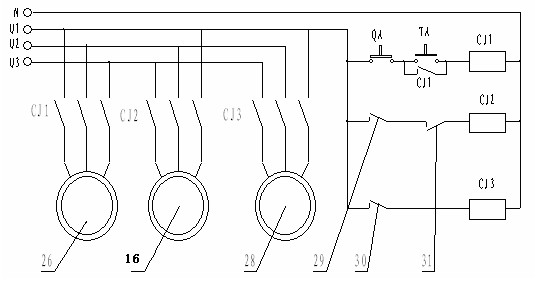

[0021] The sewage filtering device of the present invention comprises a support 8, a water inlet 4, a turntable 3, a rotating shaft 18, a water flushing sprinkler 17, a drive motor 16 and a reducer 15; the support 8 is provided with an upper support plate 14 and a lower support plate 7 , the rotating disk 3 is horizontally arranged between the upper supporting plate 14 and the lower supporting plate 7, the rotating shaft 18 passes through the axis of the rotating disk 3, and the upper and lower ends of the rotating shaft 18 are respectively arranged on the upper supporting plate 14 and the lower supporting plate 7; 2 corresponds to the water inlet 4 up and down, and is arranged on the upper support plate 14 and the lower support plate 7 respectively. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com