Novel screen plate with composite structure

A composite material and a new type of technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of poor load resistance, low overall strength, easy expansion and deformation, etc., to achieve strong noise reduction ability, material saving, self-weight Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

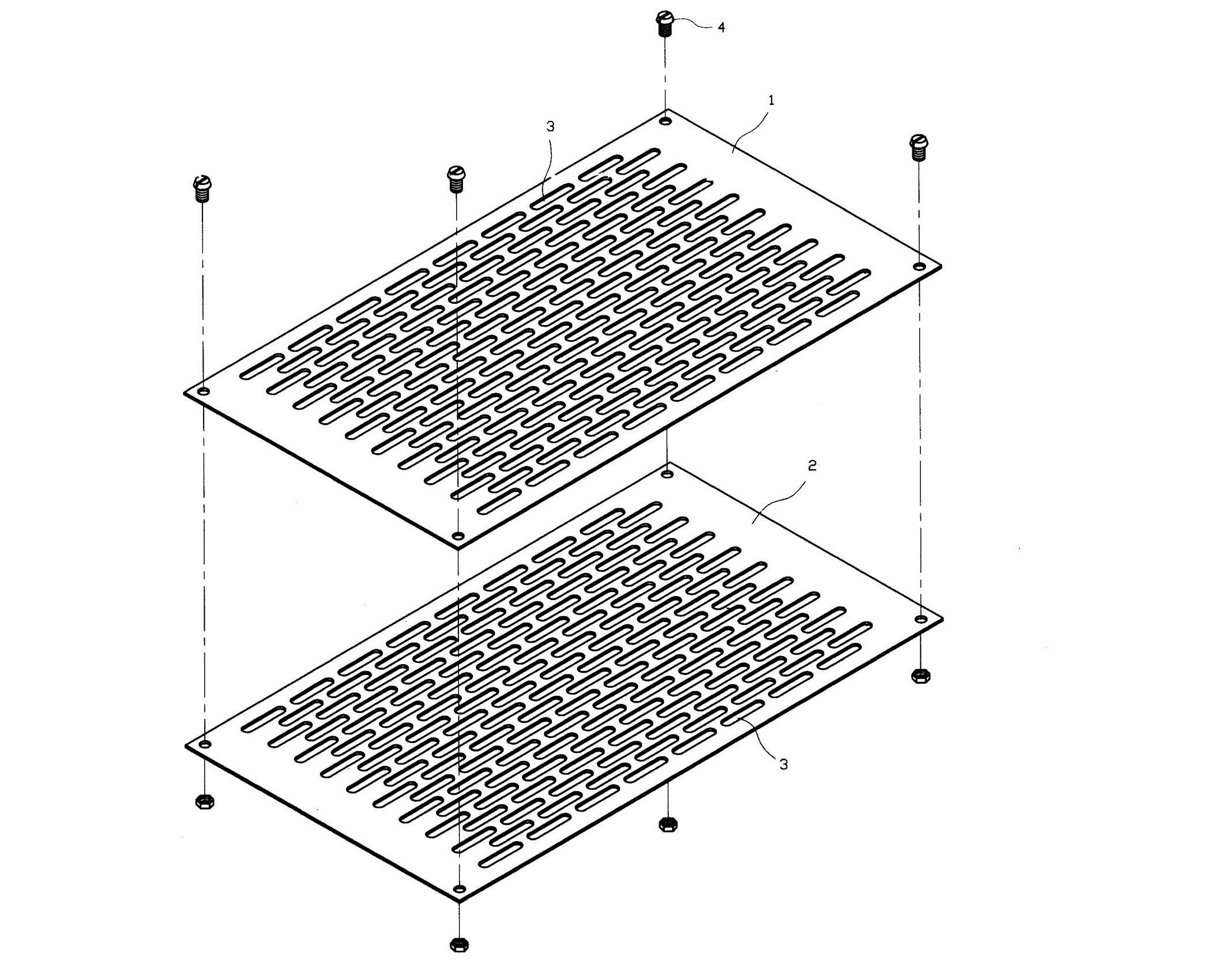

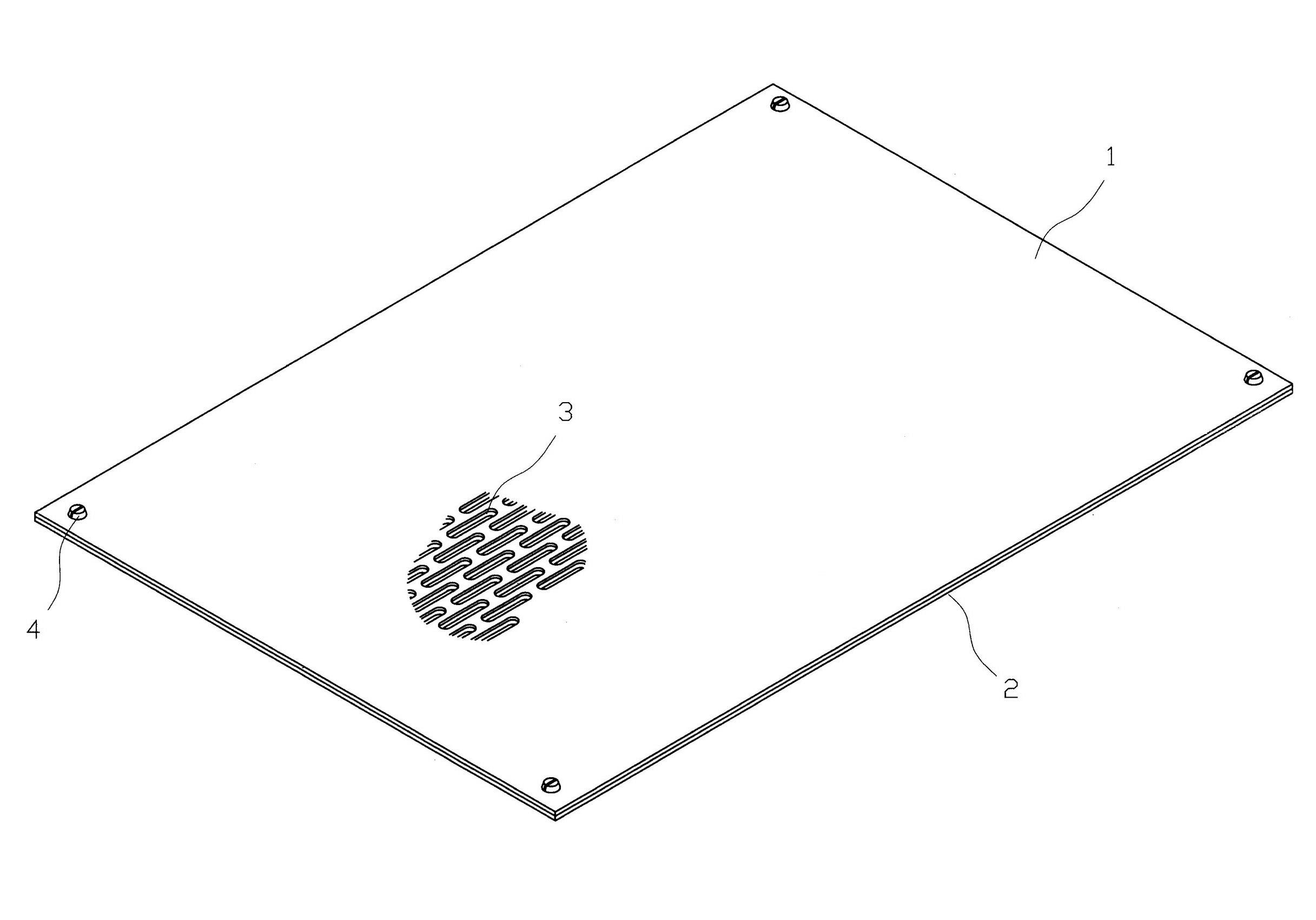

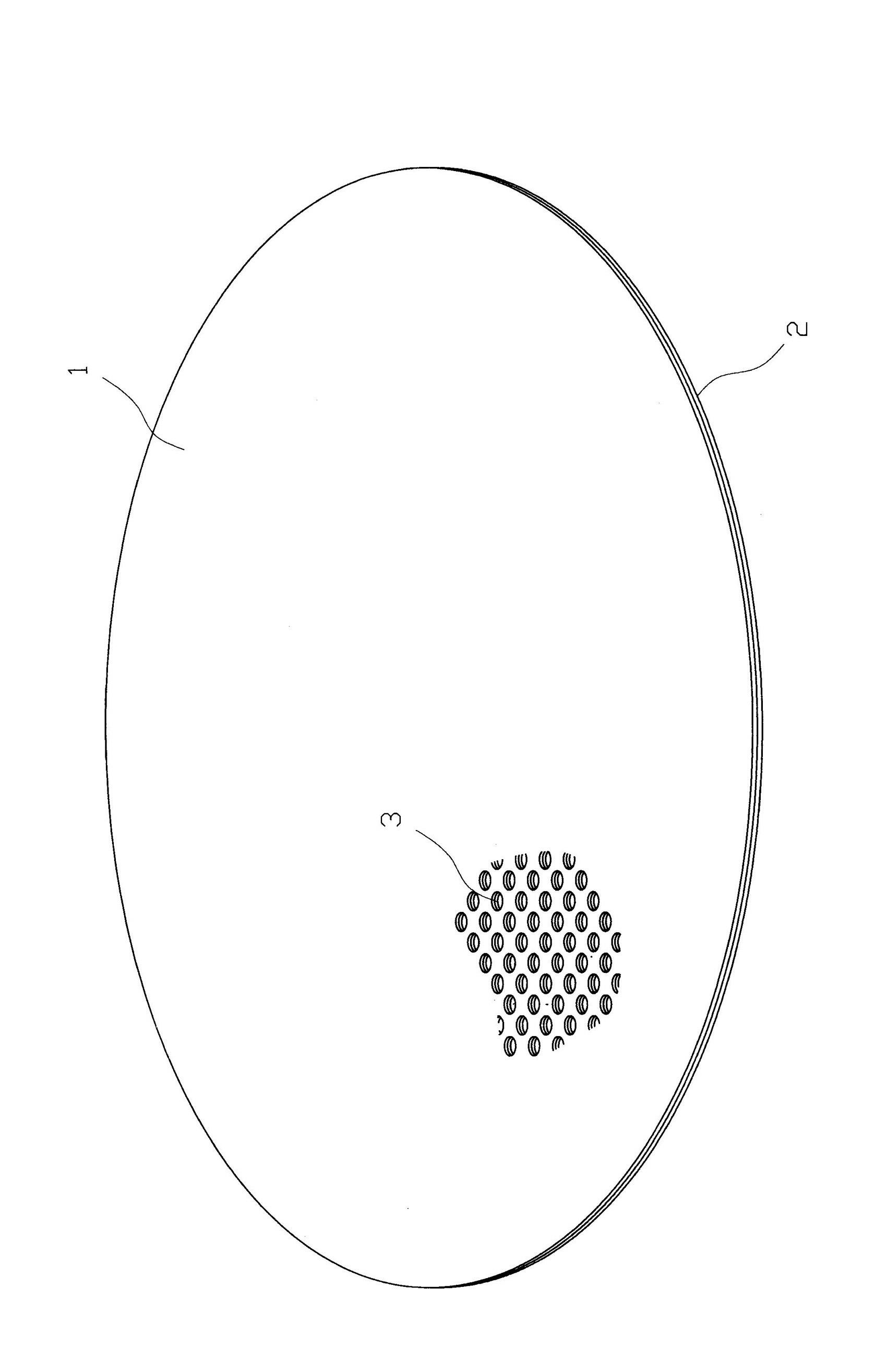

[0012] Depend on Figures 1 to 3 It can be seen that the present invention is fixed as a whole by the sieve surface 1 of compound material and the sieve bottom 2 of metal material, wherein the sieve surface 1 of compound material is arranged on the top, the sieve bottom 2 of metal material is arranged below, and the sieve surface 1 of compound material Corresponding sieve holes 3 are arranged on the sieve bottom 2 made of metal.

[0013] According to the present invention, the screen surface 1 made of compound material and the screen bottom 2 made of metal material are fixed into one body by fasteners 4 , or are glued into one body, or riveted into one body. The sieve surface 1 made of compound material and the sieve bottom 2 made of metal can be designed as a square, or a circle, or a polygon. The sieve surface 1 made of compound material and the sieve hole 3 on the sieve bottom 2 made of metal material can be designed as elongated holes, or square holes, or round holes, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com