Automatic cleaning device for exhaust duct and gluing and developing cabinet

An exhaust duct, automatic cleaning technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, photoengraving process coating equipment, etc. Manpower, the effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

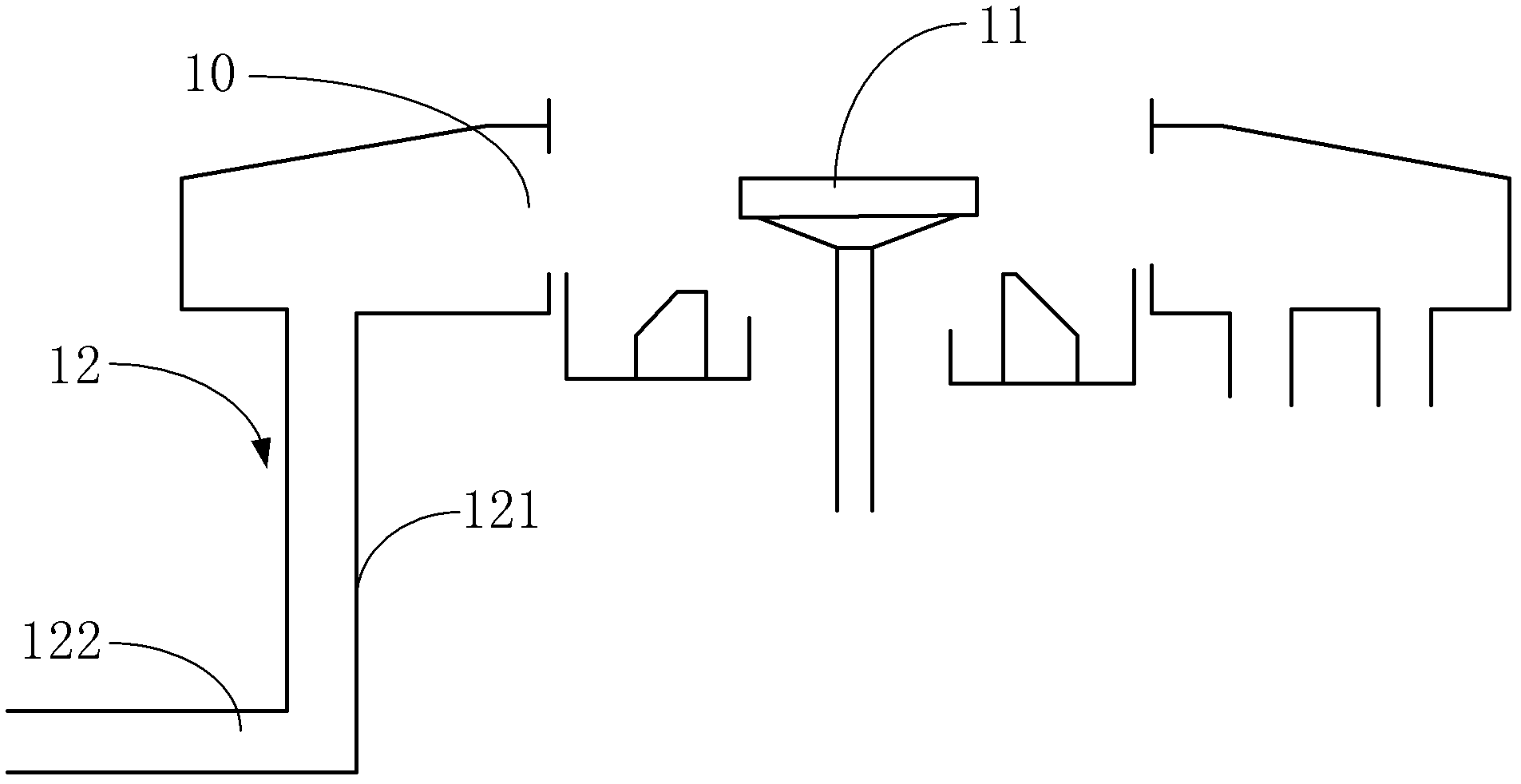

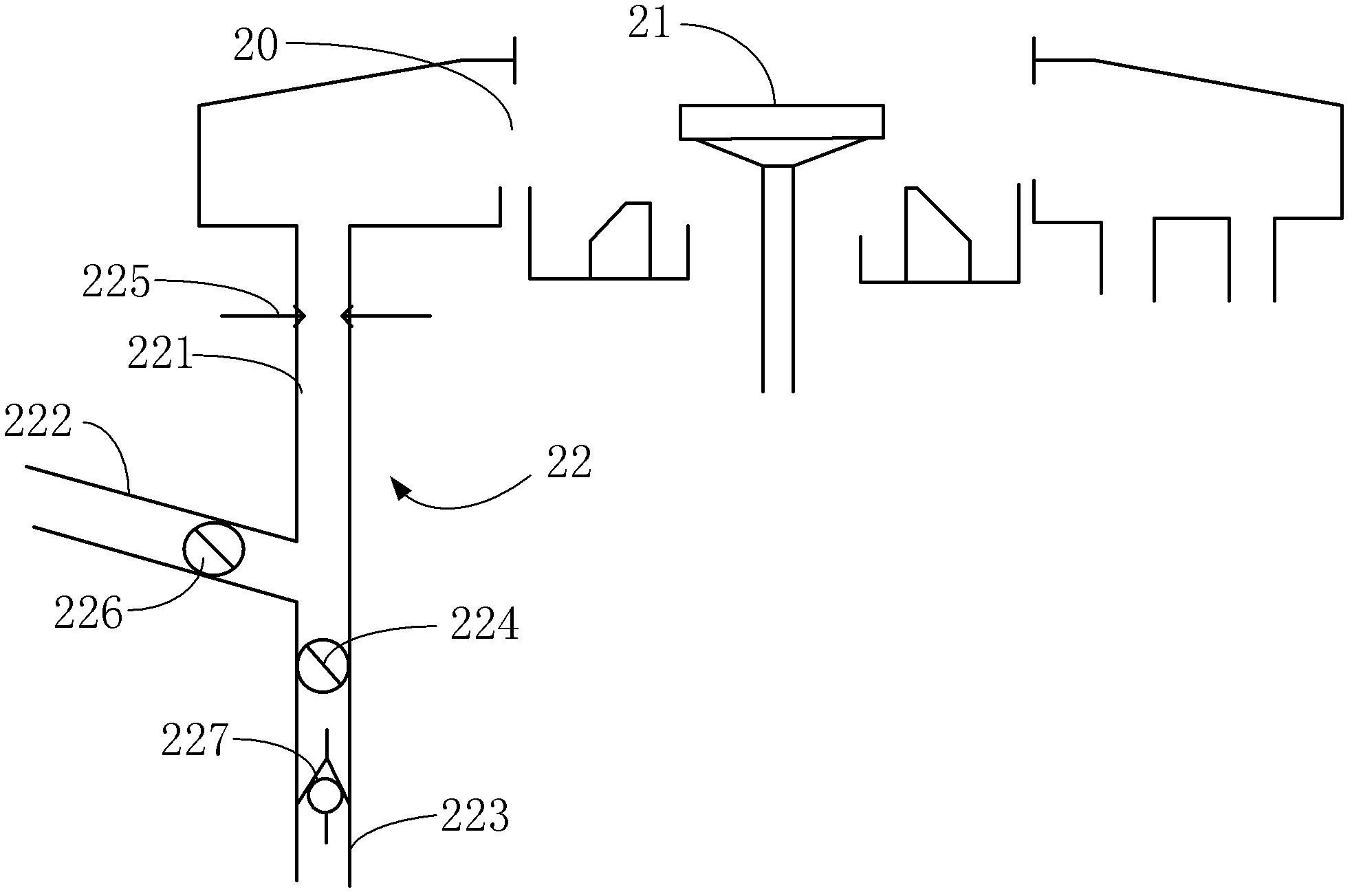

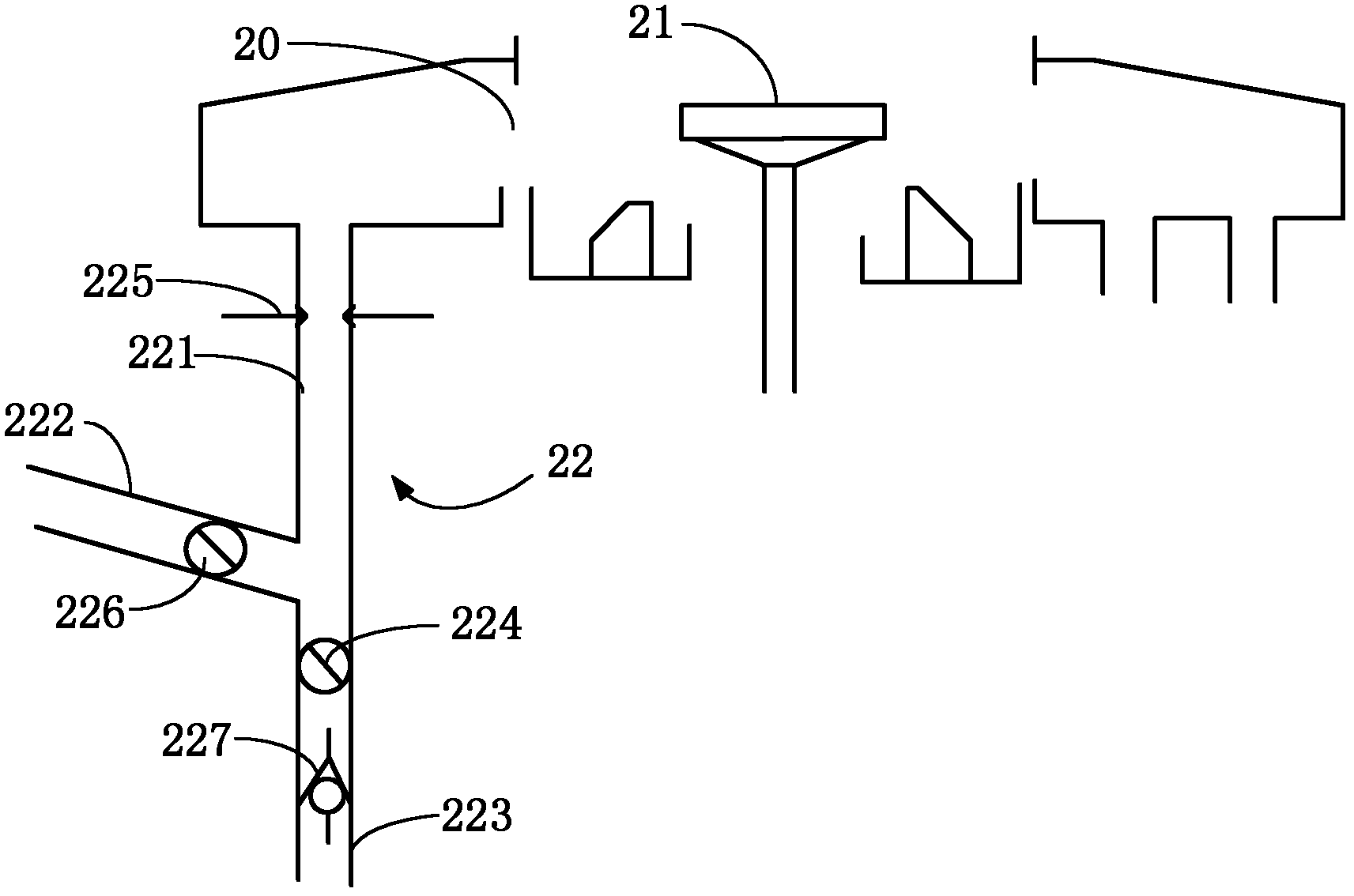

[0019] see figure 2 , figure 2 Shown is a schematic structural view of the exhaust pipe automatic cleaning device and the gumming and developing machine of the present invention. Depend on figure 2 It can be seen that the gluing and developing machine platform provided in this embodiment includes a gluing chamber 20, a wafer carrier 21, an exhaust duct 22, and an exhaust duct automatic cleaning device arranged on the exhaust duct 22. The wafer carrier table 21 is located at the central position of the gluing chamber 20, the wafer is placed on the wafer carrier table 21, the exhaust pipe 22 is arranged at the bottom of the gluing chamber 20, and It communicates with the gluing chamber 20 .

[0020] read on figure 2 , the automa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com