Mould for multi-blank equal-channel angular welding extruded molded pipe

A technology of equal channel corners and extrusion forming, applied in metal extrusion dies, containers of metal to be extruded, metal extrusion, etc., can solve the problems of increasing processing procedures, increasing energy consumption, etc., and reducing extrusion force , The product has the effect of small grain size and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

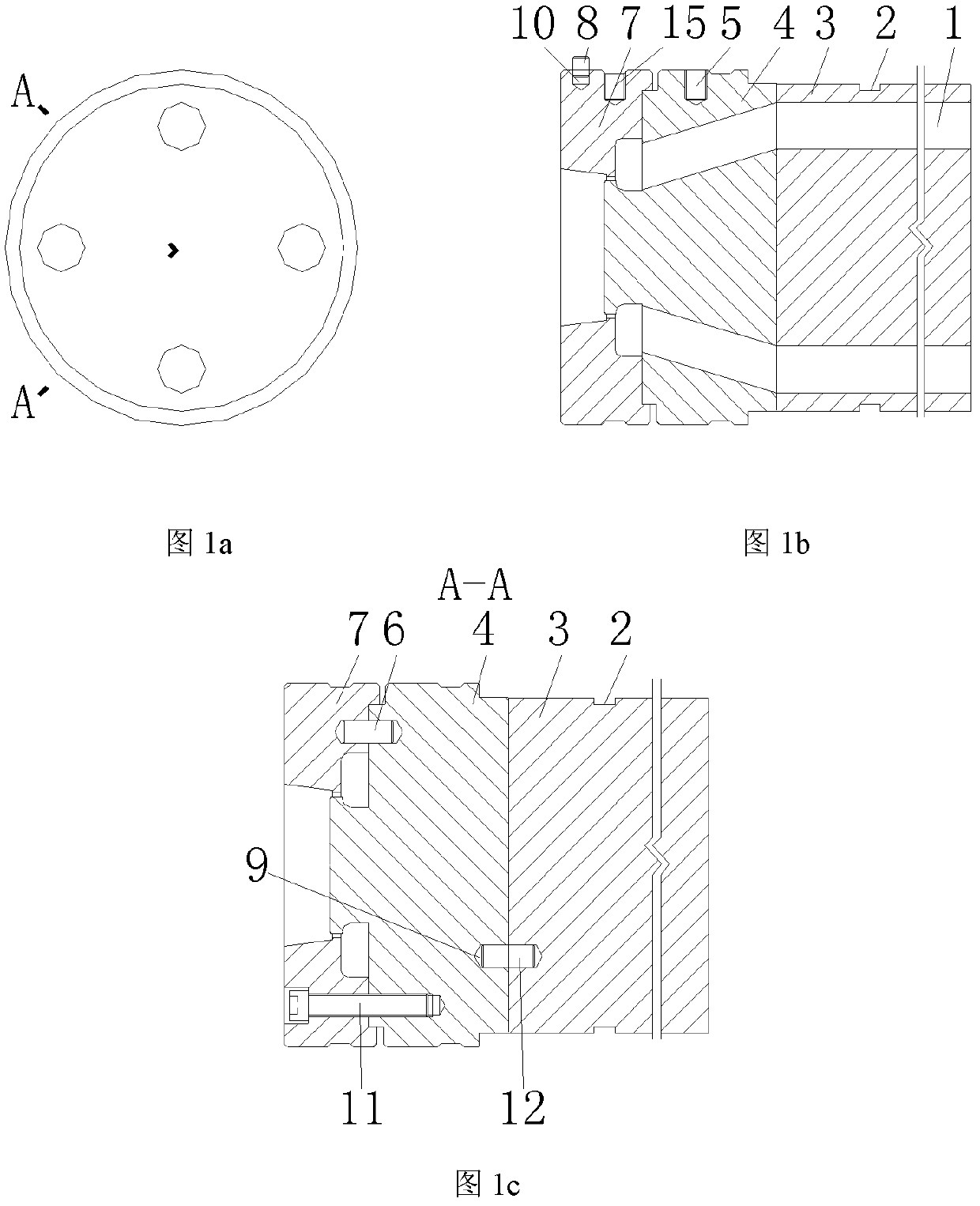

[0025] This embodiment is a die for forming a fine-grained alloy tube by multi-blanket equal channel corner welding and extrusion, which is used for extruding and forming a fine-grained magnesium alloy tube. The diameter of the extruded pipe product is a round pipe with a thickness of 104mm and a thickness of 3mm. The tonnage of the extruder used in the forming process is 2500t. Use H13 hot work die steel to make die and other extrusion tools.

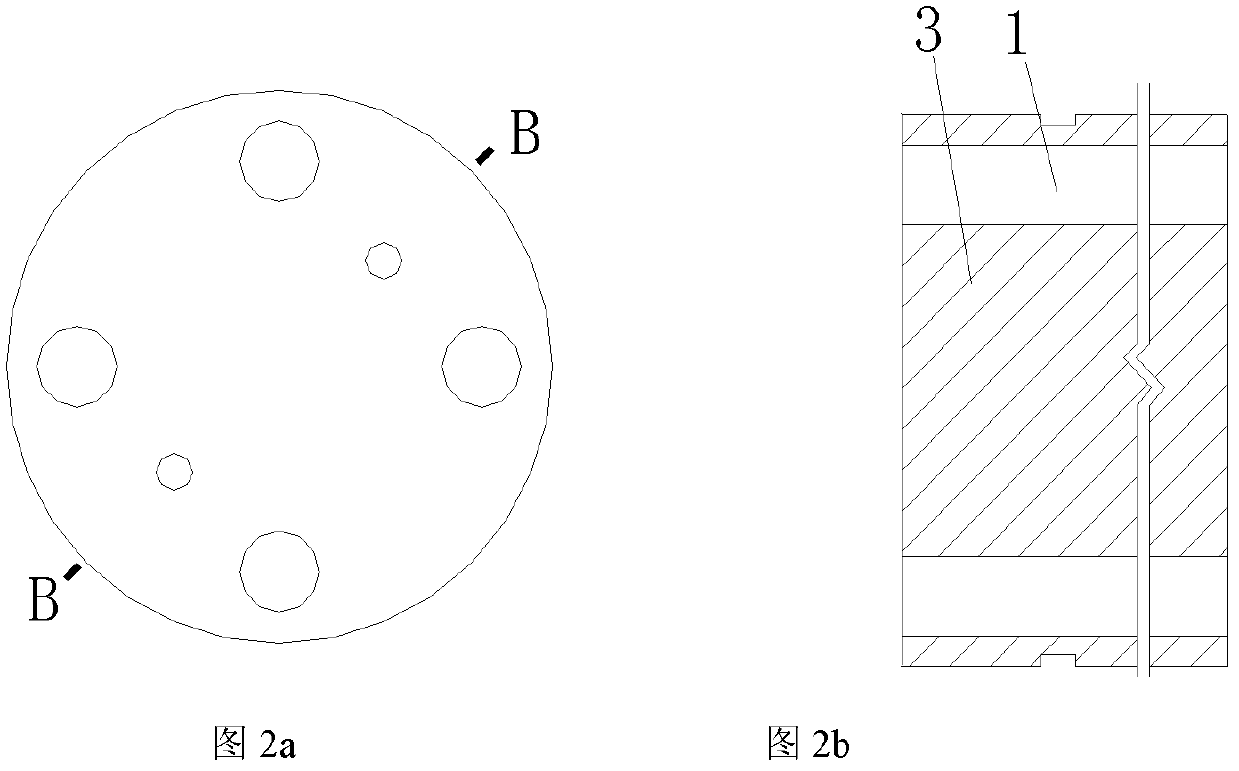

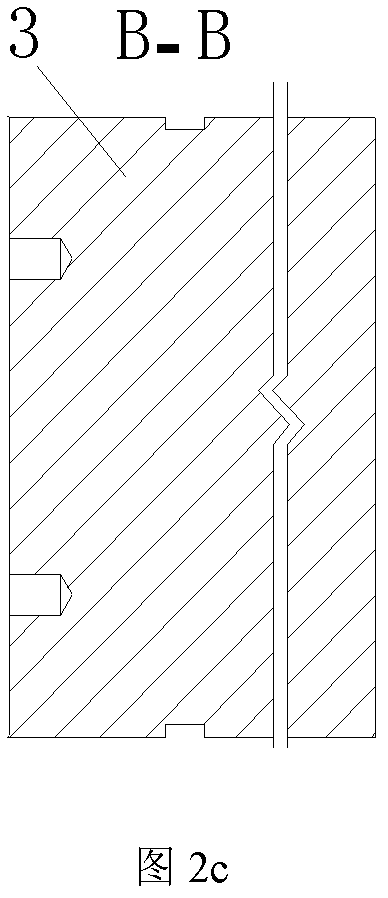

[0026] This embodiment includes the extrusion cylinder liner 3, the convex mold 4 and the concave mold 7. The end surface of one end of the male mold 4 is connected to one end surface of the lining 3 of the extrusion cylinder through a connecting pin 12; the end surface of the other end of the male mold 4 is connected to one end surface of the female mold 7 through an inner hexagonal fastening bolt 11 and a connecting pin 6. During the connection, the outlets of the four metal flow channels in the lining 3 of the extrusion cylinder are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com