Welding screw moulding die

A technology for forming molds and screws, applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems such as the failure of the bolt bonding surface and the installation part to closely fit, the inability to play a waterproof role, and the reduction of welding reliability. To achieve the effect of simple structure, improve work efficiency and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

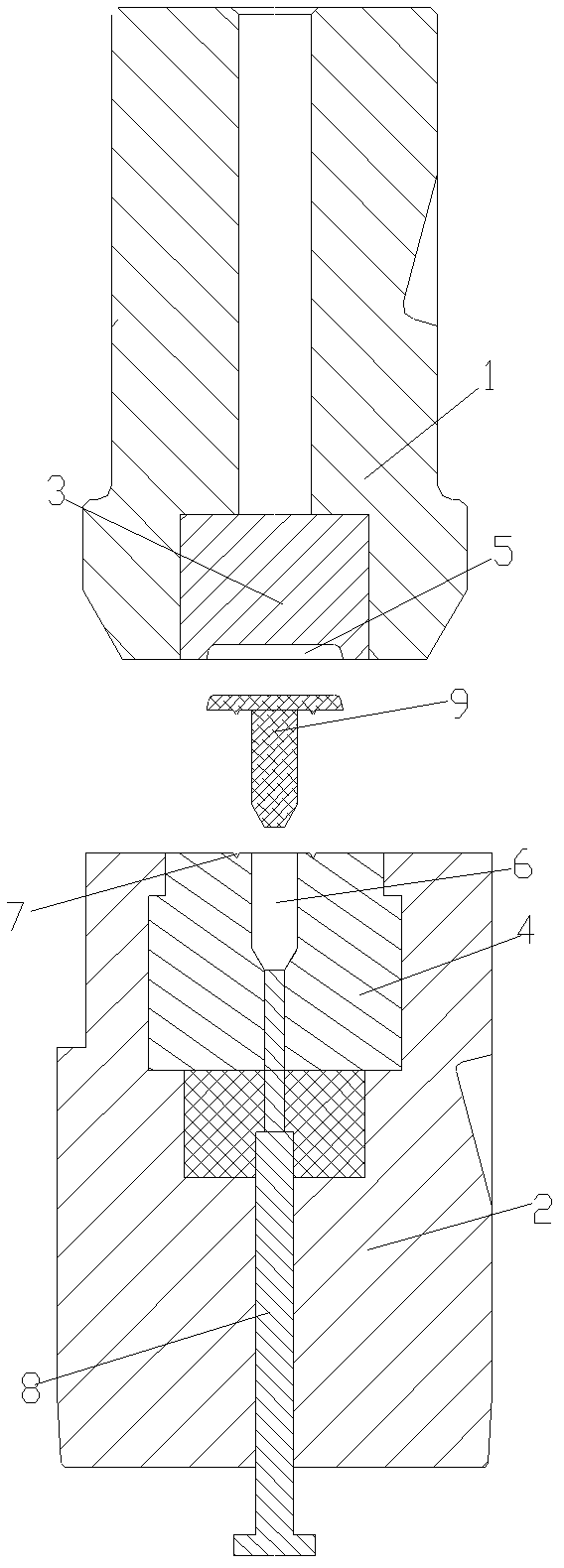

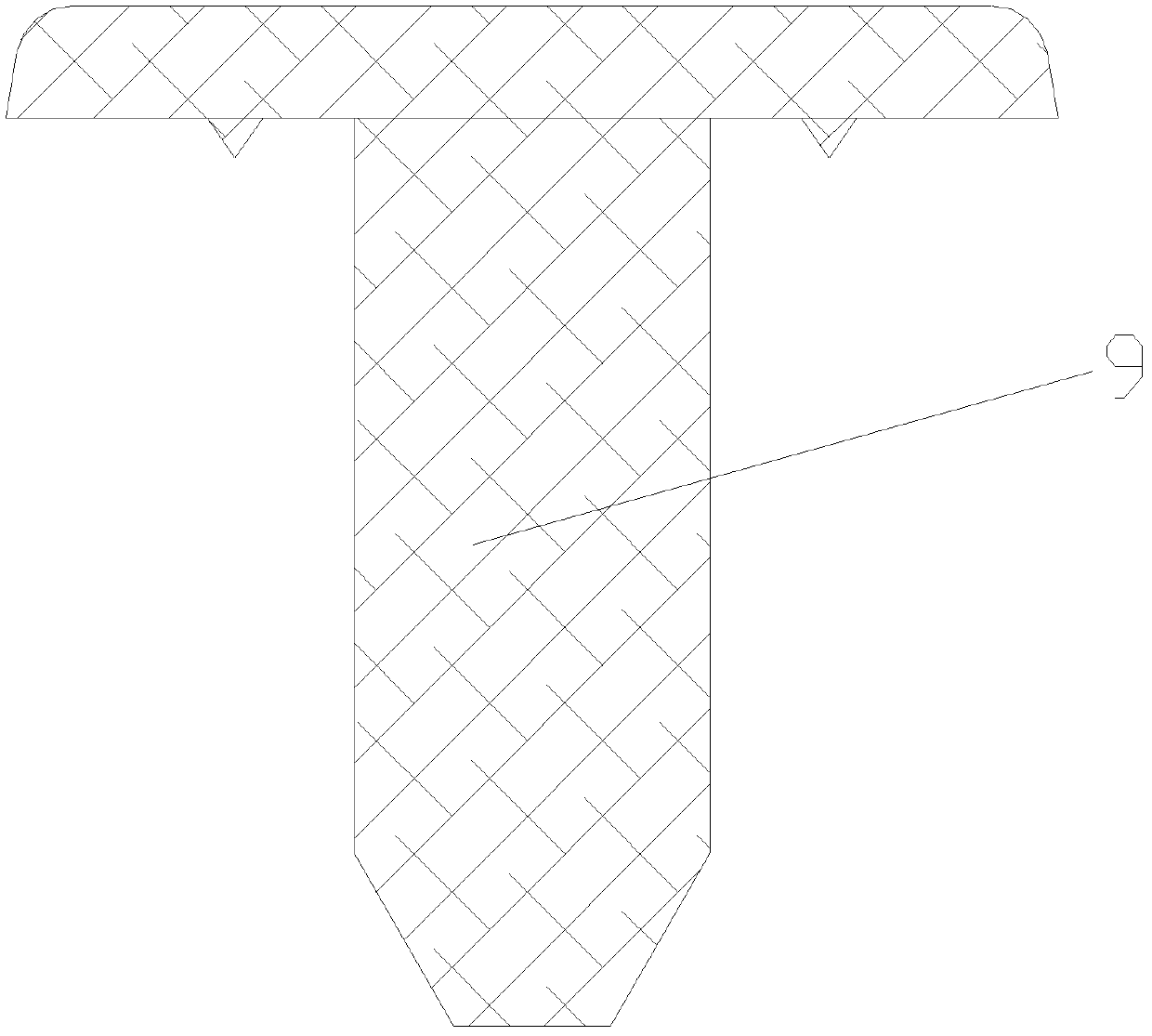

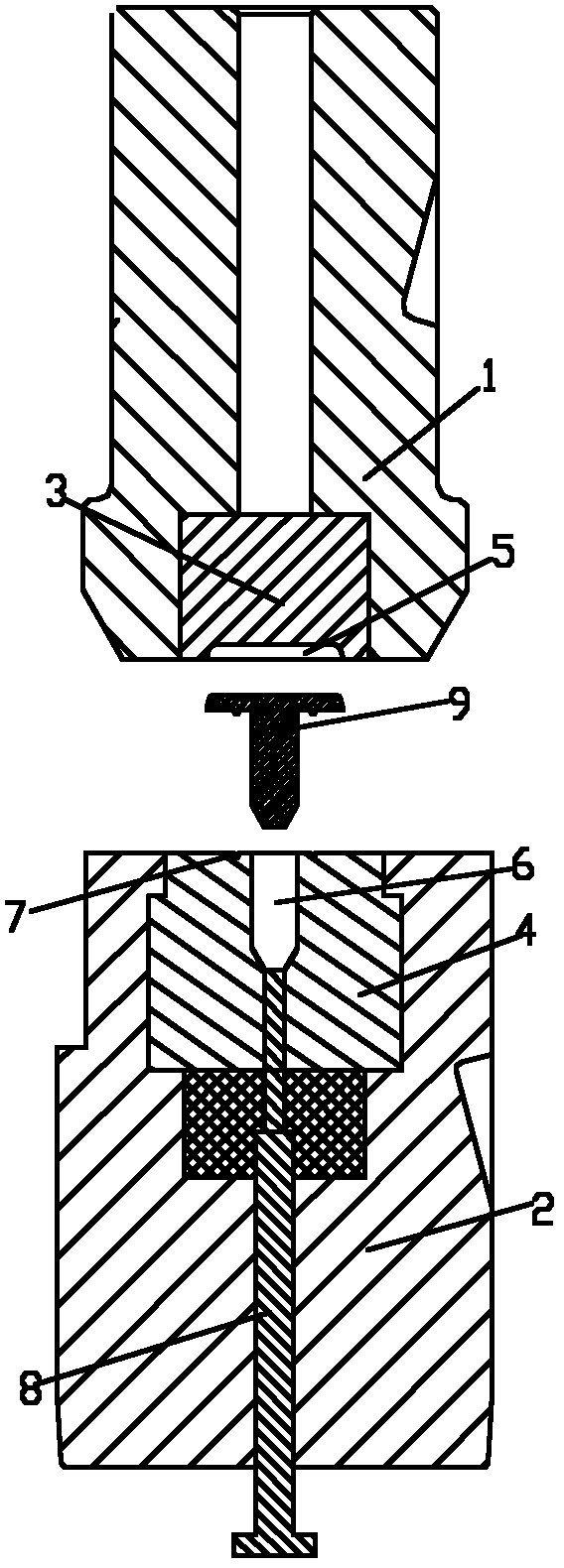

[0012] attached figure 1 , 2 It is a kind of welding screw molding die according to the present invention, comprising an upper mold 1, a lower mold 2 and a product ejection pin 8 arranged in the lower mold 2, the upper mold 1 is provided with an upper mold core 3; There is a screw head molding cavity 5 at the bottom of the mold core 3; a lower mold core 4 is arranged inside the lower mold; a screw shank forming cavity 6 is arranged inside the lower mold core 4; the bottom of the screw shank forming cavity 6 is It is a conical cavity; the end surface of the lower mold core 4 is provided with an annular groove 7; the cross section of the annular groove 7 is V-shaped.

[0013] The above-mentioned embodiments are only to illustrate the technical conception and characteristics of the present invention. Substantial equivalent changes or modifications shall fall within the protection scope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com