Method for radially and axially rolling and forming large-sized double-edge stepped ring parts

A technology of axial rolling and stepped rings, which is applied in metal rolling and other directions, can solve the problems of high energy consumption, low efficiency, and weakened ring performance in forging and reaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

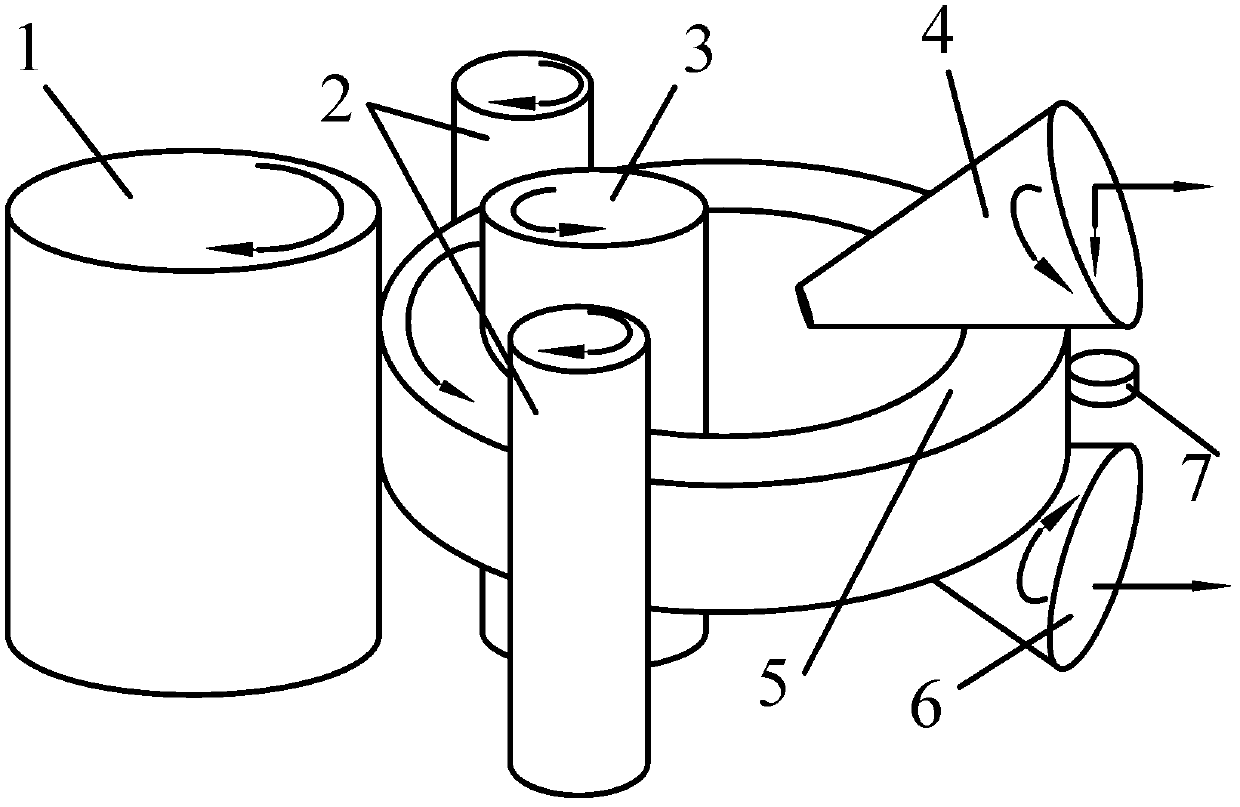

[0059] Figure 1-7 Shown, for adopting radial and axial ring rolling machine forming according to the present invention such as figure 2 The large double-sided stepped ring is shown in the radial and axial roll forming method of the large inner stepped ring.

[0060] figure 1 The middle ring 5 is placed horizontally between the driving roller 1 and the core roller 3 of the radial and axial ring rolling machine, and the guide rollers 2 on both sides guide the ring 5 from the front and rear directions; the upper tapered roller 4 is tapered, and the ring 5 The horizontal upper end surface of the ring is processed; the lower tapered roller 6 is tapered, and the horizontal lower end surface of the ring 5 is processed; the measuring roller 7 measures it in real time from the right side of the ring 5.

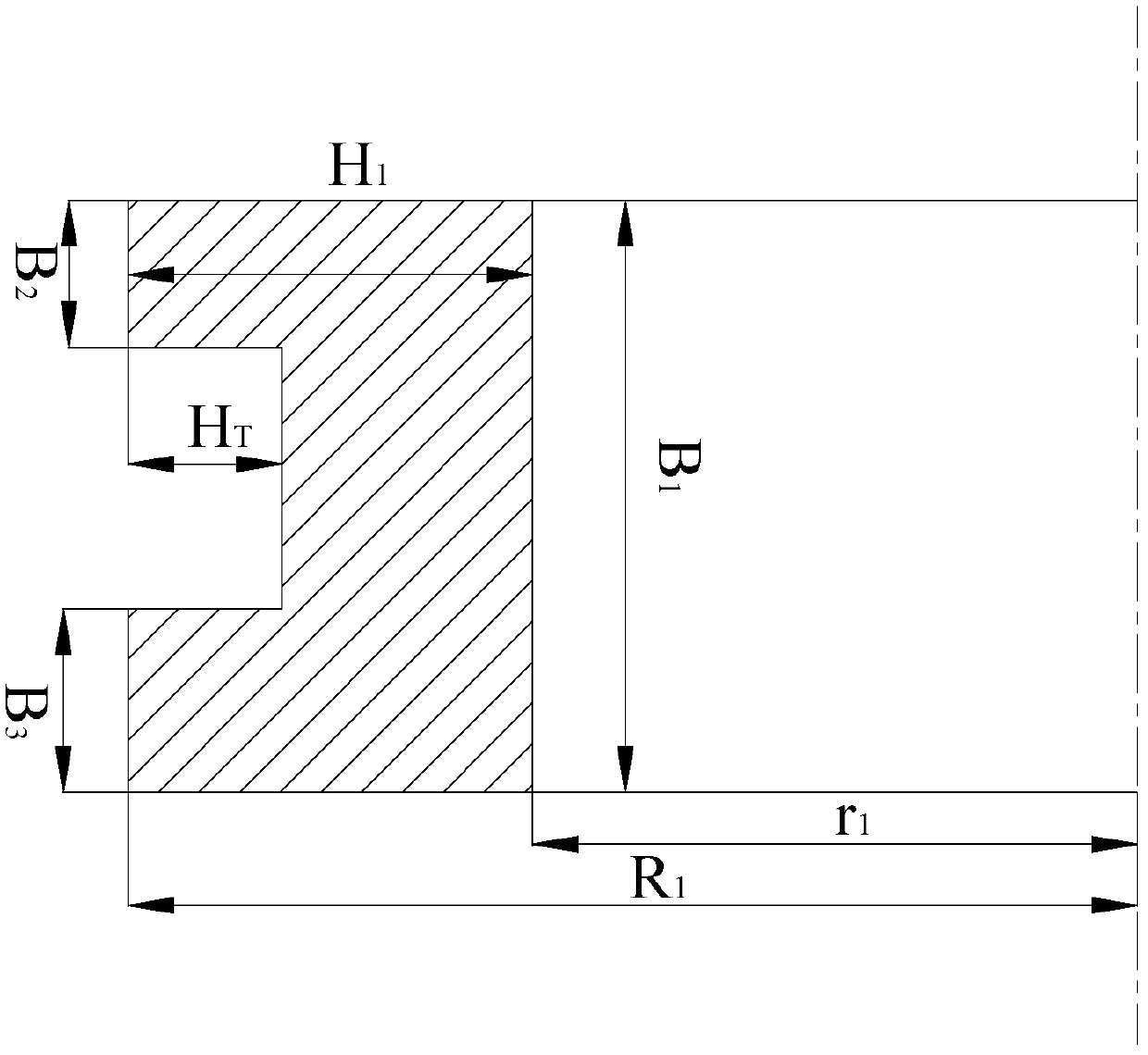

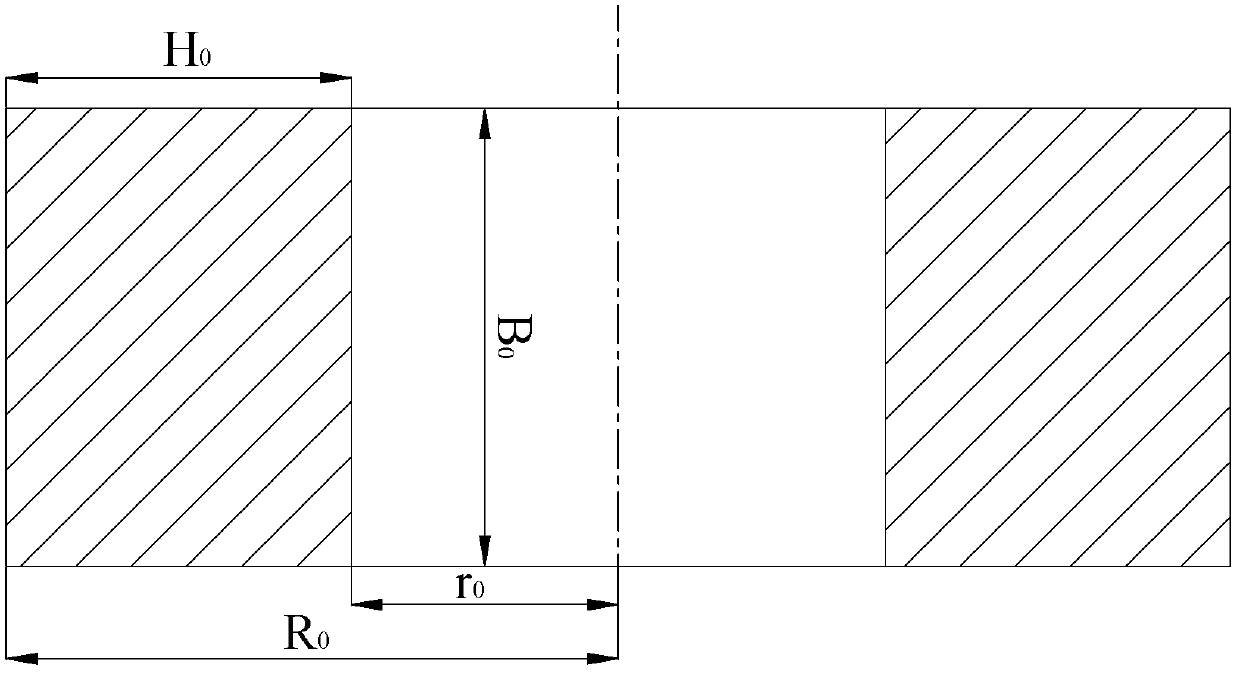

[0061] Such as figure 2 The geometric dimensions of the large double-sided step ring shown are: outer radius R 1 is 779mm, inner radius r 1 662mm, width B 1 310mm, two boss th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com