Automatic riveting device

A riveting device and rivet technology are applied in the field of automatic rivet riveting devices for cold extrusion of steel plates, which can solve the problems of difficult threaded holes for thin and light steel plates, low work efficiency, and complicated operations, and achieve low manufacturing costs, simplify work, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

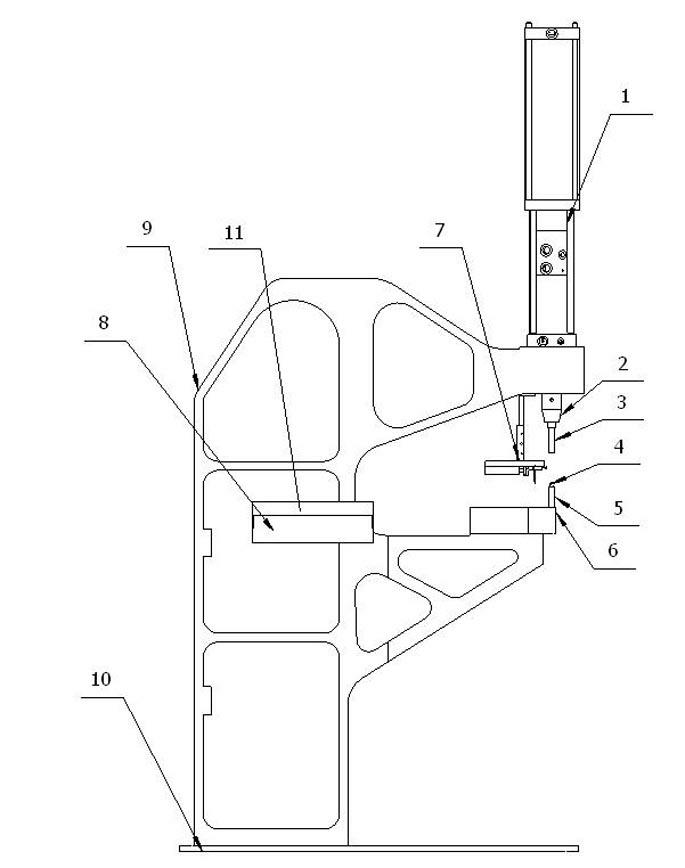

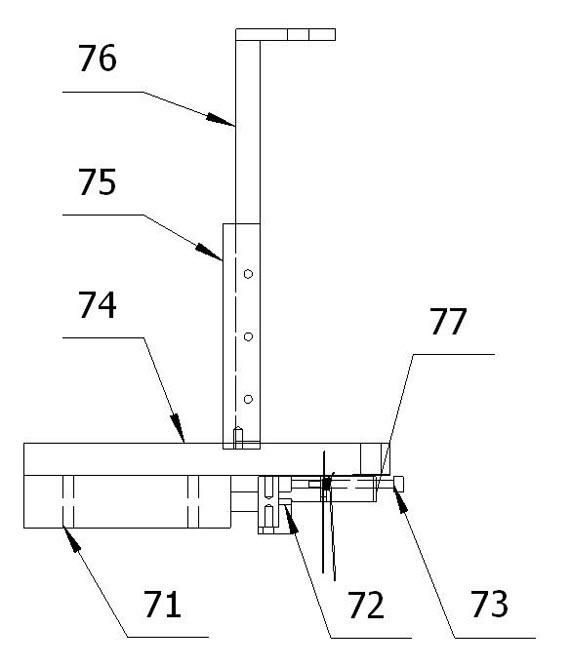

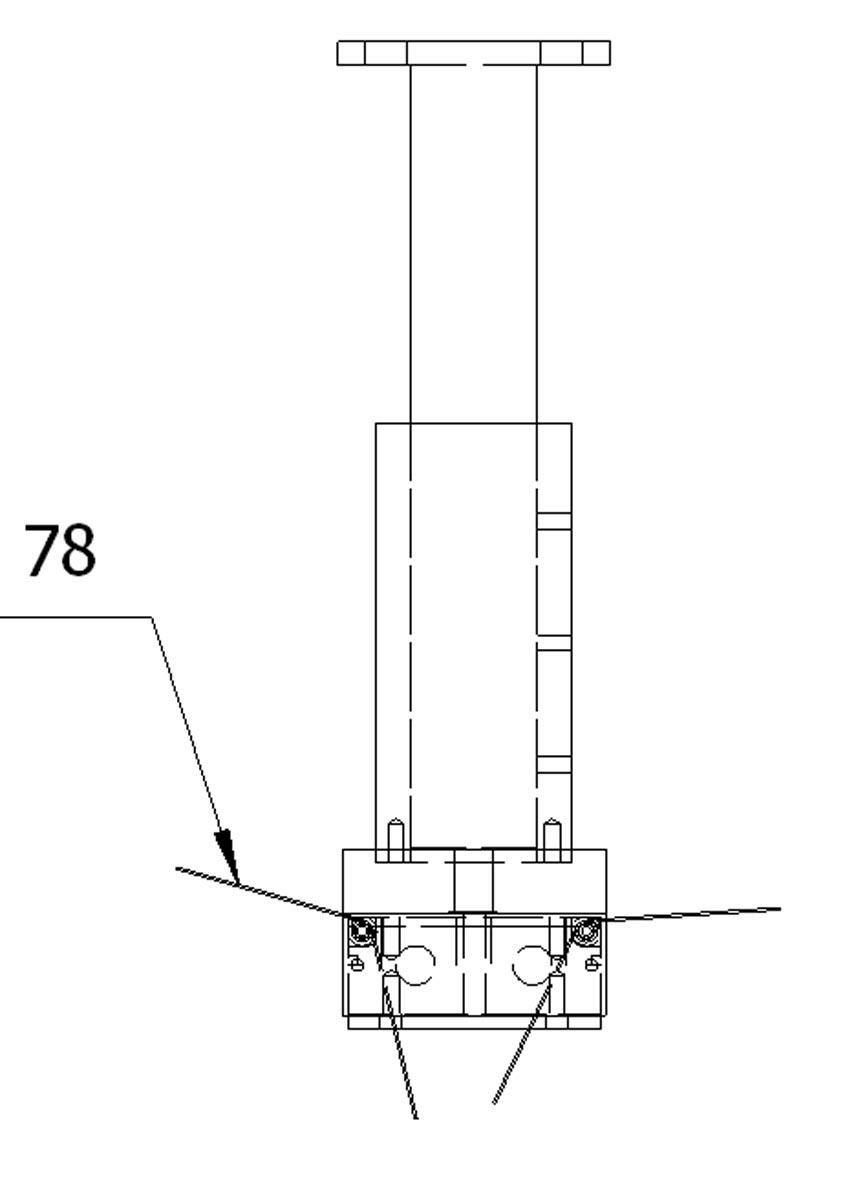

[0017] Such as Figure 1-4 A kind of automatic rivet riveting device shown, this automatic rivet riveting device comprises: booster cylinder 1, transition head 2, pressure head 3, core 4, lower mold 5, lower mold base 6, nail feeding device 7, support 8. Bed body 9, base 10 and vibrating plate 11; the nail feeding device 7 includes: cylinder 71, feeding moving seat 72, rotating screw 73, cylinder seat 74, adjustable groove plate 75, connecting plate 76, rotating door 77 , Spring 78, cylinder block 74 is provided with drop hole 79.

[0018] The connections of the above components are as follows:

[0019] The bed body 9 is fixed on the base 10, a support 8 is fixed on the bed body 9, a vibrating plate 11 is fixed above the support 8, and one end opening of the vibrating plate 11 is connected with the nail feeding device 7; the upper end of the bed body 9 is fixed to pressurize Cylinder 1 cylinder body, transition head 2 is installed at the lower end of booster cylinder 1, inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com