Automatic grinding/slitting system for refractory bricks

A technology of refractory bricks and refractory bricks, which is applied in the field of refractory brick manufacturing, can solve the problems of low production efficiency, high labor intensity, and large human injury, and achieve the effects of easy installation and maintenance, high processing efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

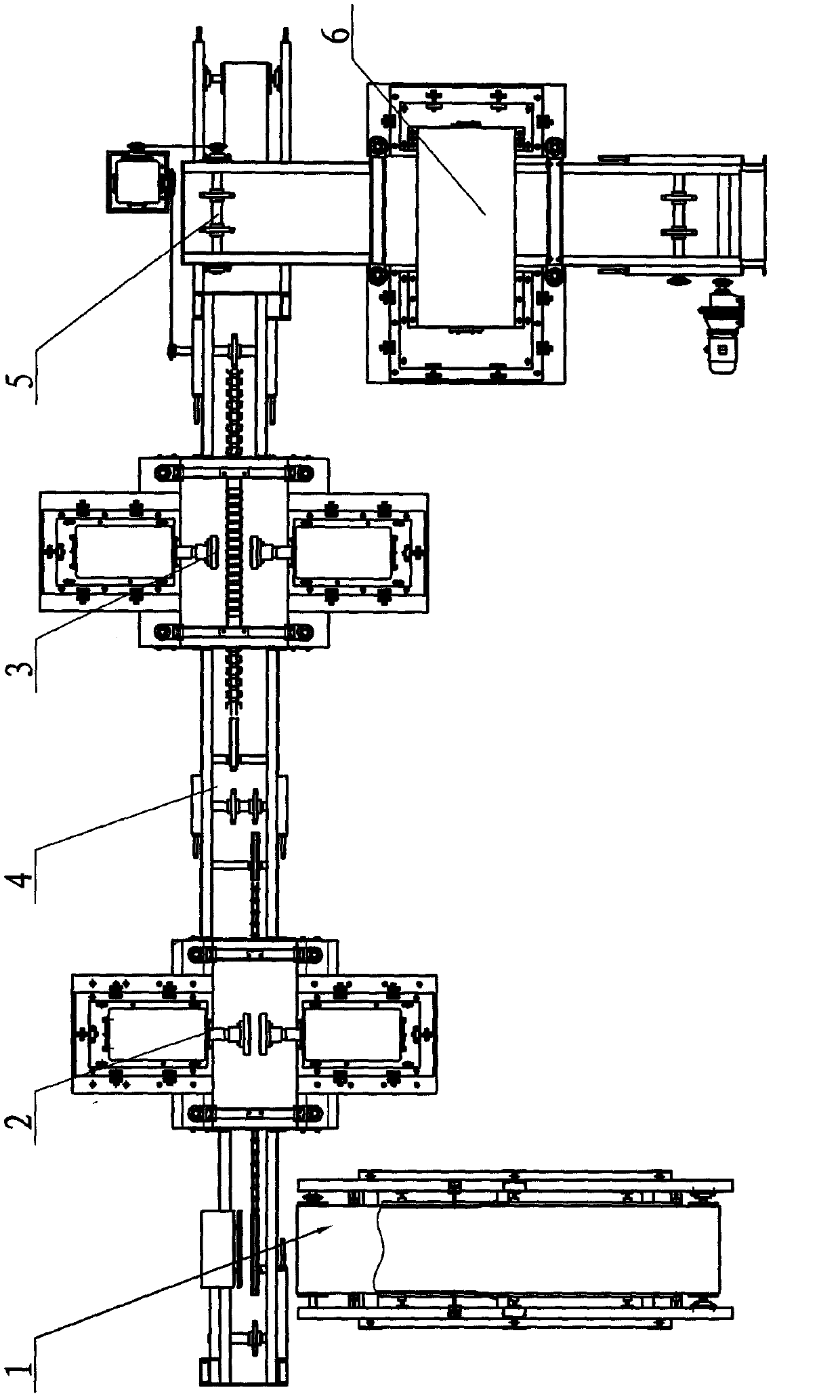

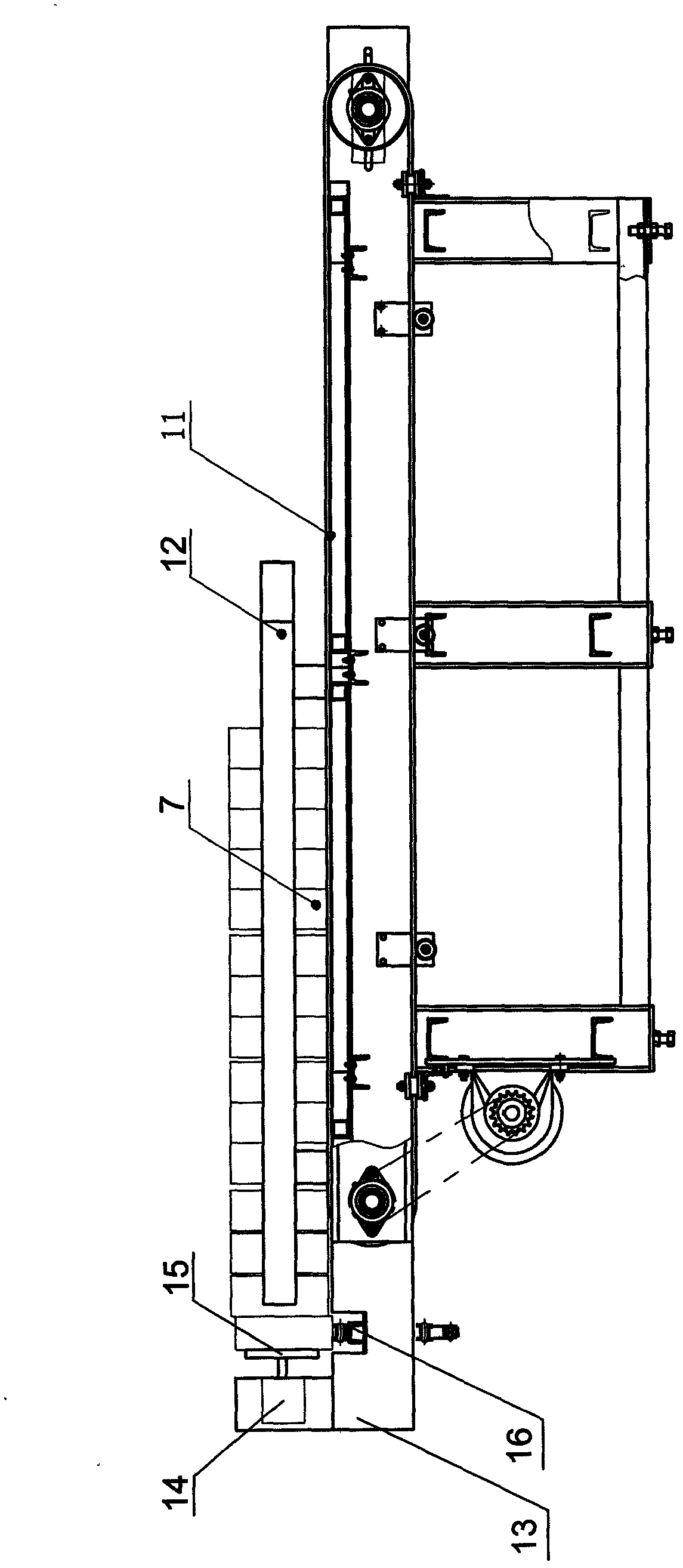

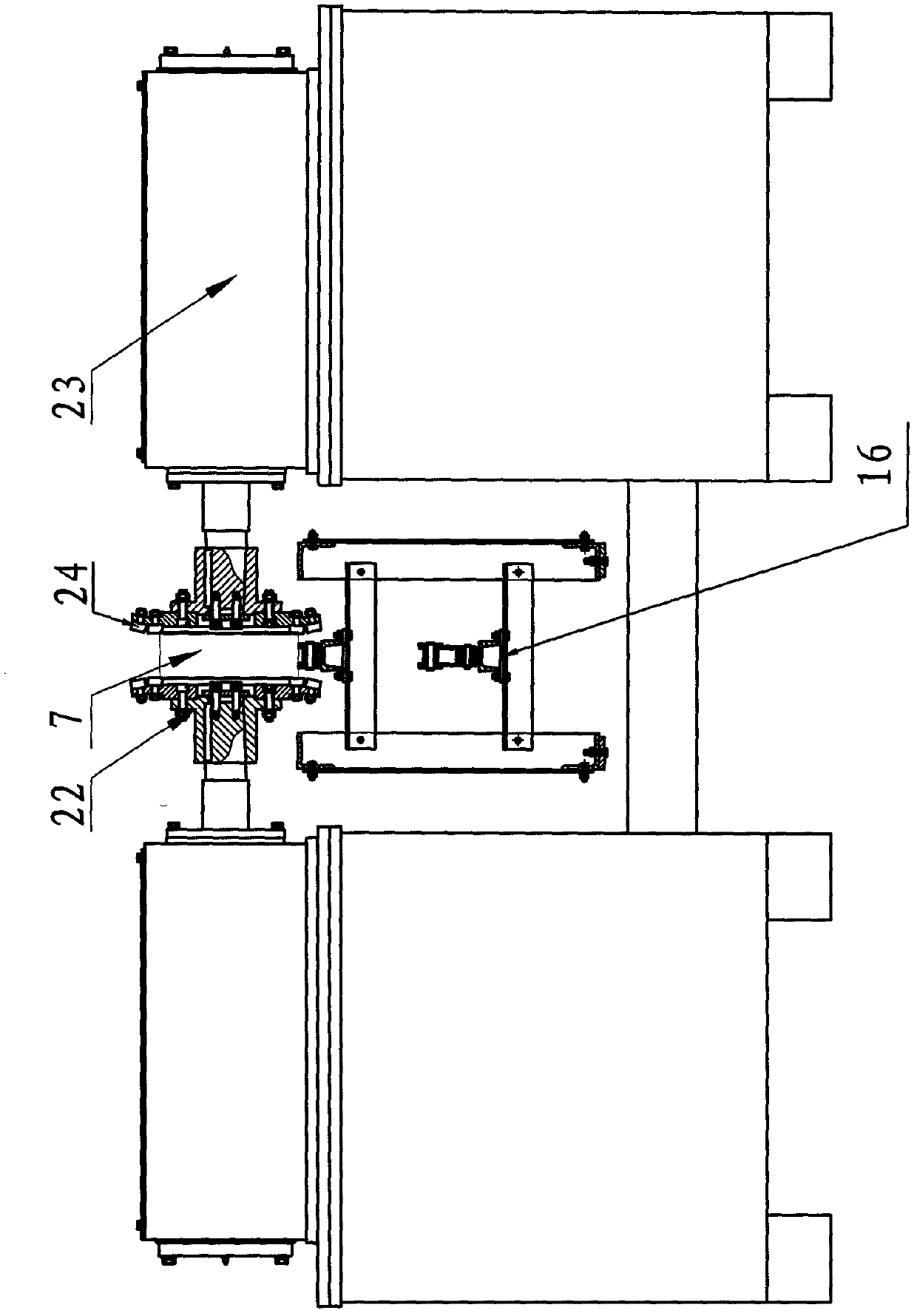

[0025] see figure 1 , an automatic grinding / slitting system for refractory bricks, including:

[0026] An automatic billet feeding device 1 for intermittently feeding the refractory brick grinding device;

[0027] Two first refractory brick double-sided grinding devices 2 and second refractory brick double-sided grinding devices 3 for continuous grinding of refractory bricks;

[0028] A refractory adobe turning device 4 for automatically turning the refractory adobe from the large surface vertically to the large surface horizontally;

[0029] A refractory adobe synchronous steering device 5 used to make the transmission direction of the refractory adobe automatically horizontally turn to the left or right by 90° and then continue to transfer;

[0030] An automatic slitting system 6 for cutting or slitting refractory bricks.

[0031] Among them, the automatic billet feeding device 1 is connected with the first refractory brick double-sided grinding device 2, the first refrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com