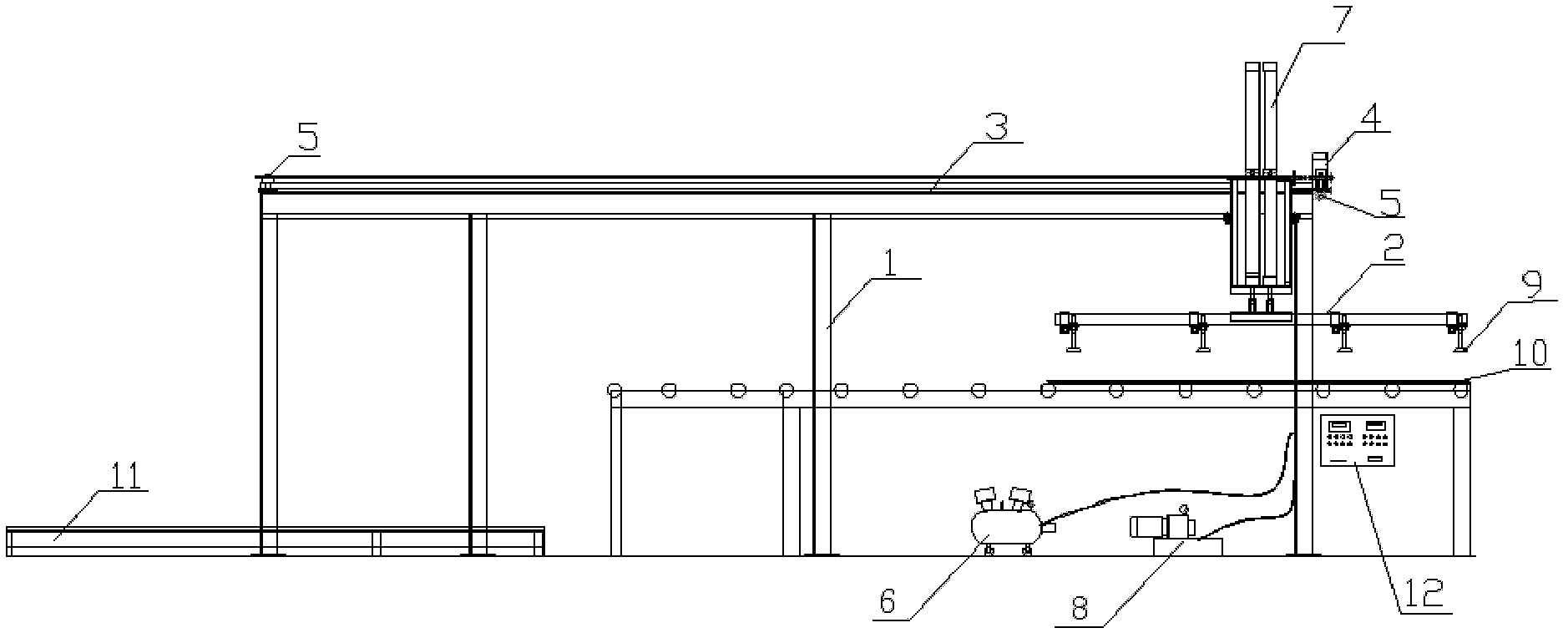

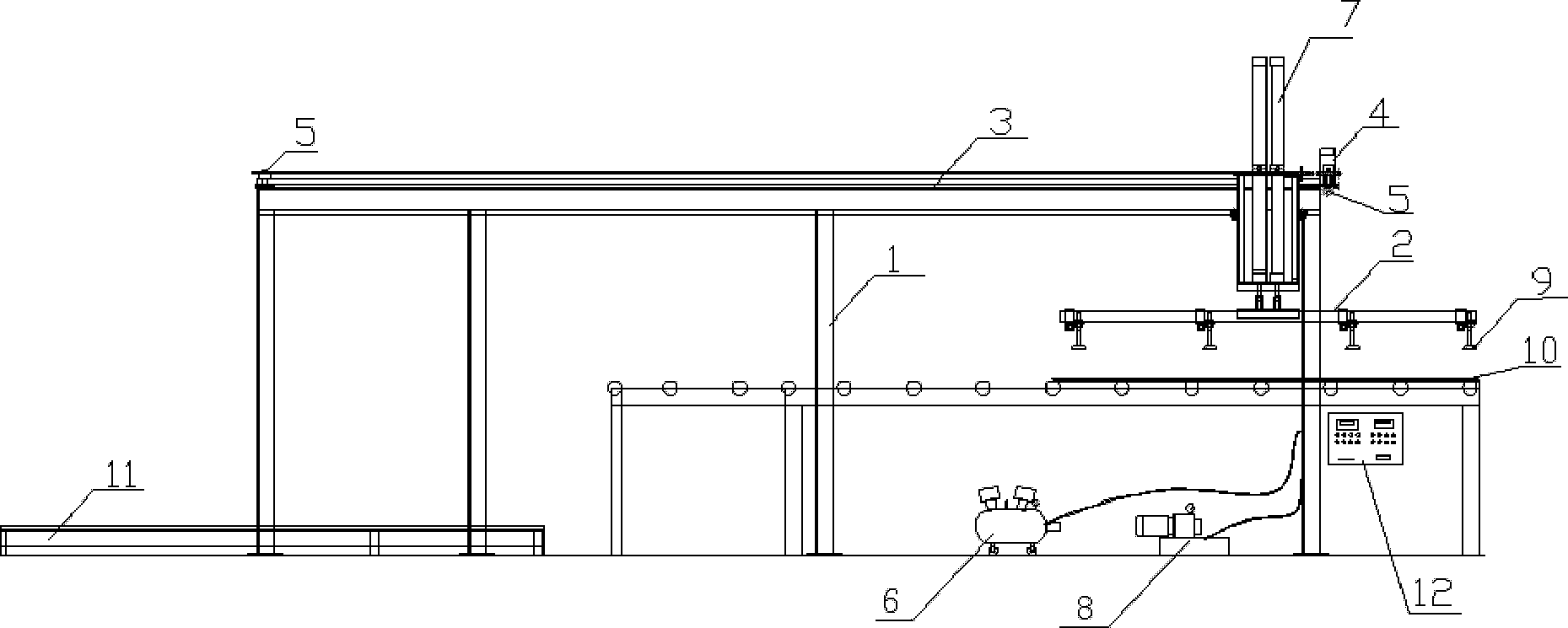

System device for automatic sucking-up handling plates

A technology of handling system and pneumatic system, which is applied in the field of automatic adsorption handling system device, can solve the problems of complex structure, increase of production cost, increase of device volume, etc., and achieve the effect of saving manpower and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The plate automatic adsorption and transporting system completes a transport cycle action: after the electrical control box 12 is turned on and powered on, the adsorption rack automatically returns to the position where the suction plate is prepared, and the cylinder 7 goes down and drives the adsorption rack 2 to go down. After reaching the position of the suction plate, the cylinder 7 stops descending, after the sucker 9 sucks the plate, the cylinder 7 and the adsorption frame 2 go up, when the cylinder 7 reaches the position of the track 3, stop rising, the motor drives the 4 adsorption frame to walk and carry, when the adsorption frame 2 reaches the position of the base 11, stop walking, The cylinder 7 drives the adsorption frame 2 to go down, the suction cup 9 releases the plate 10, then the cylinder 7 and the adsorption frame 2 go up, the cylinder 7 stops, the driving motor 10 drives the adsorption frame 2 to go back, and returns to the initial position, the adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com