Low-temperature anti-vapour food preservative film

A food preservation and anti-fog technology, applied in the fields of food preservation, fruit and vegetable preservation, food science, etc., can solve the problems of opacity and poor hydrophilicity of the preservative film, and achieve the effect of increasing light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Film preparation

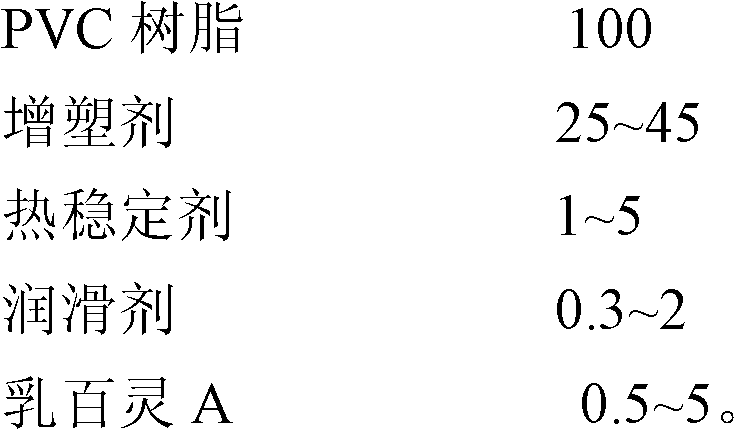

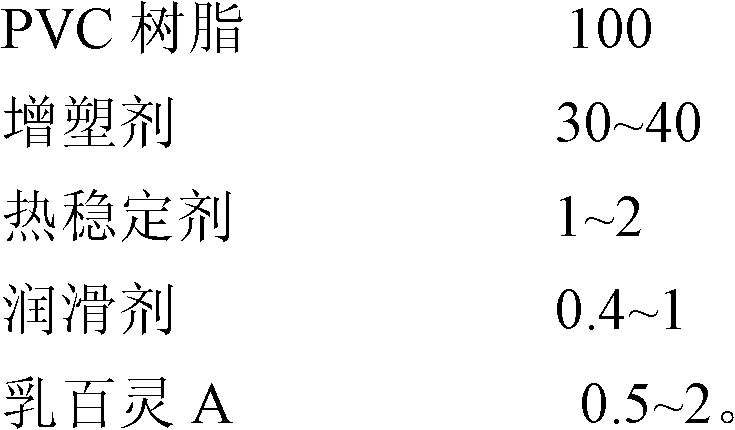

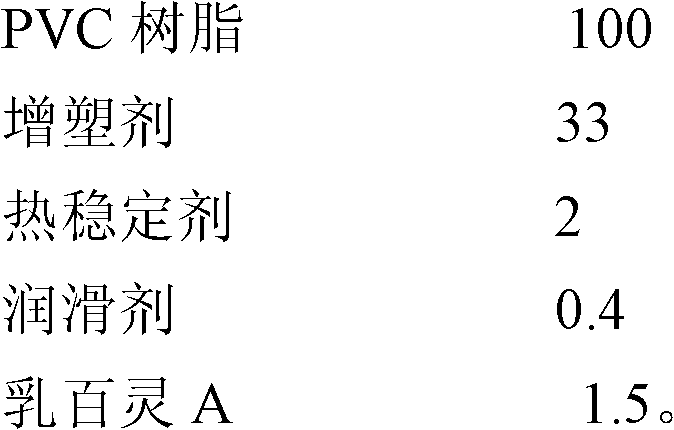

[0022] (1) Put the raw materials into the high-speed mixer according to the ratio shown in Table 1, knead until the temperature reaches 105°C, and put the output into the low-speed cooling mixer to cool to room temperature to obtain a mixed powder;

[0023] (2) Put the mixed powder into the hopper of the extruder. The hopper is equipped with a forced feeding device to prevent the powder from bridging, and the hopper seat strengthens the water-cooled device to prevent the powder from heat and adhesion;

[0024] (3) Extrusion blow molding adopts Φ65 extruder, screw length to diameter ratio 1:28, screw model is BM type (separate type), temperature control is (four-zone heating of the fuselage): zone one is 145℃, zone two is 160 ℃, three-zone 165℃, four-zone 170℃, flange 160℃, die head 170℃; blow molding method is flat extrusion and upward blowing, the inflation ratio is about 2~2.3, and the shape is set by air cooling;

[0025] (4) Rewinding to obtain a 0.05mm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com