Method for preparing copper and copper-alloy cast ingots by electroslag refining technology

A technology of electroslag refining and copper alloy, which is applied in the field of metallurgical casting, can solve the problems of low production efficiency, high energy consumption, high production cost, etc., and achieve the effects of high production efficiency, short process flow and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

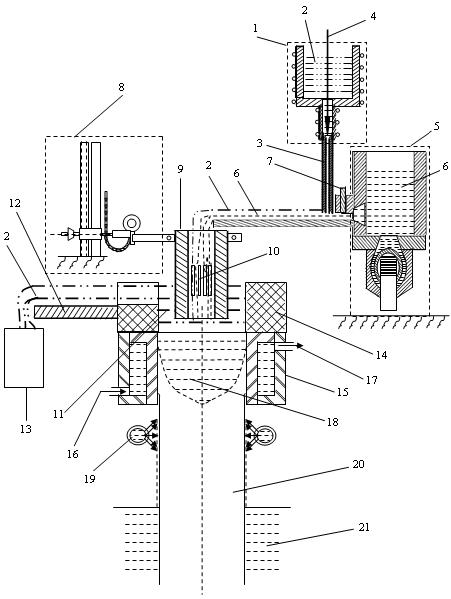

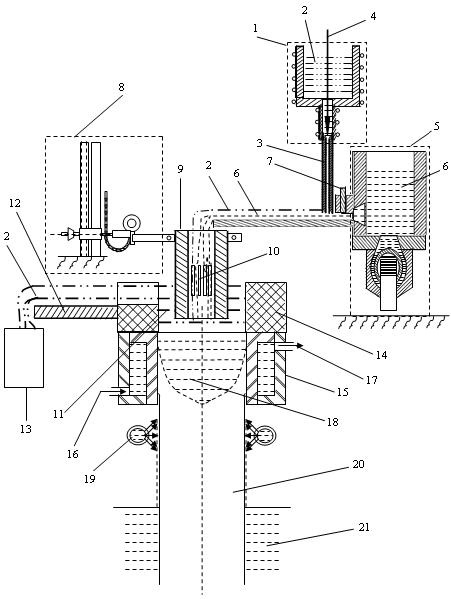

[0011] The method for preparing copper and copper alloy ingots by electroslag refining technology of the present invention is to transfer molten copper to a porous heating electrode through a launder, use a crystallizer to carry out water-cooled ingot casting three times after being heated by the porous heating electrode, and The electroslag liquid is passed into the tank, and the excess electroslag liquid in the crystallizer overflows into the slag bag. The temperature of the electroslag liquid 2 is controlled to be 50-80°C higher than that of the copper liquid, the density of the electroslag liquid is required to be 10-20% lower than that of the copper liquid, and the boiling point of the electroslag liquid is required to be higher than 1900°C.

[0012] now refer to figure 1 Specifically describe the scheme of the present invention:

[0013] The molten copper 6 melted by the induction furnace 5 or the reverberatory furnace is transferred into the porous heating electrode 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com