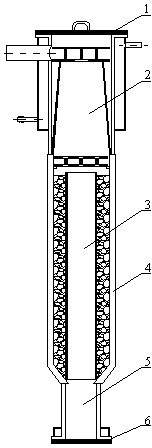

Slagging method for vertical retort magnesium smelting and vertical retort magnesium smelting device using same

A technology for smelting magnesium and vertical tanks, which is applied to lighting and heating equipment, furnaces, and electric charge control, etc., which can solve the problems of reducing the amount of material in a single tank, violently stirring the gas in the reduction tank, and not being able to remove the slag smoothly, so as to reduce the Dust, improved working conditions, controllable slag discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0026] The slag removal method of vertical pot magnesium smelting of the present invention is as follows:

[0027] Open the upper cover, take out the accessories in the reduction tank, and then close the upper cover;

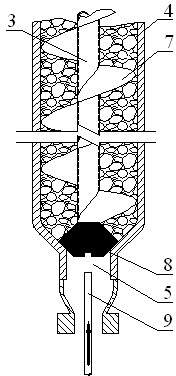

[0028] Such as figure 2 As shown, open the lower cover, place the slag discharge device below the slag discharge port 5, adjust the rotating ejector rod 9 of the slag discharge device, and the rotating ejector rod 9 passes through the lower end of the slag discharge port 5 and moves upward;

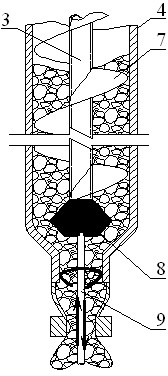

[0029] Such as image 3 As shown, the rotating mandrel 9 tops the cock 8, opens the slag outlet 5, and removes the slag; at the same time, the cock 8 in contact with the rotating mandrel 9 drives the center pipe 3 with the blade 7 to rotate, lift or Lifting and lowering while rotating, relying on the blade 7 to clean the slag on the inner wall of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com