Wind power H-beams and production method thereof

A production method and technology for H-beams, applied in temperature control, metal rolling, etc., can solve problems such as unfavorable product dimensions and toughness, product cracks, large residual stress, etc., and achieve excellent laminar tear resistance and corrosion resistance. , Excellent internal structure and surface quality, excellent toughness matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

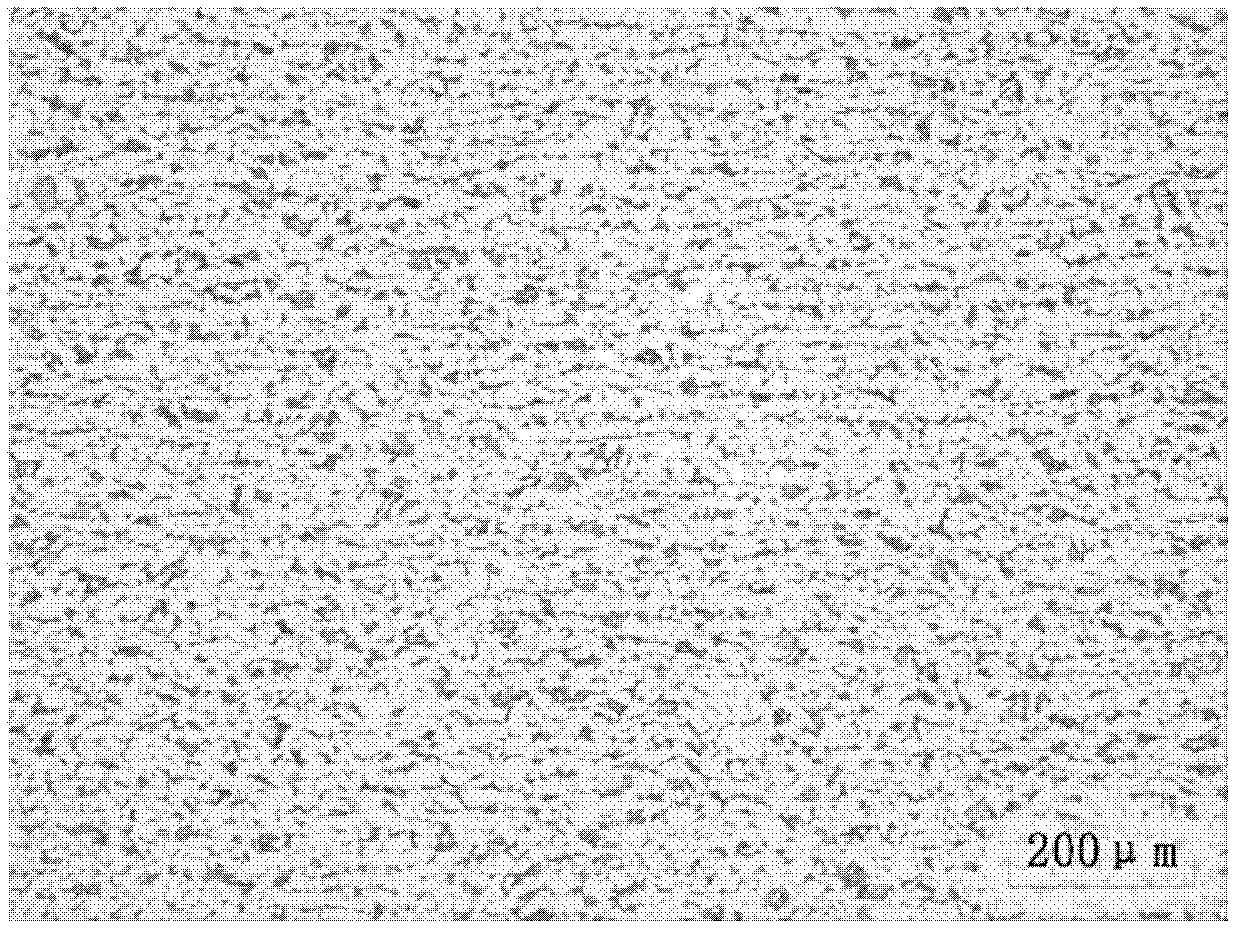

Image

Examples

example 1

[0046] In this example, H-beams for wind power are produced through molten iron pretreatment, top-bottom combined blowing converter smelting, LF refining, BB1 shaped billet continuous casting, two-phase zone controlled rolling and enhanced air cooling after rolling. Details are as follows.

[0047] Desulphurization and desiliconization of hot metal strictly implement the process regulations, sulfur is controlled at 0.013%, silicon is controlled at 0.46%, and the temperature is controlled at 1280°C. After the molten iron, 8 tons of high-quality steel scrap are added to the converter, and the slag-making material is added 3 minutes before the end point. The final slag alkalinity is 3.2, the oxygen supply time is 16 minutes and 40 seconds, the end point pressure gun is 70 seconds, and the tapping time is 4 minutes and 24 seconds. First use silicon-manganese alloy for deoxidation, the addition amount is 7.5kg / t 钢 , then add silicon calcium barium deoxidation, the addition amount ...

example 2

[0052] In this example, H-beams for wind power are produced through molten iron pretreatment, top-bottom combined blowing converter smelting, LF refining, BB1 shaped billet continuous casting, two-phase zone controlled rolling and enhanced air cooling after rolling. Details are as follows.

[0053] Desulphurization and desiliconization of hot metal strictly implements the process regulations, sulfur is controlled at 0.017%, silicon is controlled at 0.44%, and the temperature is controlled at 1280°C. After the molten iron, 8.9 tons of high-quality steel scrap are added to the converter, and the slag-making material is added 3 minutes before the end point. The final slag alkalinity is 3.2, the oxygen supply time is 16 minutes and 41 seconds, the end point pressure gun is 72 seconds, and the tapping time is 4 minutes and 20 seconds. First use silicon-manganese alloy for deoxidation, the addition amount is 7.6kg / t 钢 , then add silicon calcium barium deoxidation, the addition amou...

example 3

[0058] In this example, H-beams for wind power are produced through molten iron pretreatment, top-bottom combined blowing converter smelting, LF refining, BB1 shaped billet continuous casting, two-phase zone controlled rolling and enhanced air cooling after rolling. Details are as follows.

[0059] Desulphurization and desiliconization of molten iron strictly implements the process regulations, sulfur is controlled at 0.016%, silicon is controlled at 0.45%, and the temperature is controlled at 1270°C. After molten iron, 8.3 tons of high-quality steel scrap were added to the converter, and the slag-making material was added 3 minutes before the end point. The final slag alkalinity was 3.2, the oxygen supply time was 16 minutes and 21 seconds, the end point pressure gun was 69 seconds, and the tapping time was 4 minutes and 45 seconds. First use silicon-manganese alloy for deoxidation, the addition amount is 7.7kg / t 钢 , then add silicon calcium barium deoxidation, the addition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com