Multifunctional integrated floating debris control floating-tank system for hydraulic engineering

A water conservancy project, multi-functional technology, applied in the field of flotation control, can solve the problems of loss of flotation function, unfavorable technology integration development, failure to improve water environment, etc. development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

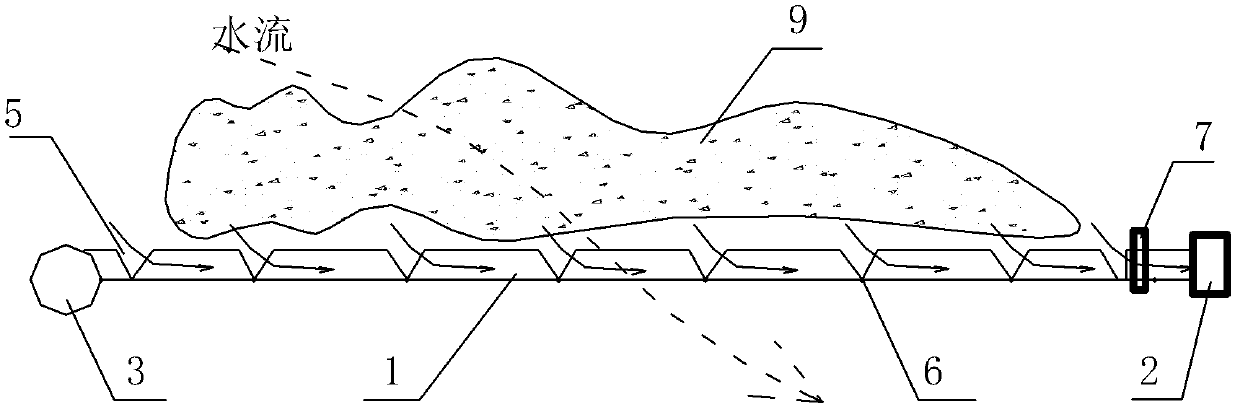

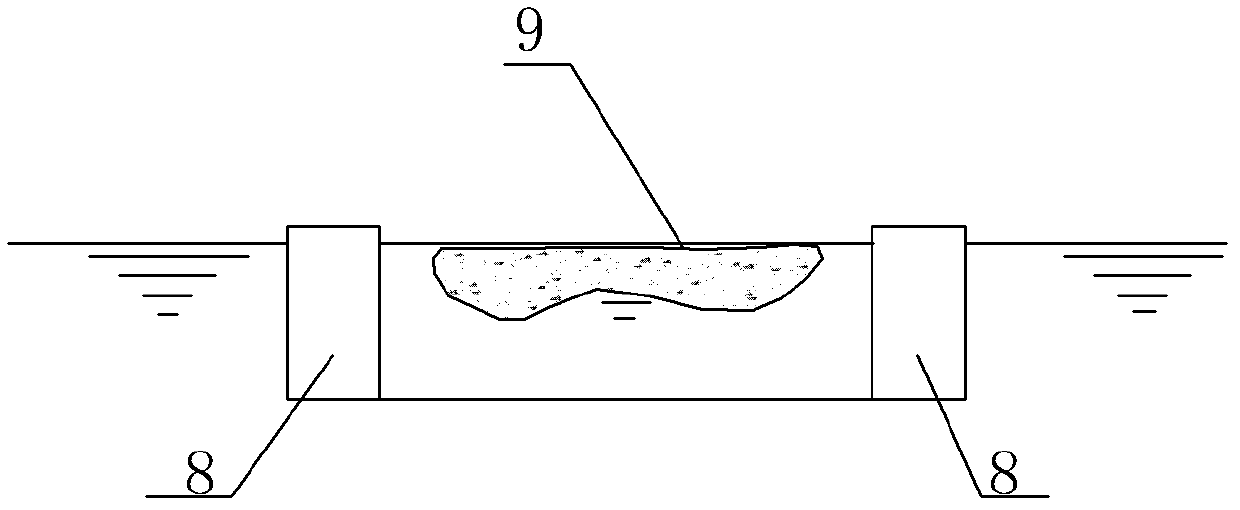

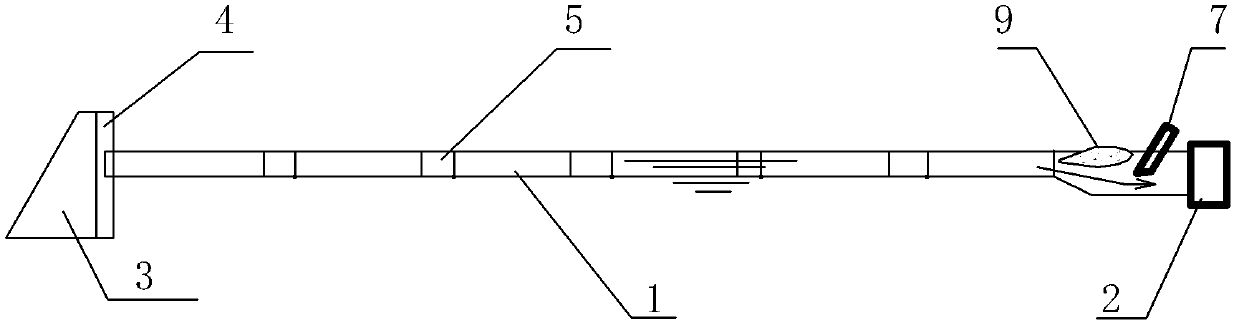

[0026] As shown in the picture- Figure 4 As shown, the multifunctional integrated floating tank system of the present invention mainly includes a floating tank 1, a positioning facility 3 and a floating cleaning machine 7, wherein: the floating tank 1 is composed of several single tanks hinged or flexibly connected by connecting hinges 6, There are cavities 8 on both sides of the tank body, a floating guide gate 5 is set along the floating side of the floating tank 1, one end of the floating tank 1 is connected to the positioning facility 3, and a chute is provided on the connecting side between the positioning facility 3 and the floating tank 1 4. Make the connection point of floating tank 1 move up and down with the change of water level. When the floating tank 1 is arranged in front of the power station, its outlet end is connected with the pivot drainage hole 2, and a cleaning and drifting machine 7 is set in the floating tank 1 close to the drainage hole 2. Generally, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com