Oil supply device of clamping cylinder of hydraulic static pile press

A technology of static pile driver and oil replenishing device, applied in fluid pressure actuating device, fluid pressure actuating system components, sheet pile wall, etc. Leakage, troublesome operation and other problems, to achieve the effect of high work efficiency, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the drawings and specific embodiments.

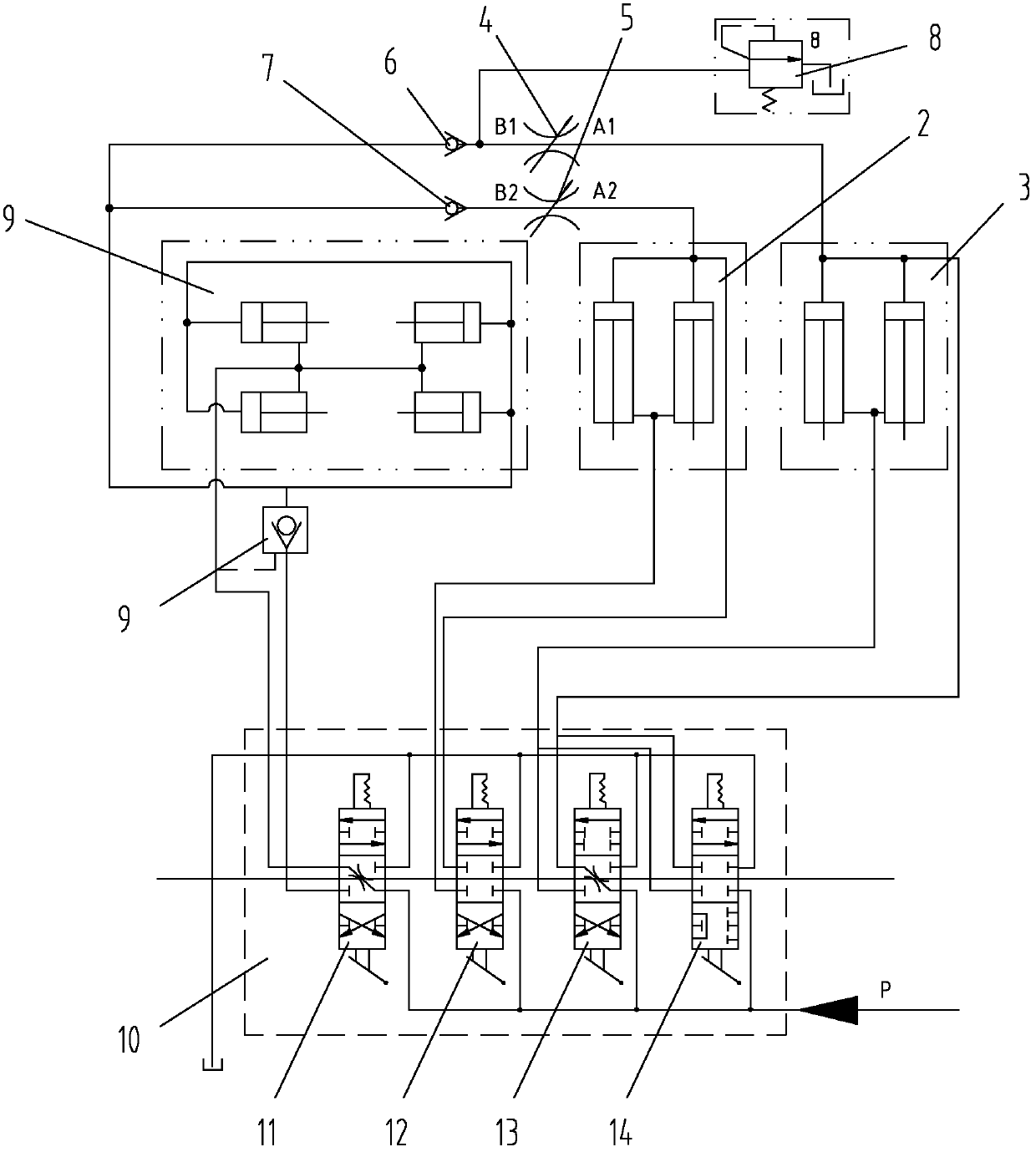

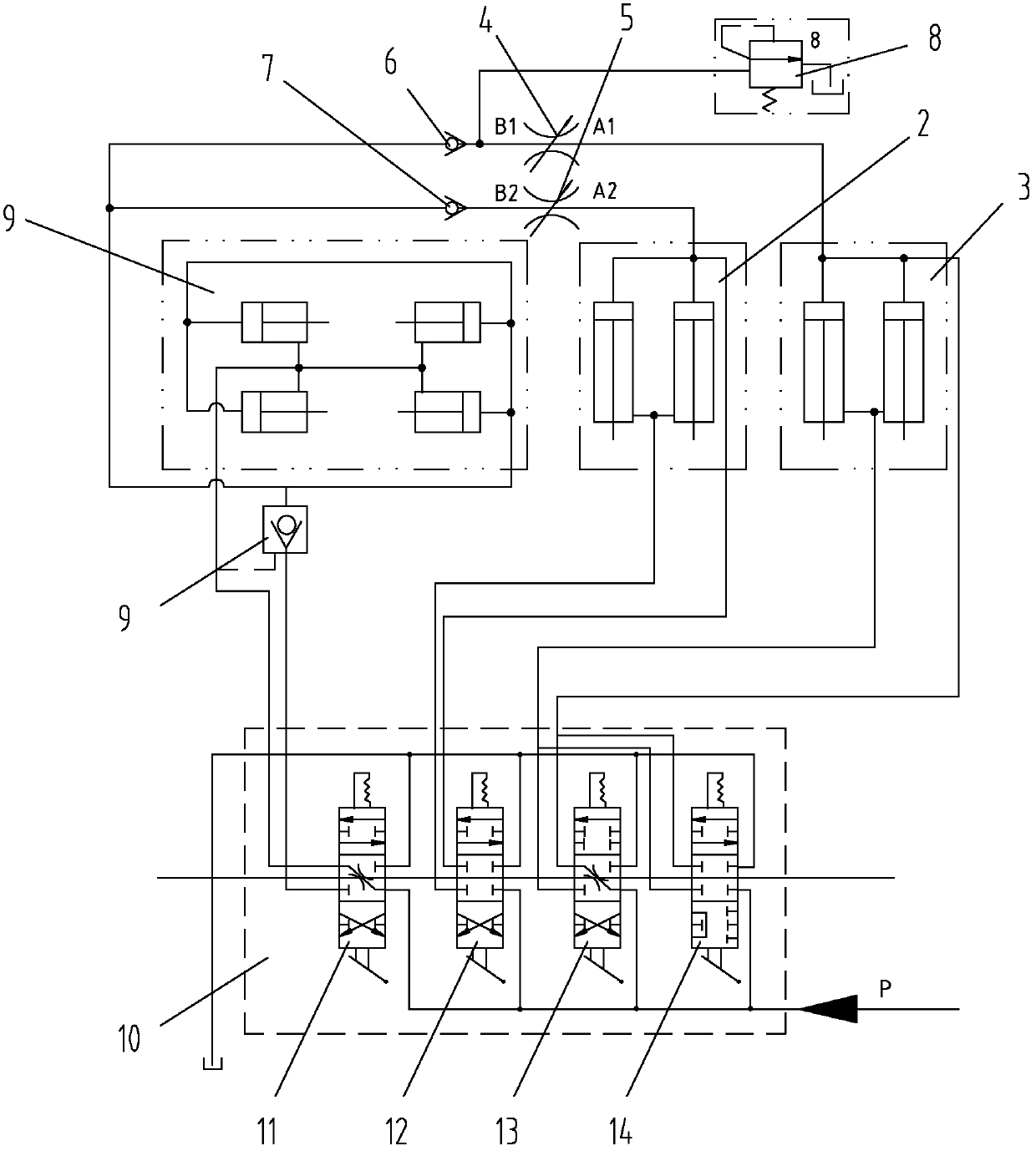

[0010] See figure 1 , The multi-way valve 10 is composed of a pile control valve block 11, a secondary pressure control valve block 12, a main pressure control valve block 13 and a gear control valve block 14. The rodless cavity of the pile clamp cylinder 1 and the first check valve 6 Connected to the oil outlet of the second check valve 7, the rod cavity of the clamping cylinder 1 is connected to the clamping control valve block 11 of the multi-way valve 10, and the rodless cavity of the clamping cylinder 1 is connected through the hydraulic check valve 9 Connected to the clamping control valve block 11 of the multi-way valve 10, the auxiliary pressure control valve block 12 of the multi-way valve 10 is connected to the auxiliary pile pressing cylinder 2, and the main pressure control valve block 13 of the multi-way valve 10 is connected to the main pile pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com