Flat low-pressure water valve assembly with small floating ball

A low-pressure water, flat-type technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve problems such as short service life, rough gaps, and reduced sensitivity, and achieve the effect of simplifying processing and installation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

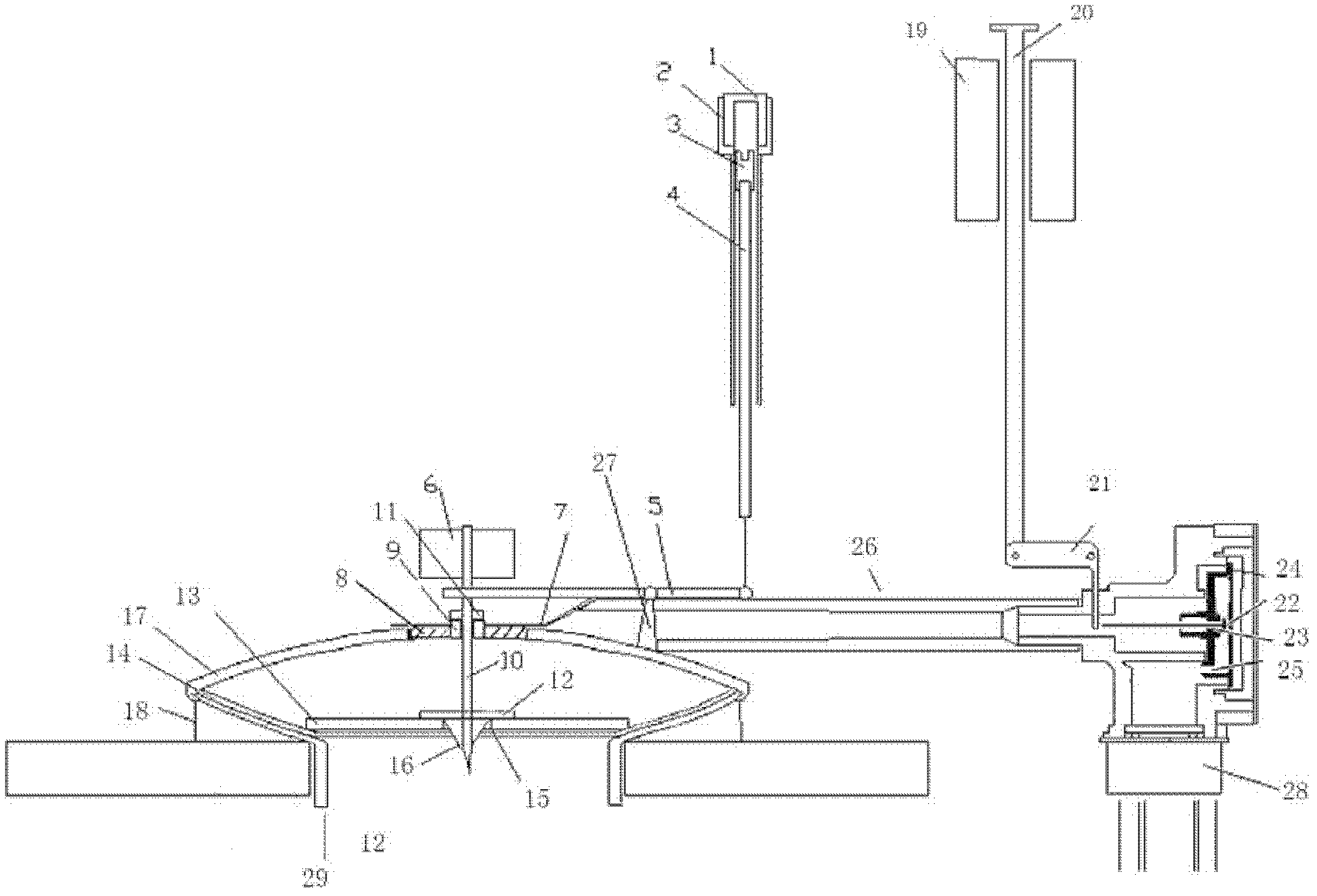

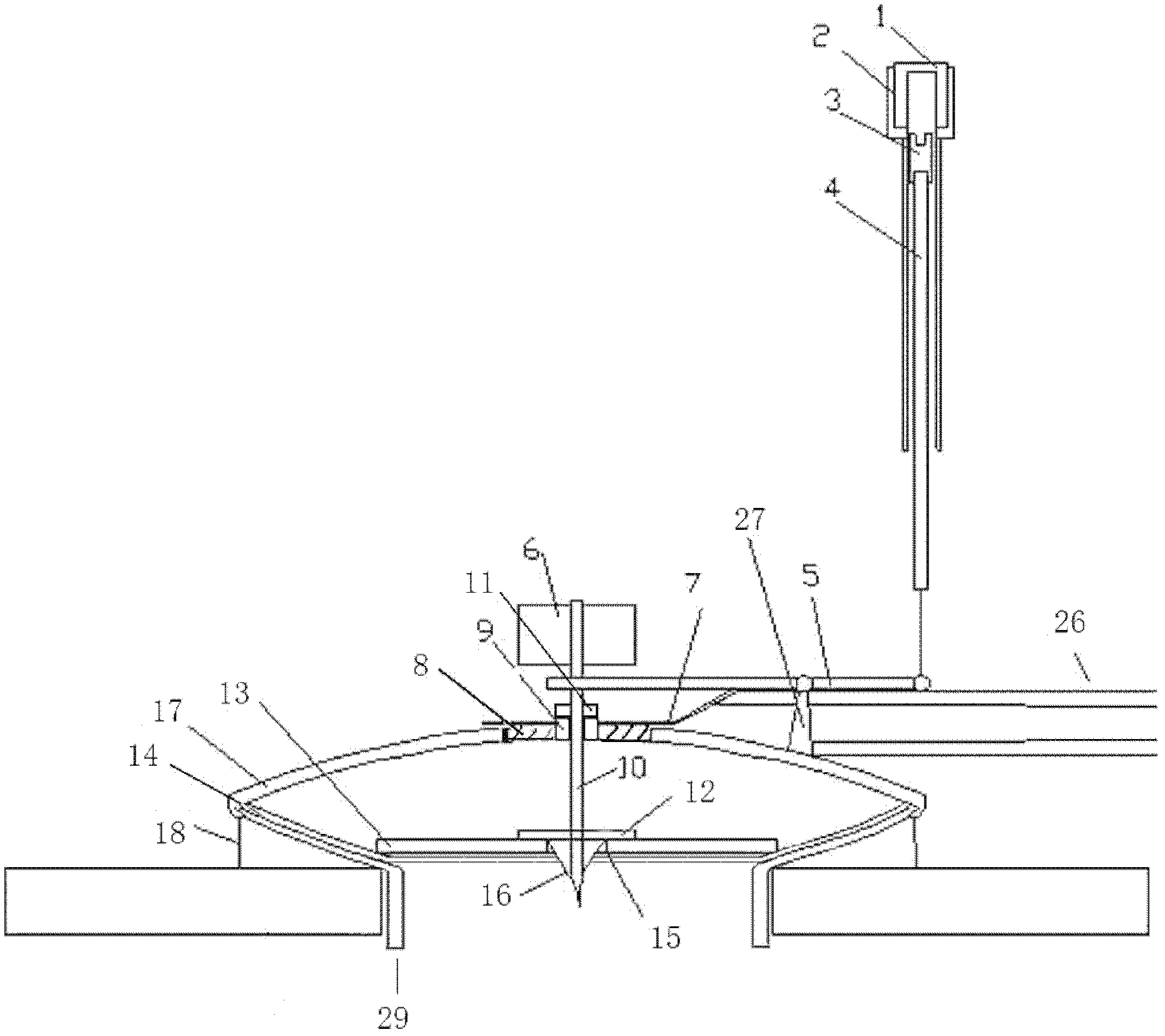

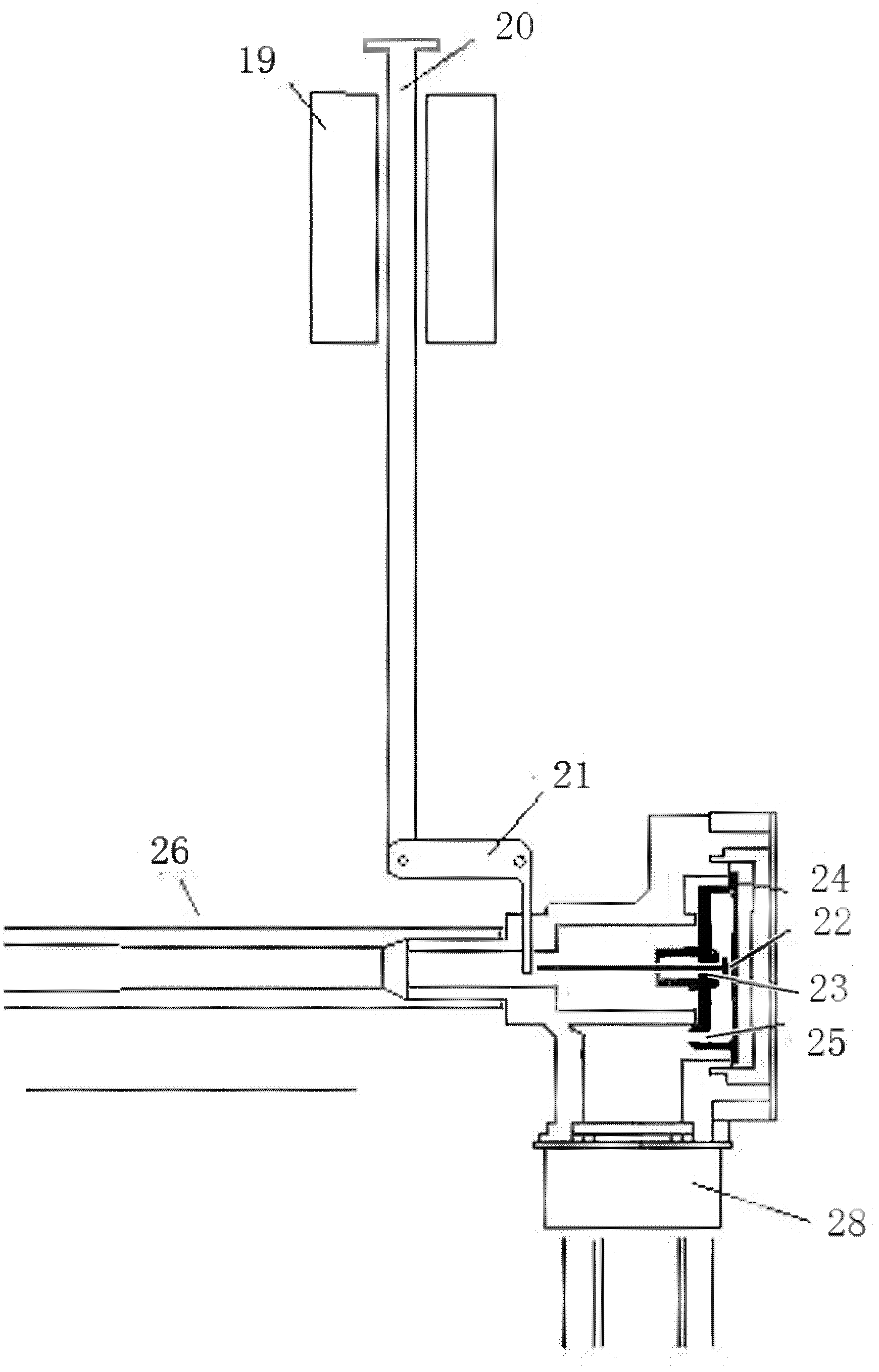

[0030] Such as figure 1 , 2 As shown, the small floating ball flat low-pressure water valve assembly includes a water tank, and the water tank includes a control module for controlling water intake and an execution module for water discharge; the control module includes a water inlet valve 28, a cocking arm 21. Slide the standpipe 20 with the buoy 19 and the leather cup 24. The leather cup 24 is placed at the intersection of the water inlet and the water outlet of the water inlet valve 28. One end surface of the leather cup 24 is attached to the end surface of the water inlet valve 28 outlet. Together, the two ends of the cup 24 are provided with a pressure relief hole 25 communicating with the water inlet of the water inlet valve 28. There is a push rod 22, one end face of the push rod 22 covers the microhole 23, and the other end face is aligned with the warping arm 21 movably connected to the lower end of the standpipe 20;

[0031] Such as image 3 As shown, the executiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com