Concrete pumping extrusion pouring construction method for tunnel secondary lining

A technology of concrete pump and construction method, which is applied in the direction of tunnel lining, tunnel, earthwork drilling and mining, etc. It can solve the problems of reducing the quality of concrete construction, the lack of compactness of secondary lining concrete, and insufficient concrete strength, so as to reduce quality defects and ensure concrete performance. , to ensure the effect of concrete performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

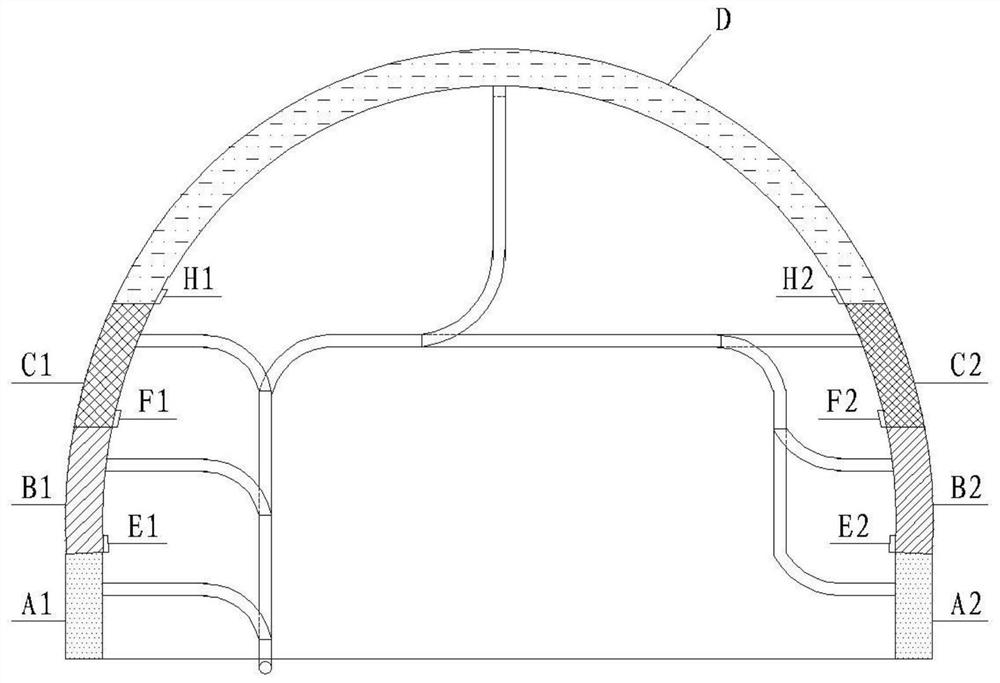

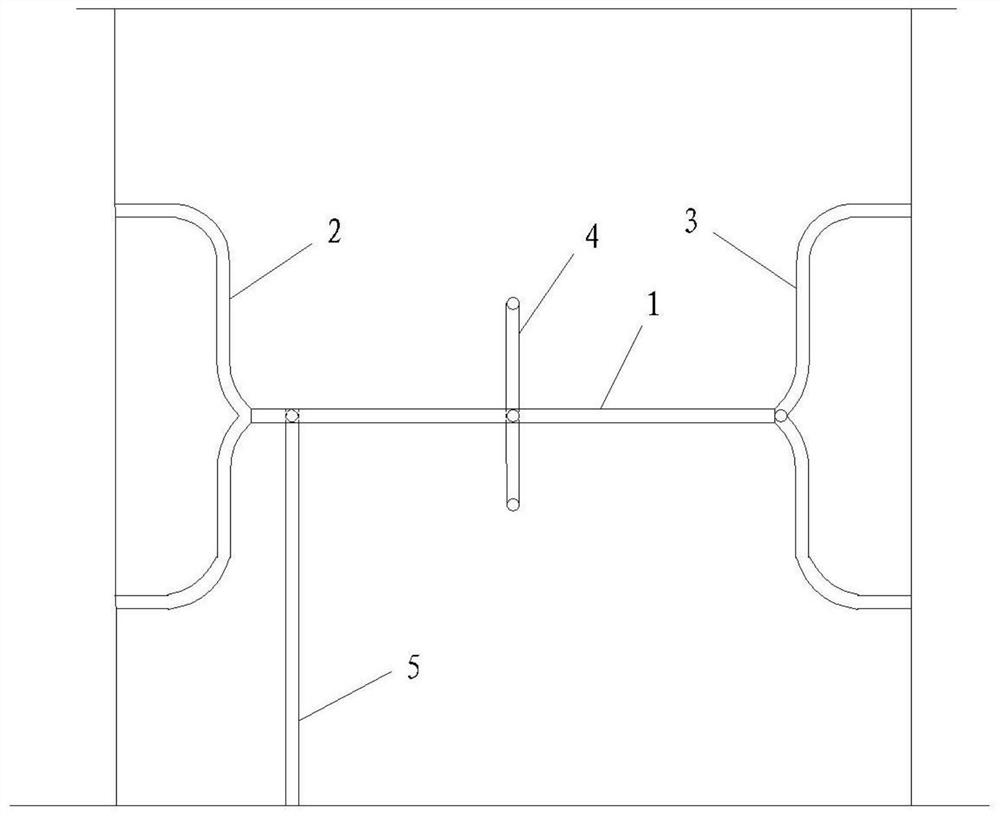

[0025] figure 1 It is a structural schematic diagram of the present invention; figure 2 A schematic diagram of the layout of the pipeline;

[0026] This embodiment provides a construction method for tunnel secondary lining concrete pumping and extrusion pouring, including the following steps:

[0027] S1: Divide the tunnel into an arched pouring area at the top and several layers of bottom pouring areas located on both sides of the tunnel and below the arched pouring area. The pouring area of each layer is approximately symmetrically distributed on both sides of the tunnel; the approximate symmetrical distribution means The pouring area of each layer is symmetrically distributed along the central axis of the tunnel and a certain error is allowed;

[0028] S2: Concrete is poured in the pouring area of each layer through the concrete delivery pump sequentially from bottom to top.

[0029] During the pouring process, the second lining trolley and the concrete delivery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com