Guiding device of winery condenser

A diversion device and condenser technology, applied in the field of brewing, can solve the problems of noise pollution, less recycling, loud noise, etc., and achieve the effect of reducing noise, weakening noise, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

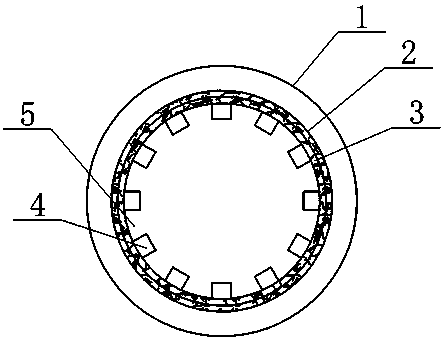

[0014] like figure 1 Shown: the present invention provides a kind of distillery condenser deflector, comprises the steel deflector pipe 1 that is connected with condenser outlet, is connected with the soundproof pipe 2 of hollow structure on the inner wall of described deflector pipe 1, in the hollow At least two layers of sound insulation felt 3 are arranged in the pipe wall of the sound insulation pipe 2 of the structure. The sound insulation felt 3 is made of rubber, polymer materials, etc. as the main raw materials. In order to increase the density of the sound insulation felt, so as to increase the sound insulation As a result, fillers can also be added to the sound insulation felt 3, and the fillers can be metal powder, quartz powder, heavy calcium, etc., and a plurality of ribs 4 with a square cross section are arranged on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com