External wall insulation structure through foaming cement board and construction method thereof

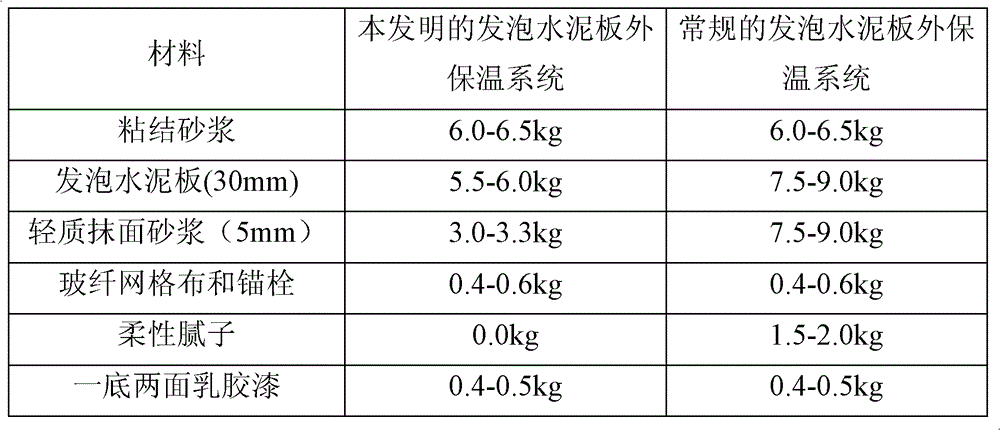

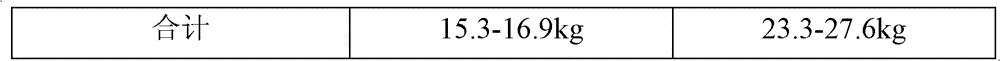

A technology for thermal insulation of foamed cement boards and exterior walls, applied in thermal insulation, building components, climate change adaptation, etc., can solve problems such as easy cracking of thermal insulation structures, achieve the effects of reducing cracking hidden dangers, improving stability, and reducing temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical means realized by the utility model, creation features, purpose and effect easy to be understood, the utility model is further elaborated below.

[0049] The raw materials used in the examples are all industrial products, which can be purchased through commercial channels, and the tools and equipment used to implement the present invention are all common in the construction and painting industries. Among them, the foamed cement board is produced by Nantong Yanyi Coating Technology Co., Ltd., the anchor bolt is a German EJOT brand plastic expansion anchor bolt, the lightweight plastering mortar is produced by Shanghai Tianbu Construction Technology Co., Ltd., and the glass fiber mesh The grid cloth is produced by Xiangfan Huierjie Glass Fiber Co., Ltd., and the sealing primer and topcoat are produced by Kansai Paint Co., Ltd. of Japan.

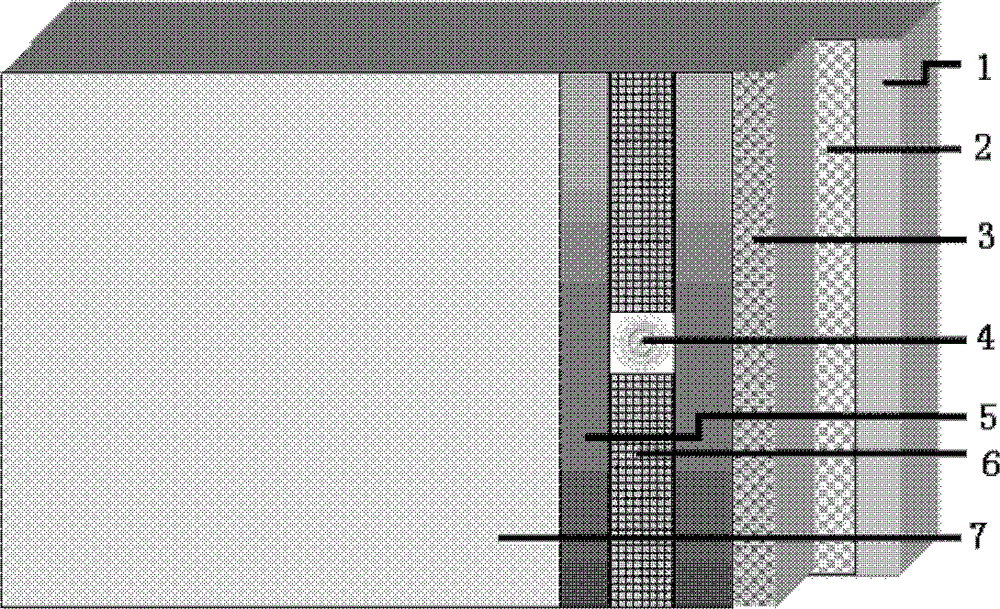

[0050] see figure 1 The thermal insulation structure of the external wall of the foamed cement board is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com