Braking disc for railway vehicles

A technology for rail vehicles and brake discs, applied in the direction of brake discs, etc., can solve the problems of safety accidents, poor heat dissipation effect of ductile iron, long braking distance, etc. The effect of moderate moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

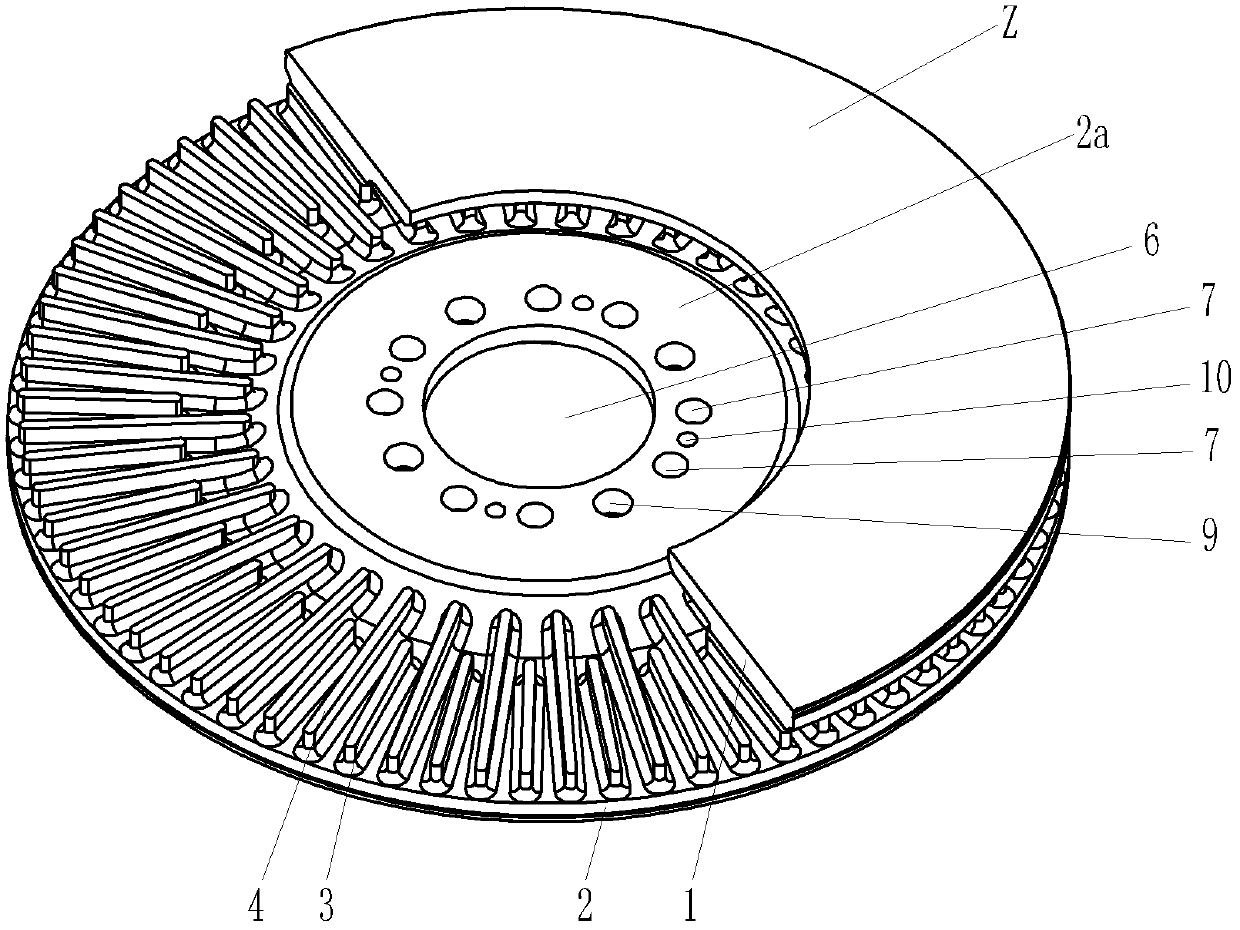

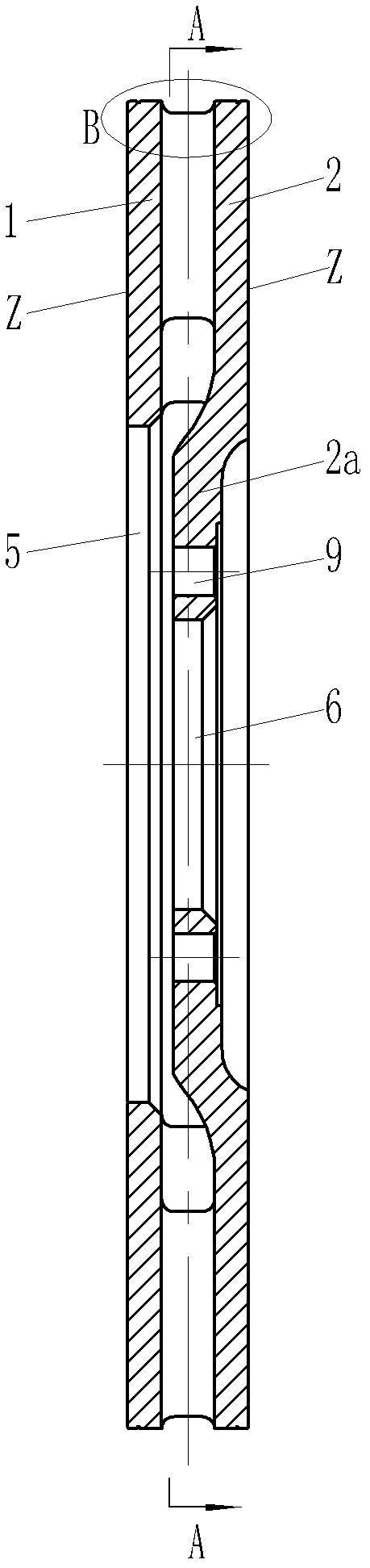

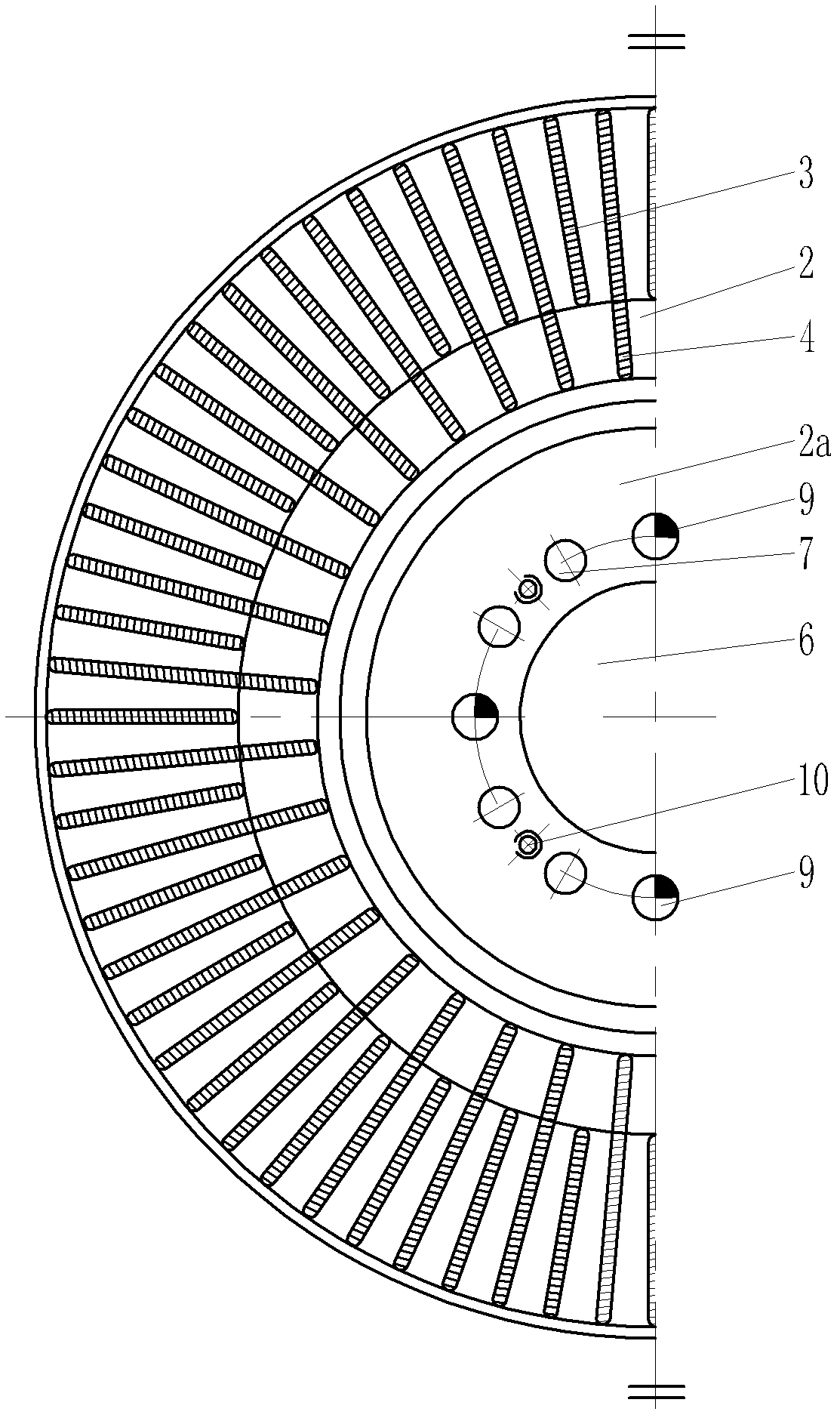

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0026] Such as figure 1 , 2 , 3 and 4, the brake disc is made of vermicular graphite cast iron, in terms of weight percentage, the chemical composition of the brake disc is:

[0027] Carbon: 3.45% to 3.77%, silicon: 1.86% to 2.25%, manganese: 0.5% to 0.8%, sulfur: ≤0.02%, phosphorus: ≤0.05%, the rest is iron, and the vermicular rate of the vermicular graphite cast iron is ≥ 60%.

[0028] The brake disc is composed of a left disc body 1, a right disc body 2, a first radial connecting rib 3 and a second radial connecting rib 4, wherein the left disc body 1 and the right disc body 2 have the same diameter, and the left disc body The left surface of 1 and the right surface of the right disc body 2 are braking working surfaces Z, and the roughness of these two braking working surfaces Z is both 1.6 mm to 3.2 mm, generally preferably 1.6 mm. A circular groove 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com