Hydraulic self-driven double-gate disc gas gate valve

A double gate, hydraulic technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problem that the speed limit of the valve opening and closing speed electric device can not be increased quickly, the double-plate gas gate valve is large in size and takes up a lot of space, etc. problems, to achieve the effect of novel appearance structure, light weight, and lower height of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

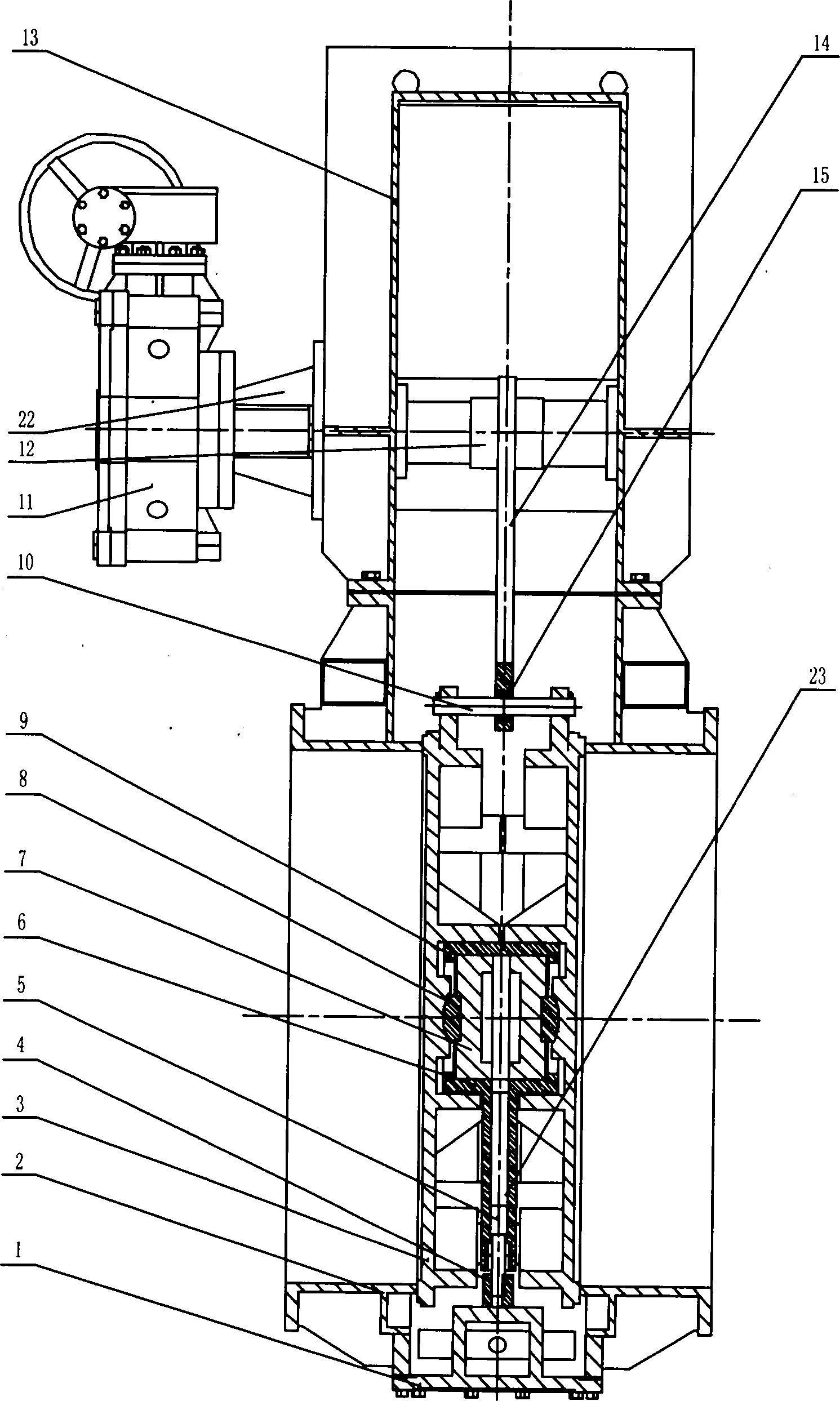

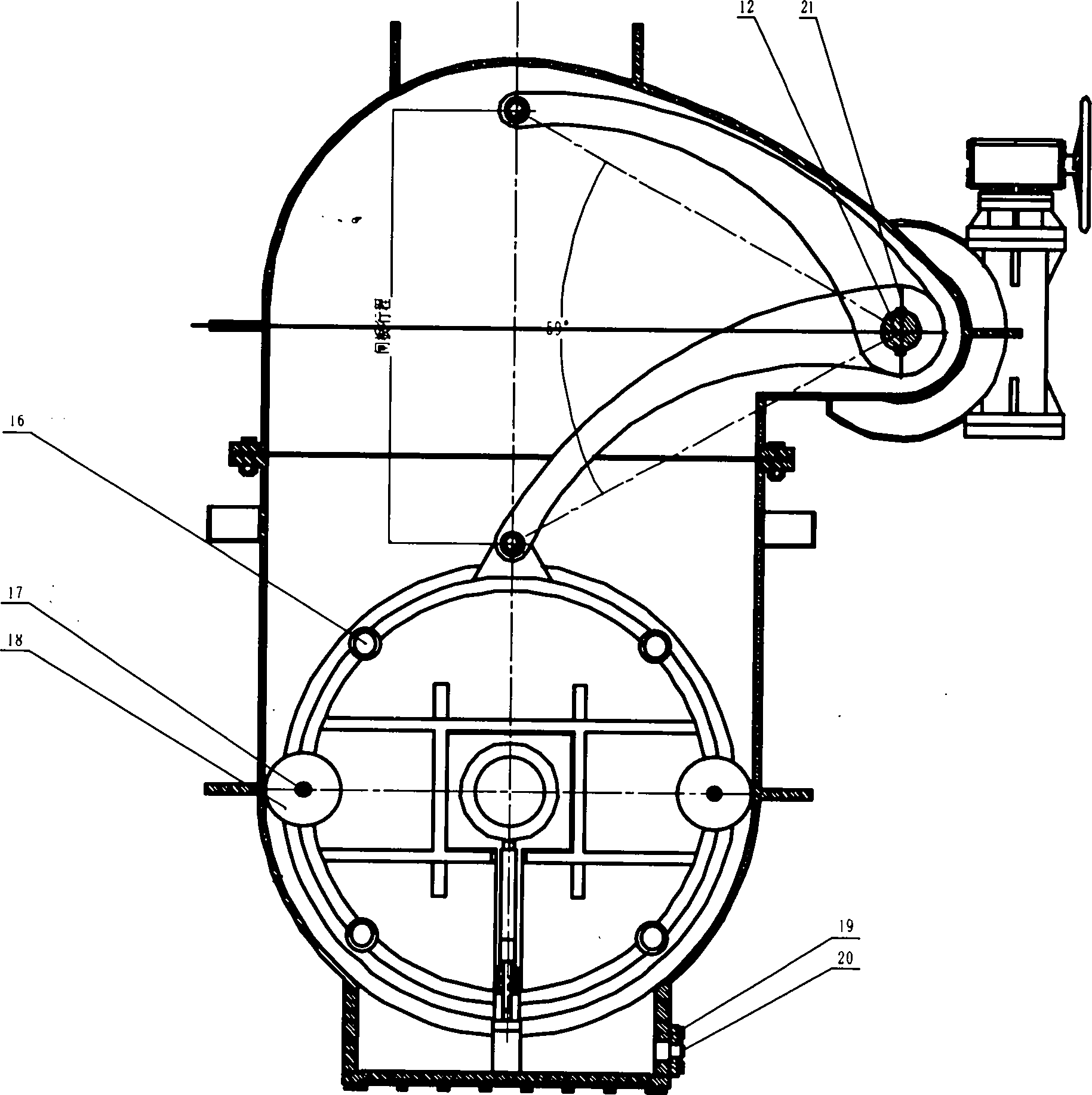

[0016] Implementation 1. Realization of the opening and closing mechanism

[0017] In the figure, the valve stem 12 is connected with the driving device 11, and the valve stem 12 and the rocker arm 14 are all connected by keys. The rocker arm 14 is connected with the gate plate 3 through the connecting shaft 10 . The gate 3 realizes the vertical movement of the gate 3 in the valve body 2 through the roller shaft 17 and the roller 18 . The valve rod 12 is driven by the driving device 11 to rotate at a fixed axis, so that the rocker arm 14 rotates, and drives the connecting shaft 10 and the gate plate 3 to move vertically. The roller 18 installed on the gate 3 rolls on the inner steel plate of the valve body 2, so that the gate moves in the vertical direction and partially rotates during the opening and closing process. This movement can make the sealing surfaces of the body and the plate get mutual Grinding to ensure that the dirt on the sealing surface is removed. In the ac...

Embodiment 2

[0018] Implementation 2. Realization of brake tightening mechanism

[0019] After the valve is closed in place, the adjustment pad 4 is pressed on the base 1 under the action of the gravity of the gate plate 3, so that the small piston 5 generates pressure on the hydraulic oil in the cylinder 6, and then the hydraulic oil generates pressure. According to the internal pressure of the liquid is equal everywhere In principle, the hydraulic oil in the oil cylinder 6 generates an outward thrust on the large piston 7, and the thrust is transmitted to the gate 3 through the top center 8, and then a sealing force is generated between the gate sealing surface and the valve body sealing surface to realize the protection against the medium. seal.

[0020] When the valve is opened, the rocker arm 14 swings upward under the drive of the driving device 11, so that the adjustment pad 4 is out of contact with the base 1, and at the same time, under the action of the small spring 23 in the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com