Light path deflecting optical fiber strain sensor based on optical fiber LP21 mode

An optical fiber strain and steering type technology, which is applied in the direction of instruments, optical devices, and measuring devices, can solve the problems of complex structure of optical fiber torsion sensors, inability to measure torsional strain, and poor anti-interference performance, so as to facilitate miniaturization and large-scale production The effect of laying, spot shape stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

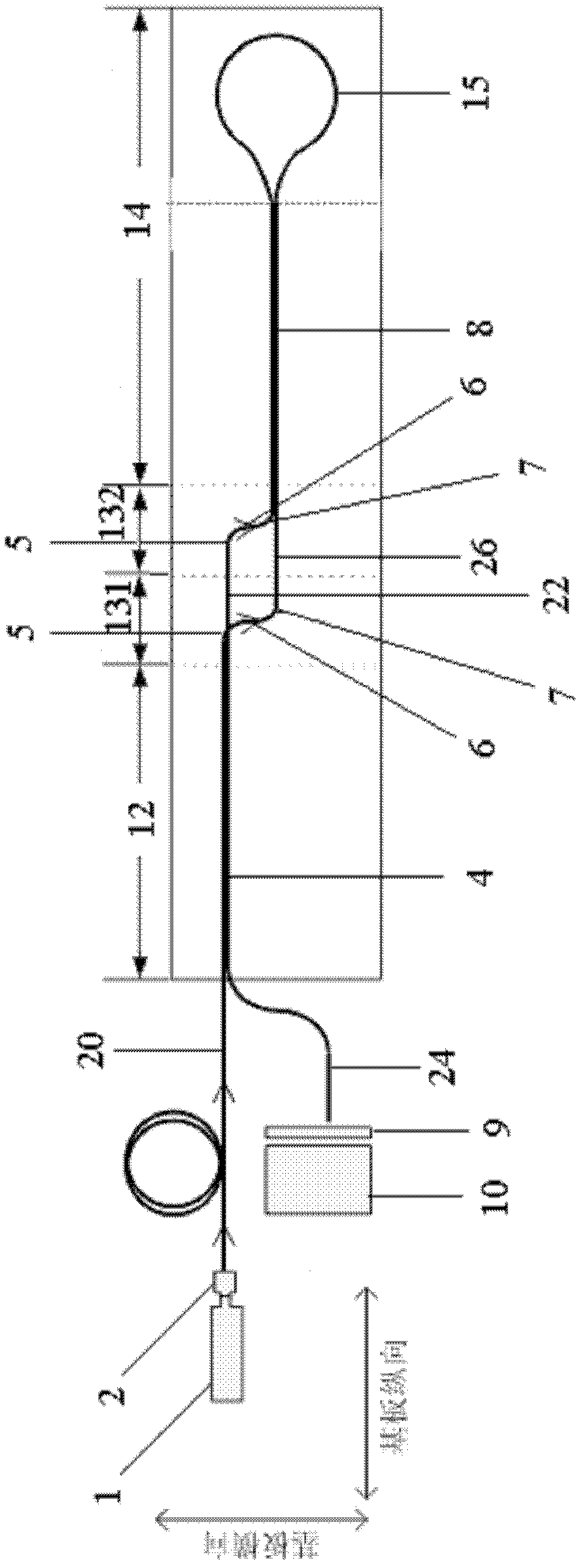

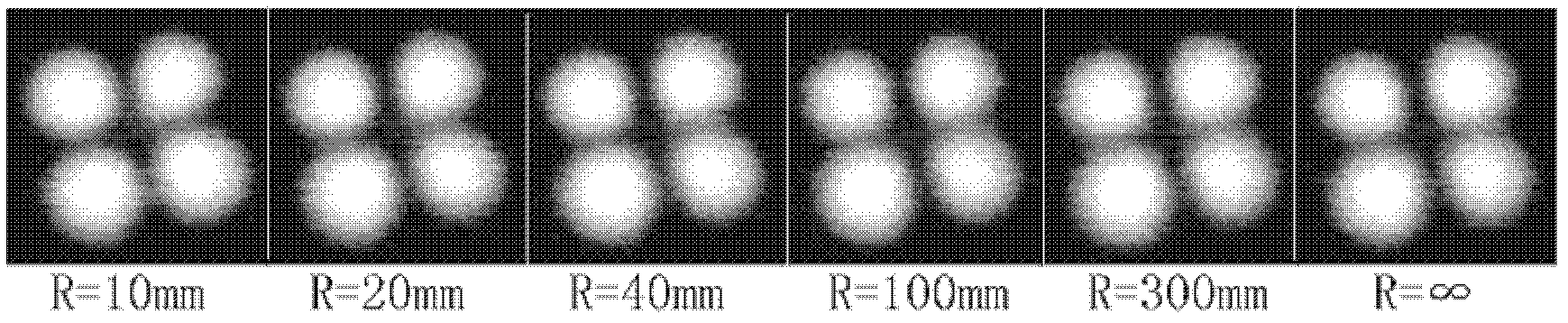

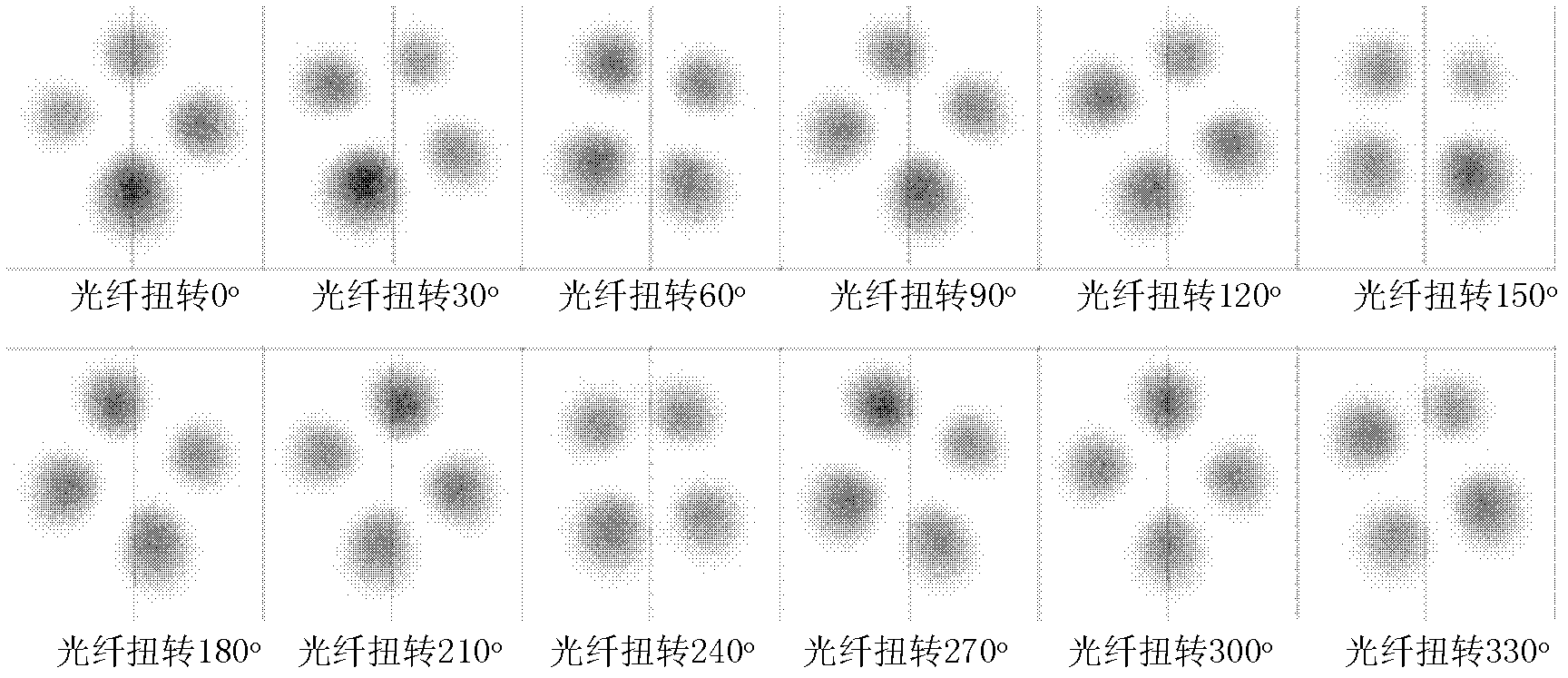

[0032] Such as figure 1 Fiber-based LP shown 21 The optical fiber strain sensor of the present invention comprises an optical fiber light spot generation and sensing device, an optical attenuation sheet 9, a light spot detector 10, a computer, and a substrate. The optical fiber spot generation and sensing device includes a light source 1, a mode selector 2 and a fiber-based LP 21mode optical fiber, the light source 1 is connected to the input end of the mode selector 2, and the output end of the mode selector 2 is connected to the input end of the optical fiber. The optical fiber includes an incident part 4, a sensing part, and an outgoing part 8. The output end of the mode selector 2 is connected to the incident part 4 of the optical fiber, and the sensing part includes a sensing part connected to the incident part 4 of the optical fiber. Part of the input end 5, the sensing portion output end 7 connected to the fiber optic output portion 8, the sensing portion input end 5,...

Embodiment 2

[0050] Such as Figure 5 As shown, the optical fiber strain sensor described in Embodiment 1 can be used together in multiple groups; at this time, the substrate is divided into N+2 parts, and N is the number of optical fiber spot generation and sensing devices fixed on the substrate. The number of sensing parts of the optical fiber is fixed in one-to-one correspondence with the sensing parts of the optical fiber. In this embodiment, multiple groups of optical fiber strain sensors share one light spot detector 10 .

[0051] The measurement method of the present invention is composed of the following steps: 1. Utilize the laser transmitter to generate a beam of laser light and enter the strain sensor through the mode selector 2; 21 The transmission characteristics of the mode process the optical signal; 3. After the optical signal passing through the sensor is processed, it enters the signal processing device, and finally realizes the measurement of the torsion or space curvat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com