Detection device and detection method for wear loss of shield machine cutter

A shield machine tool and detection device technology, which is applied in the direction of measuring devices, ultrasonic/sonic waves/infrasonic waves, instruments, etc., can solve the problems of increased difficulty of electronic components, difficulty of shield tunneling, and difficulty in guaranteeing the cutting diameter of the cutterhead, etc. , to achieve the effect of convenient use, high reliability and strong real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

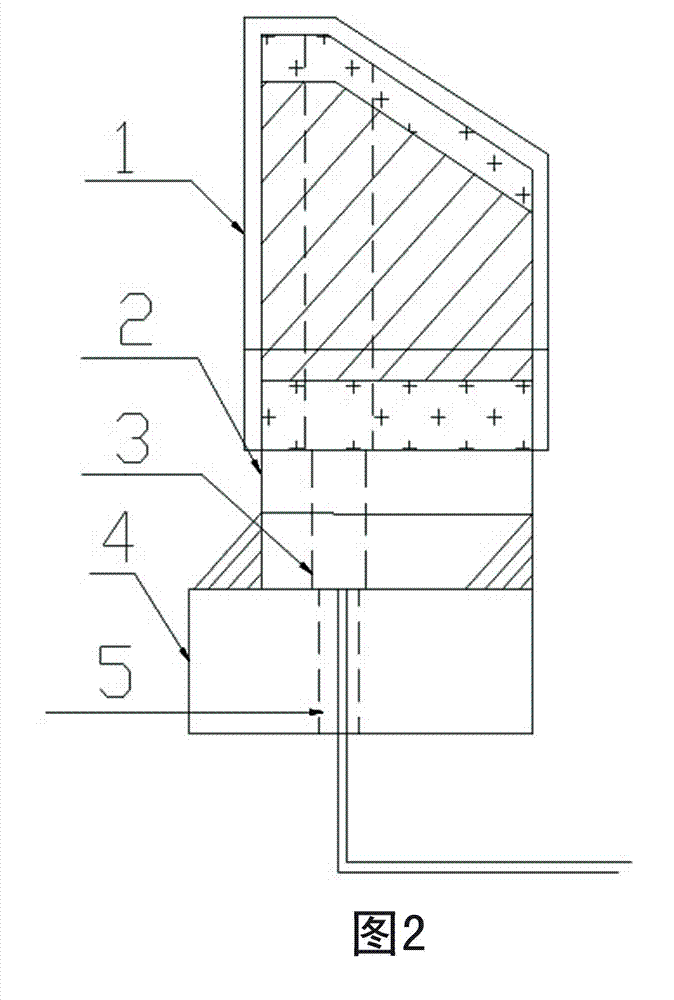

[0028] The present invention utilizes a detection probe installed in the leading tooth cutter on the outer periphery of the shield machine to detect the alloy height of the surrounding leading tooth cutter to reflect the wear amount of the peripheral tooth cutter.

[0029] The invention overcomes the defect that the hydraulic limit detection method can only give an alarm when the cutter is worn to a certain height by detecting the wear amount of the outer peripheral tooth cutter instead of the scraper, and is a real-time continuous detection device .

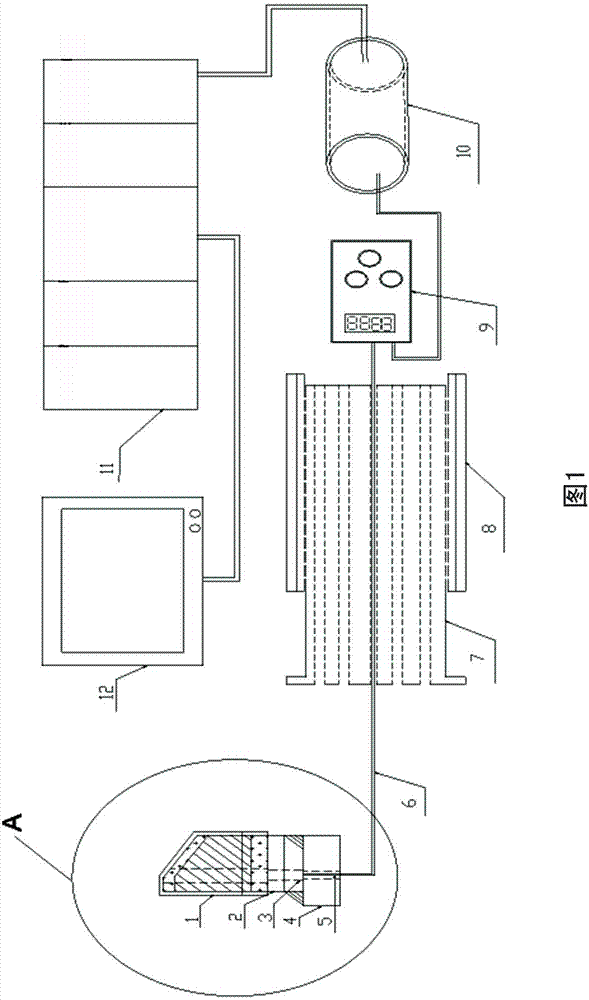

[0030] see figure 1 , a detection device for the amount of tool wear of a shield machine, a detection probe 3 connected to the input end of a detector 9 through a data line 6 is provided in the outer peripheral too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com