Vehicle-mounted laser measuring method for mining area subsidence

A technology of laser measurement and laser measurement system, which is applied in the field of vehicle-mounted laser measurement of mining area subsidence, can solve the problems of high flight cost, inability to meet the needs of subsidence monitoring work, and long field observation operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

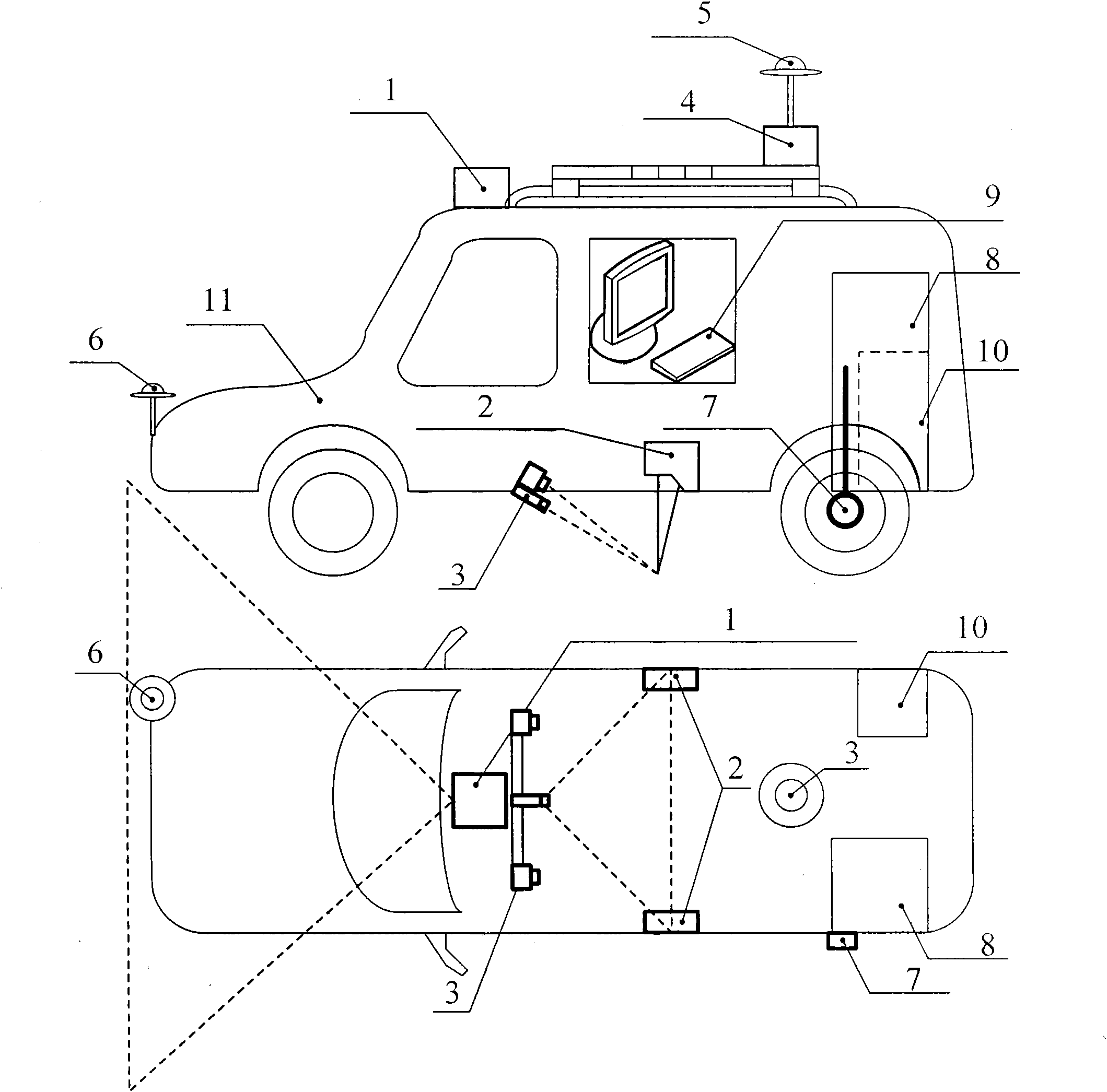

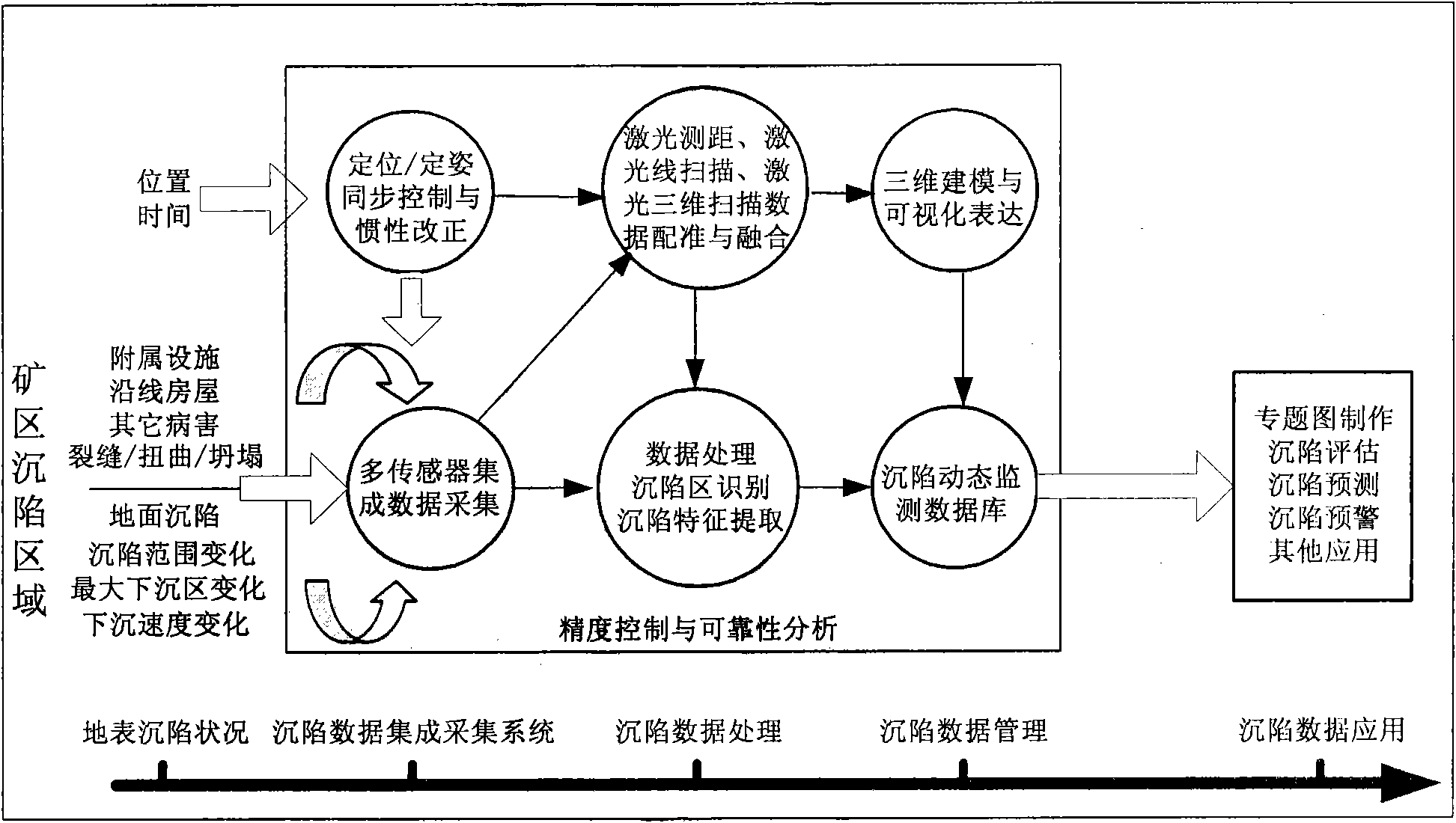

Embodiment Construction

[0078] Using the vehicle-mounted laser measurement method for mining subsidence, the difference between the two measurement results of the elevation information of the surface point in the subsidence area of the mining area can be calculated, and the subsidence amount can be accurately calculated to achieve high efficiency (speed 0-60Km / h), high resolution (subsidence The data sampling interval is less than 1m, and the spatial positioning accuracy of subsidence data is better than 5m), large-scale (laser measurement range can cover 80m around the driving route), and high-precision (subsidence monitoring accuracy reaches 1cm) automatic monitoring of mine subsidence. Using the vehicle-mounted laser measurement method for mining area subsidence, the surface elevation difference is detected based on time series, the subsidence area is automatically identified, and the subsidence features are extracted; then a 3D visualization model of the mining area subsidence is established, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com