Industrial robot space grid precision compensation method based on neural network

An industrial robot and neural network technology, applied in the field of industrial robot calibration, can solve the problems of large measurement workload, large calculation amount, and unsatisfactory effect, so as to reduce the measurement workload, improve the absolute positioning accuracy, and the calculation process is simple and fast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

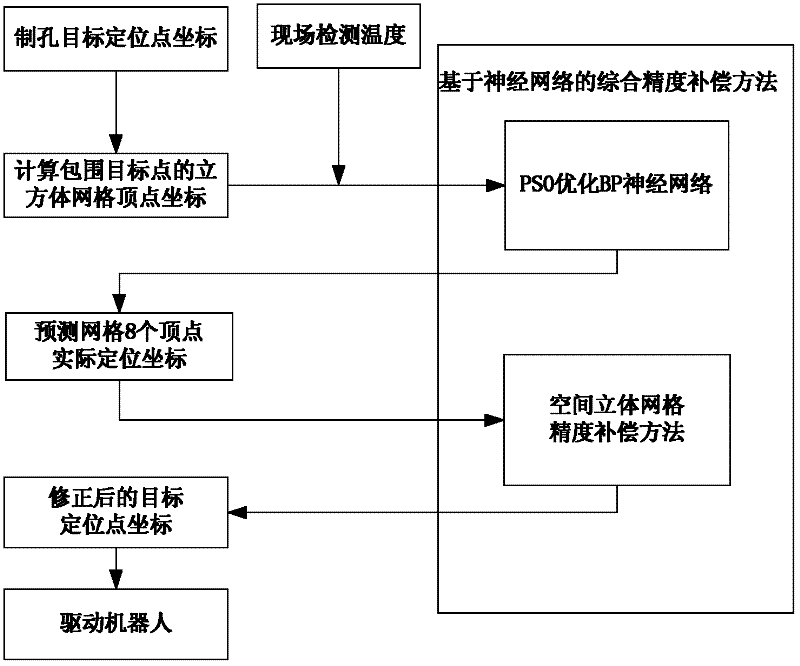

[0028] The steps of the industrial robot space grid precision compensation method based on particle swarm optimization neural network in the present invention are as follows:

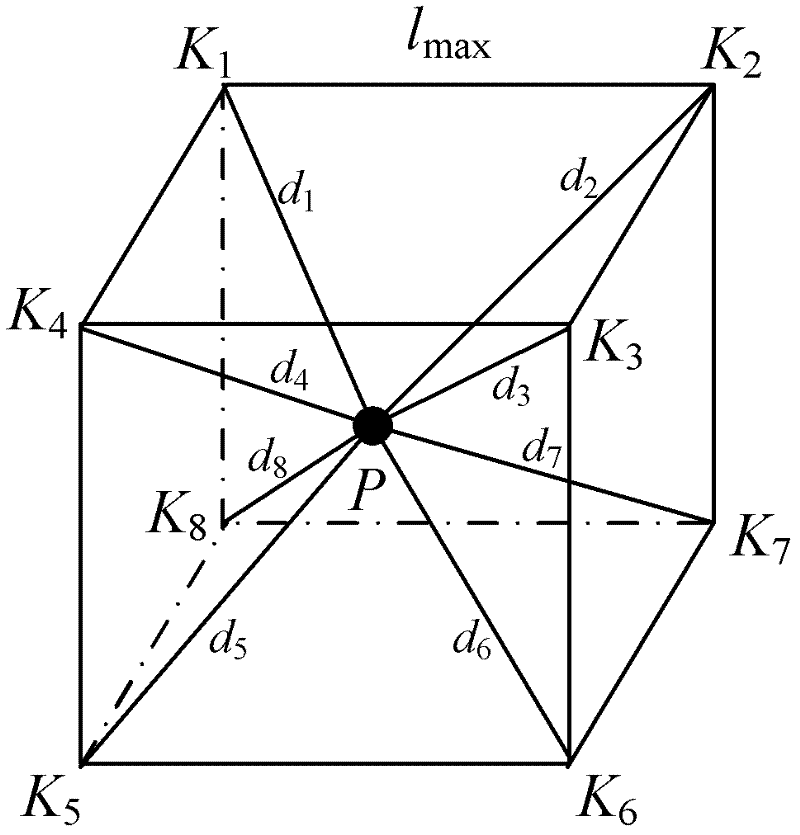

[0029] Step 1: within the envelope of the industrial robot, the area to be processed in the envelope space of the robot is divided into a series of cubic grids according to a certain step size;

[0030] Step 2: Measure and establish the base coordinate system of the robot through the laser tracker, use the theoretical coordinates of the eight vertices of each cube grid divided in step 1 to control the robot for positioning at several different temperature levels, and track with the laser The instrument measures and records the actual positioning coordinates;

[0031] The steps to establish the association between the laser tracker and the robot base coordinate system are:

[0032] 1) The spherical fixed reflector SMR is fixed on the TCP of the end effector, and the position (angle) of the A2 to A6 axes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com