Water pressure loading control system and loading method used in fluid-solid coupling model test

A control system, coupled model technology, applied in the direction of using stable tension/pressure to test the strength of materials, instruments, measuring devices, etc. Achieve effective monitoring and control, solve water leakage, and have a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

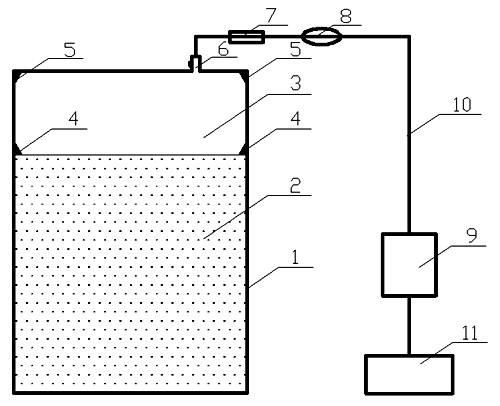

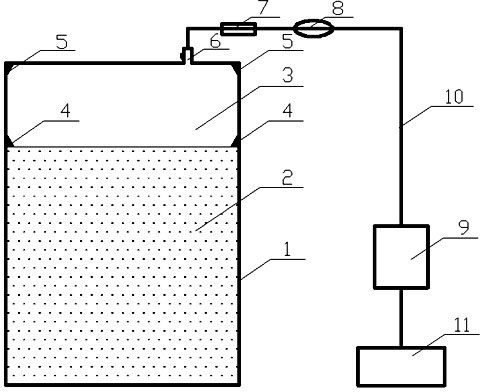

[0027] figure 1 Among them, a hydraulic loading control system used in fluid-solid coupling model tests, including a test bench 1, the test bench 1 adopts a sealed design, and several layers of similar materials 2 are laid inside, and the interior of the test bench, similar materials There is a water tank 3 for hydraulic loading on the top of the test bench. The top of the test bench is provided with a water injection hole communicating with the water tank 3. The water injection hole is connected with the water source 11 outside the test bench 1 through a water pipe 10, and the water injection hole is connected to the water source 11. A control system for controlling water injection is provided between them.

[0028] The test bench 1 is a rigid sealed bench. The exterior of the test bench 1 adopts a high-strength rigid structure frame, and the interior...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com