A Continuous Zoom Fresnel Lens

A Fresnel wave zone and lens technology, which is applied in the direction of lenses, optics, instruments, etc., can solve the problems of not being able to use glasses, and the aperture cannot be enlarged, and achieve the effect of continuous zooming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

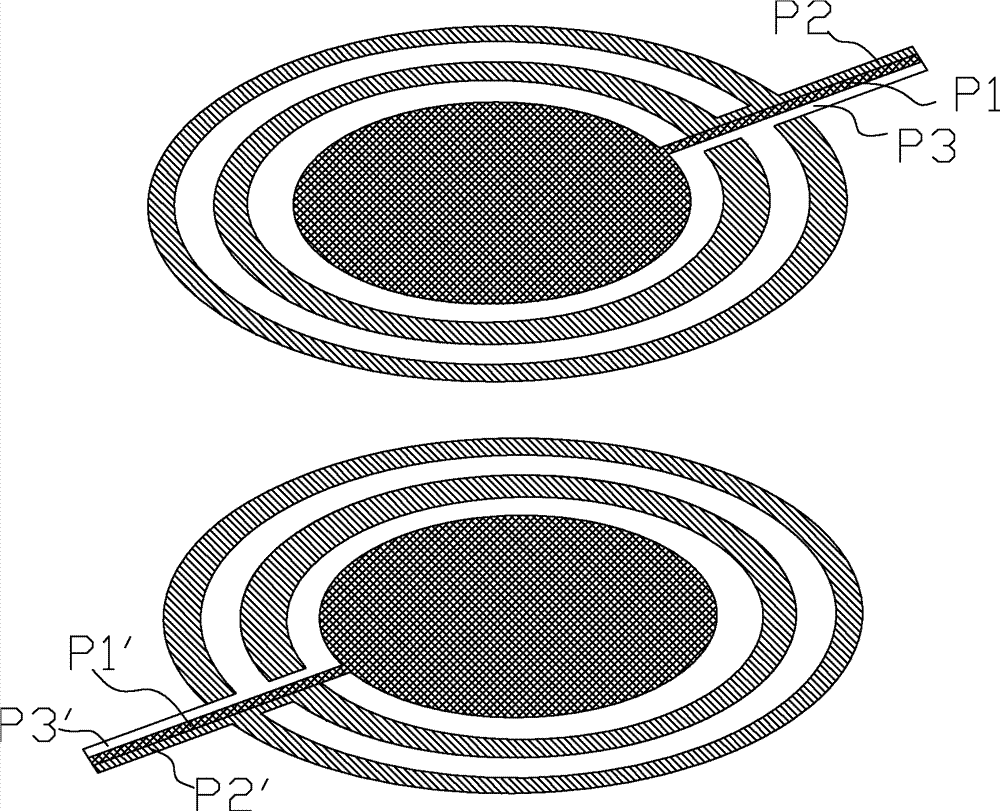

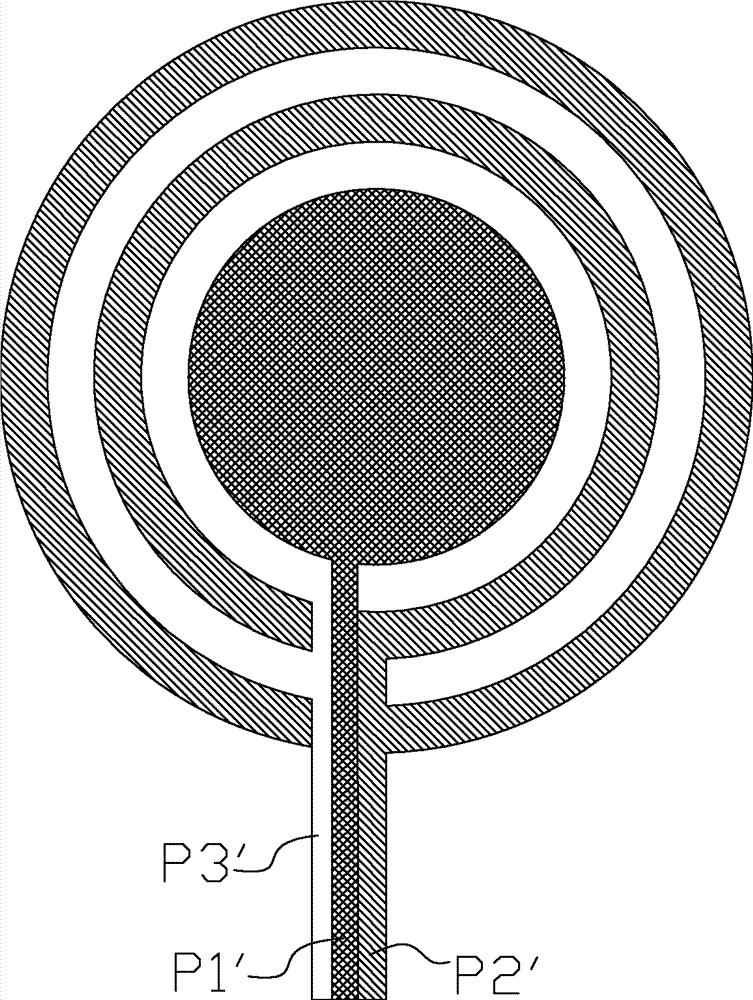

[0037] The basic idea of the continuous zoom Fresnel lens of the present invention is to design a double-band or triple-band pattern on the plane substrate electrode, and control the position driving voltage of the double-band or triple-band independently or in association to change the refractive index of the liquid crystal to realize continuous zooming. .

[0038] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

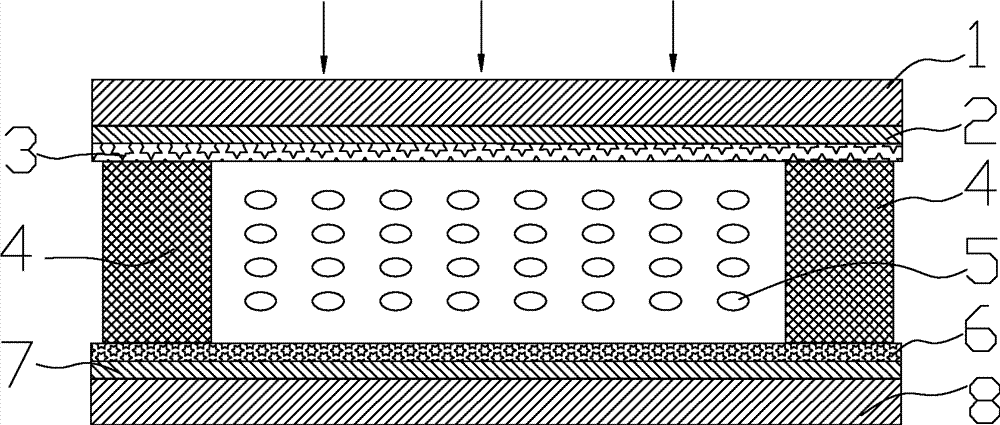

[0039] see figure 1 , represents a longitudinal section of the continuous zoom Fresnel lens (hereinafter referred to as the lens) of the present invention along the light incident direction. The basic structure of the lens is similar to that of an ordinary liquid crystal cell, and specifically includes an upper plane substrate 1, an upper plane substrate electrode 2, an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com