Power supply control device for polycrystalline silicon reduction furnace

A technology of power control device and reduction furnace, which is applied in electrical program control, program control in sequence/logic controller, silicon and other directions, can solve the problems of high PLC cost, inconsistent resistance characteristics, and reduced yield, etc., and achieve system composition. Simple, solve the imbalance problem, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with the accompanying drawings and specific embodiments.

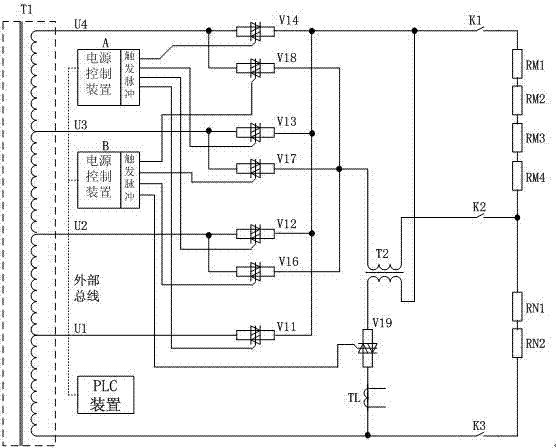

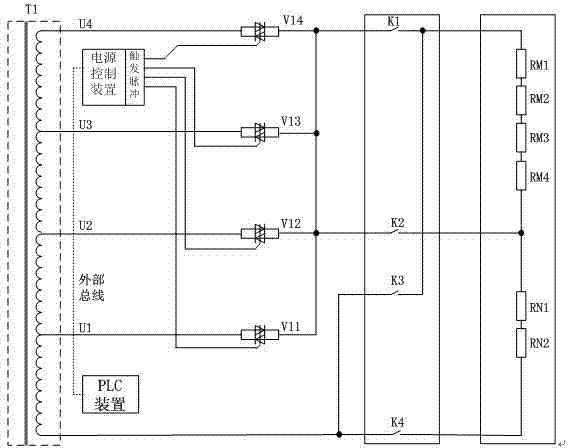

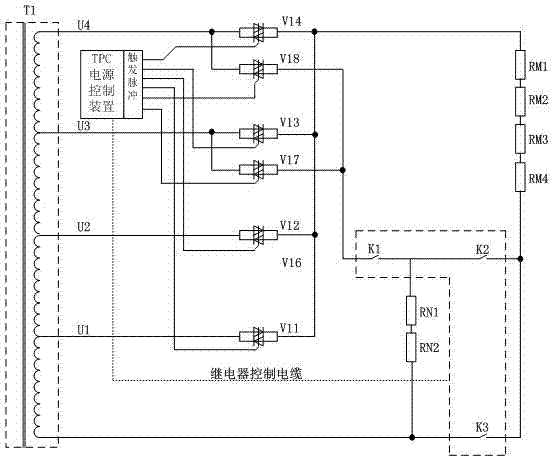

[0025] In order to solve the unbalanced current problem of parallel breakdown of silicon rods and reduce the complexity of the entire system, the present invention firstly controls the breakdown of two groups of silicon rod circuits separately through thyristors by the control device, and then uses the control device to connect the two groups of silicon rods through relays. String to a group of heating; complete temperature acquisition and control strategy in a single control device, no longer use PLC. The control device includes voltage and current modules, temperature sensing modules, digital filter modules, phase tracking modules, input and output modules, control modules, optical trigger modules, field bus modules, thyristor drive modules, HMI modules. The voltage and current module converts the high voltage and high current on the silicon ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com