Wiring structure for electrically powered two- or three-wheeled vehicle

A wiring structure and technology for tricycles, applied in electric scooters, motor vehicles, motorcycles, etc., can solve the problems of affecting design, too conspicuous wiring, thick wiring, etc., and achieve the effect of suppressing noise interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

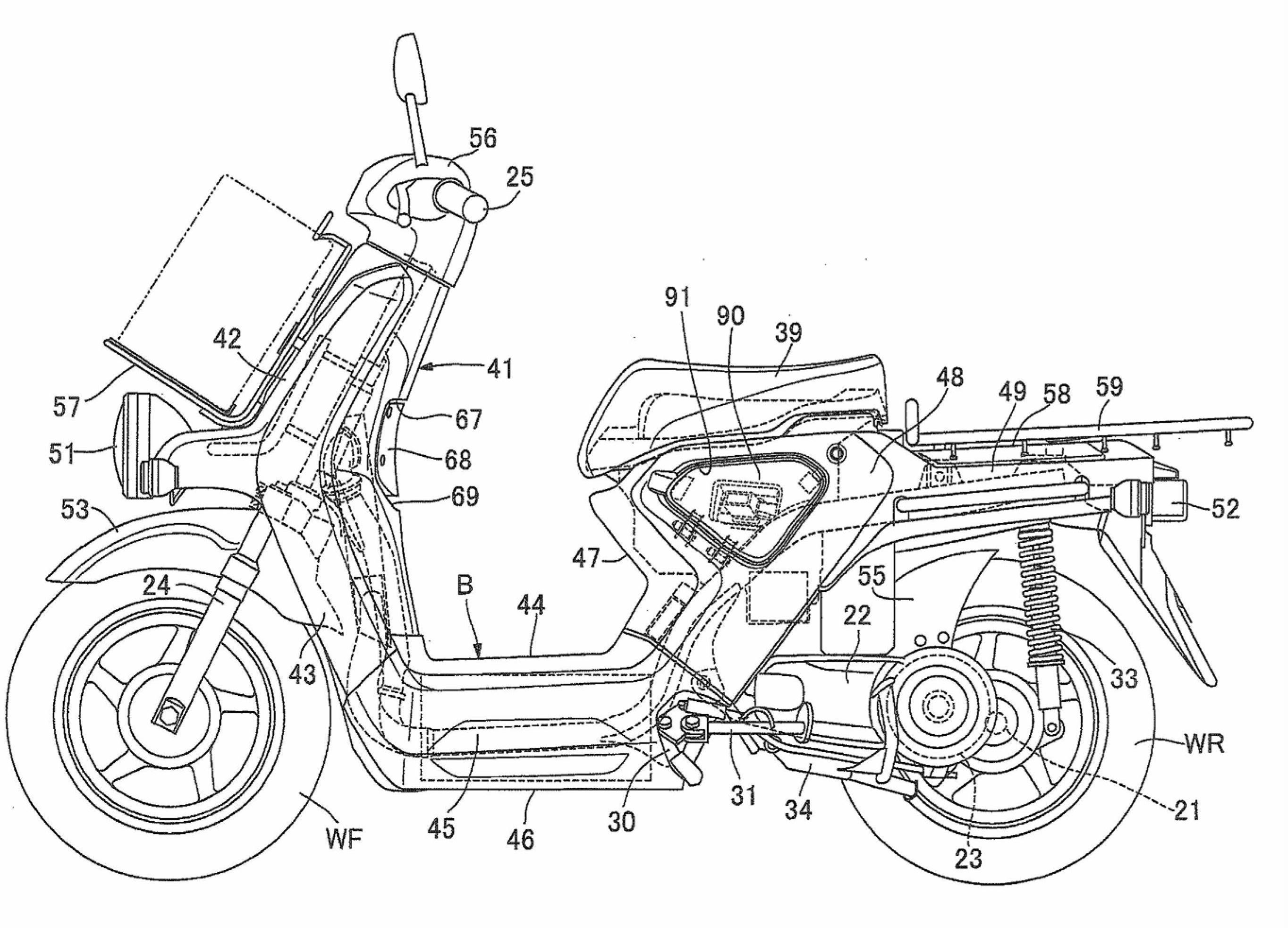

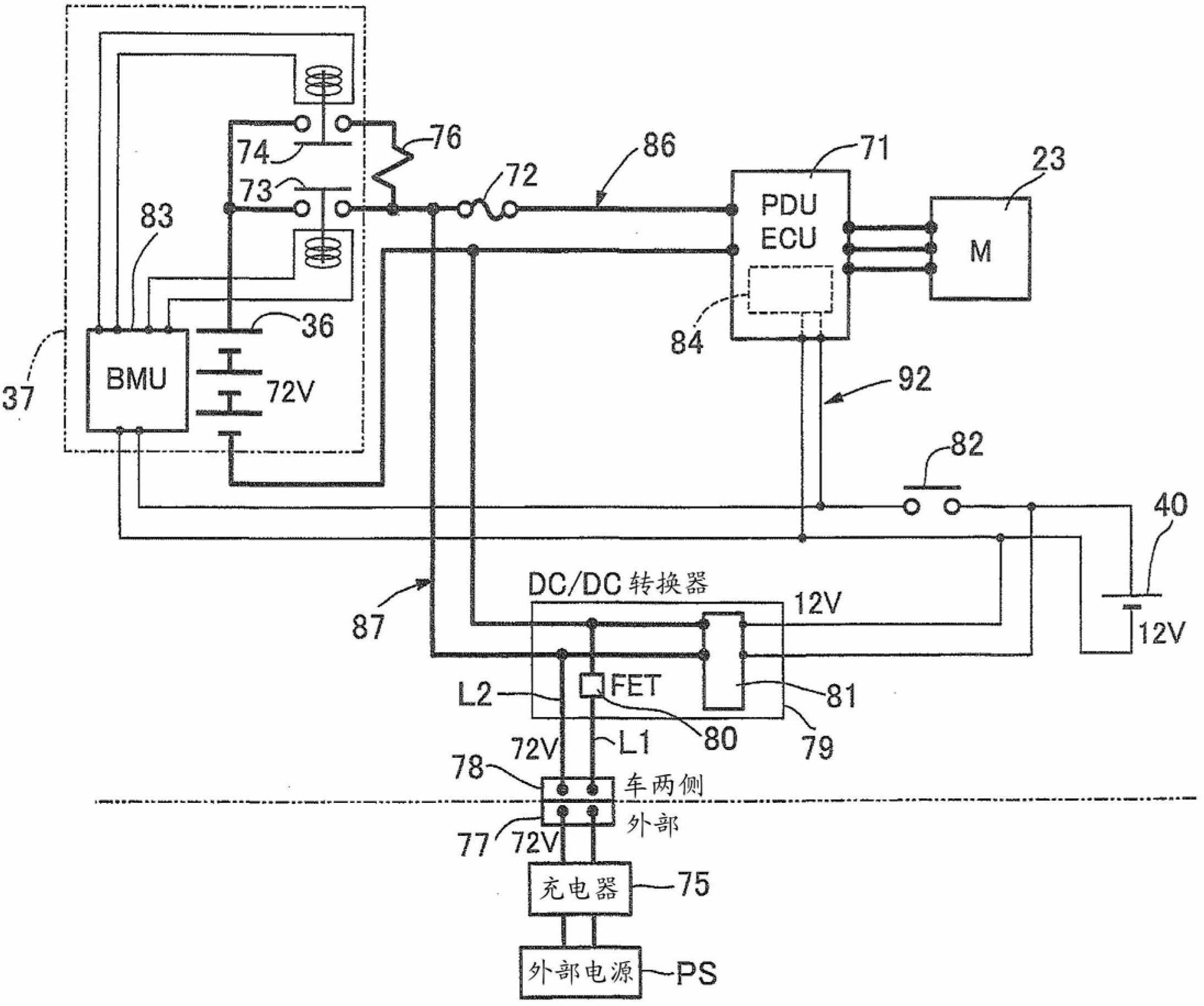

[0048] in reference to Figure 1~Figure 7 When describing Embodiment 1 of the present invention, at first, in figure 1 Among them, the electric two-wheeled vehicle is a scooter-type electric two-wheeled vehicle having pedals 44, and is configured such that the rear wheel WR is driven to rotate by the rotational power output by the electric motor 23 built in the swing arm 22, and the swing arm 22 The arm 22 pivotally supports the axle 21 of the rear wheel WR at the rear.

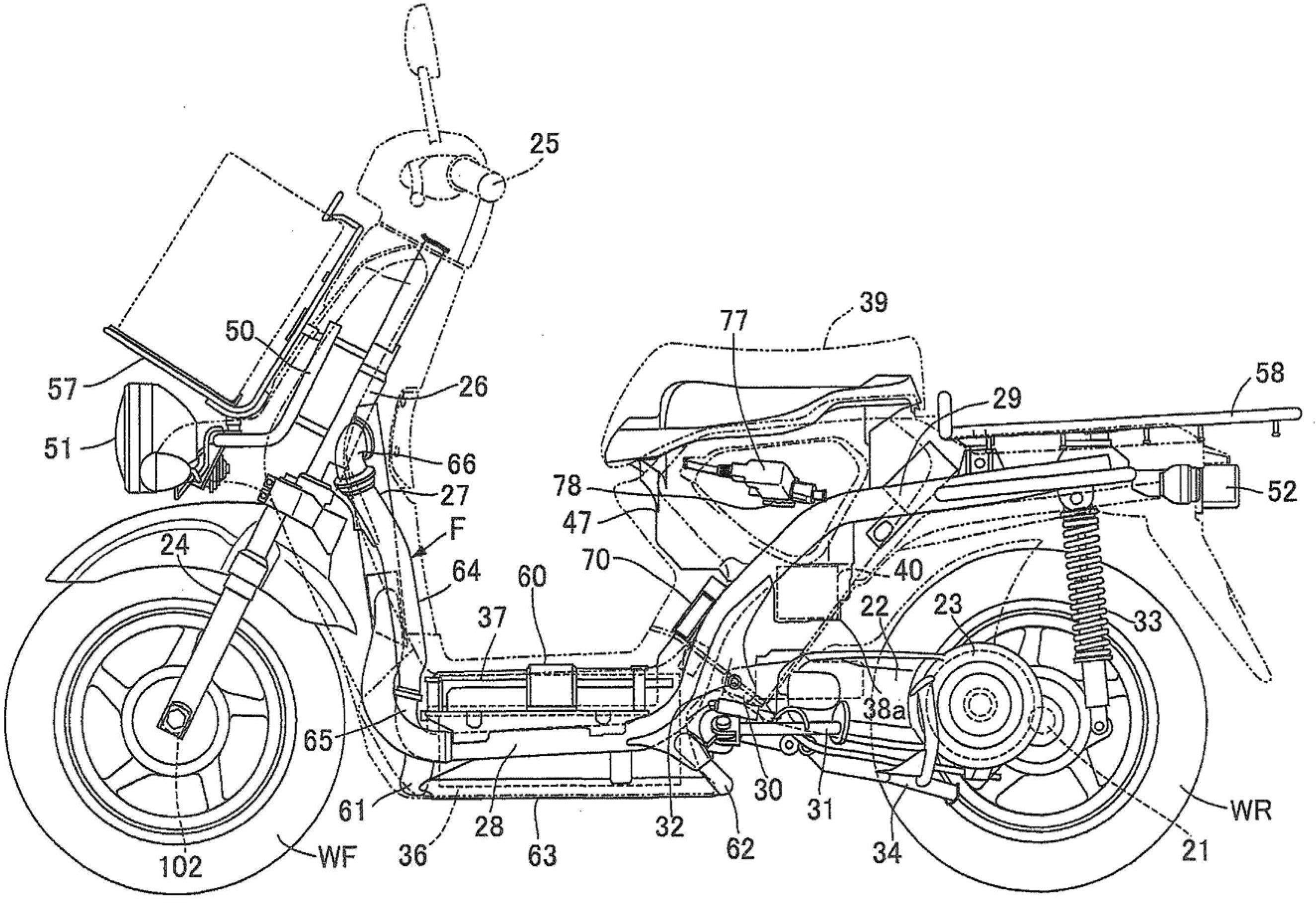

[0049] exist figure 2 Among them, the body frame F of the electric two-wheeled vehicle is provided with: a head pipe 26, which can steerably support the front fork 24 and the steering handle 25, the front fork 24 pivotally supports the front wheel WF, the steering handle 25 and the front fork 24 The lower frame 27 extending from the head pipe 26 to the rear and downward; the left and right pair of chassis 28 connected to the lower part of the down frame 27 and extending backward; and the rear end of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com