High-elastic vibration reduction box structure, manufacturing method and sole with embedded high-elastic vibration reduction box

A high-elasticity, box-body technology, applied in the direction of shoe soles, footwear, clothing, etc., can solve the problems of shortening the service life of air-cushion soles, increasing foot damage, shape deformation, etc., to reduce weight, prevent foot damage, and work longer The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

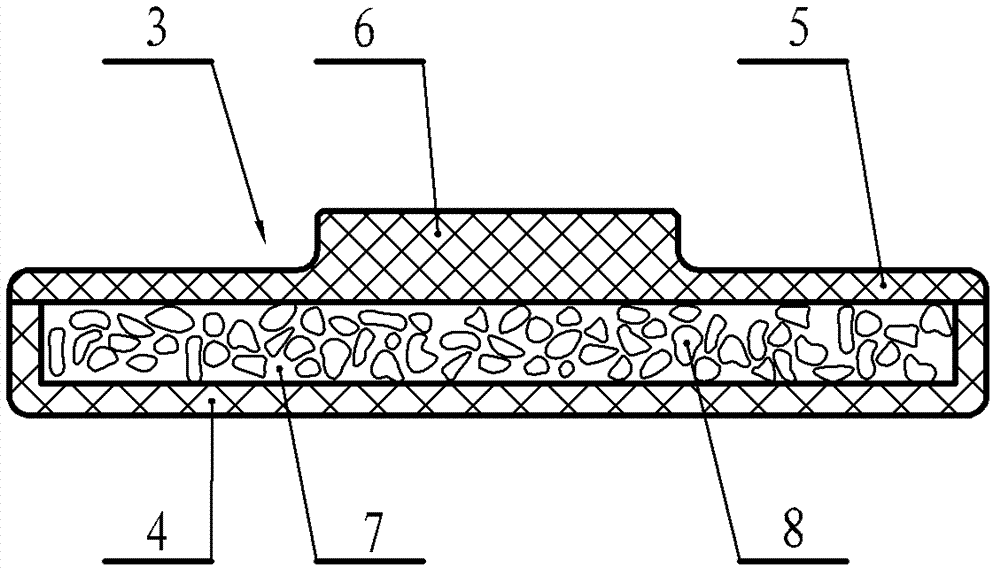

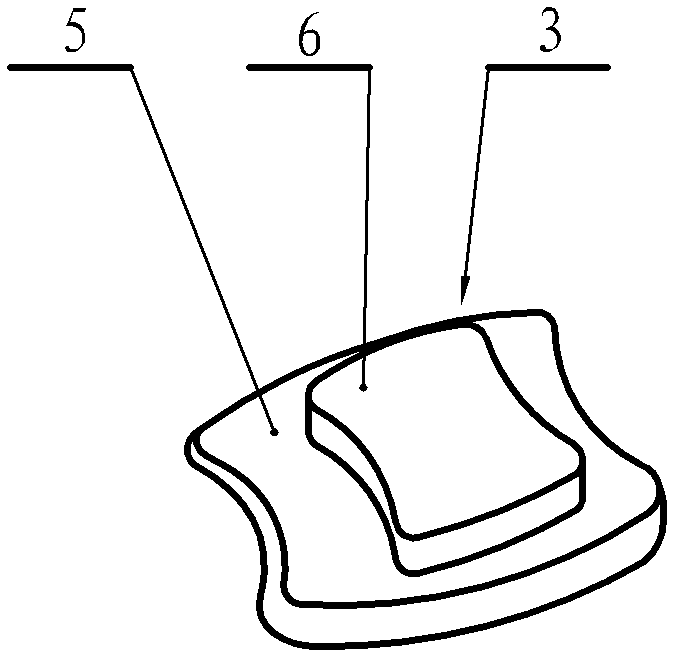

[0033] The schematic diagram of the cross-sectional structure of the high-elastic damping box of the present invention is as follows: figure 1 As shown, the high-elastic damping box 3 includes a high-elastic damping box body 4 and a high-elastic damping box cover 5, the high-elastic damping box body 4 is a barrel-shaped structure with a closed bottom, and the high-elastic damping box cover 5 It is a plate-like structure, and the shape of the high-elastic damping box cover 5 is adapted to the port shape of the high-elastic damping box body 4, and the cavity of the high-elastic damping box body 4 is filled with polyurethane gel evenly mixed with polyurethane particles 8 7. The maximum radial size of the polyurethane particles 8 is smaller than the depth of the cavity of the high elastic damping box body 4, and the high elastic damping box cover 5 is closed and fixedly connected to the port of the high elastic damping box body 4.

[0034] The structure of the high-elastic damping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com