Printing press

A technology of a printing machine and a printing mechanism, applied in the field of printing machines for printing labels, can solve the problems of expensive processing steps and high technical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

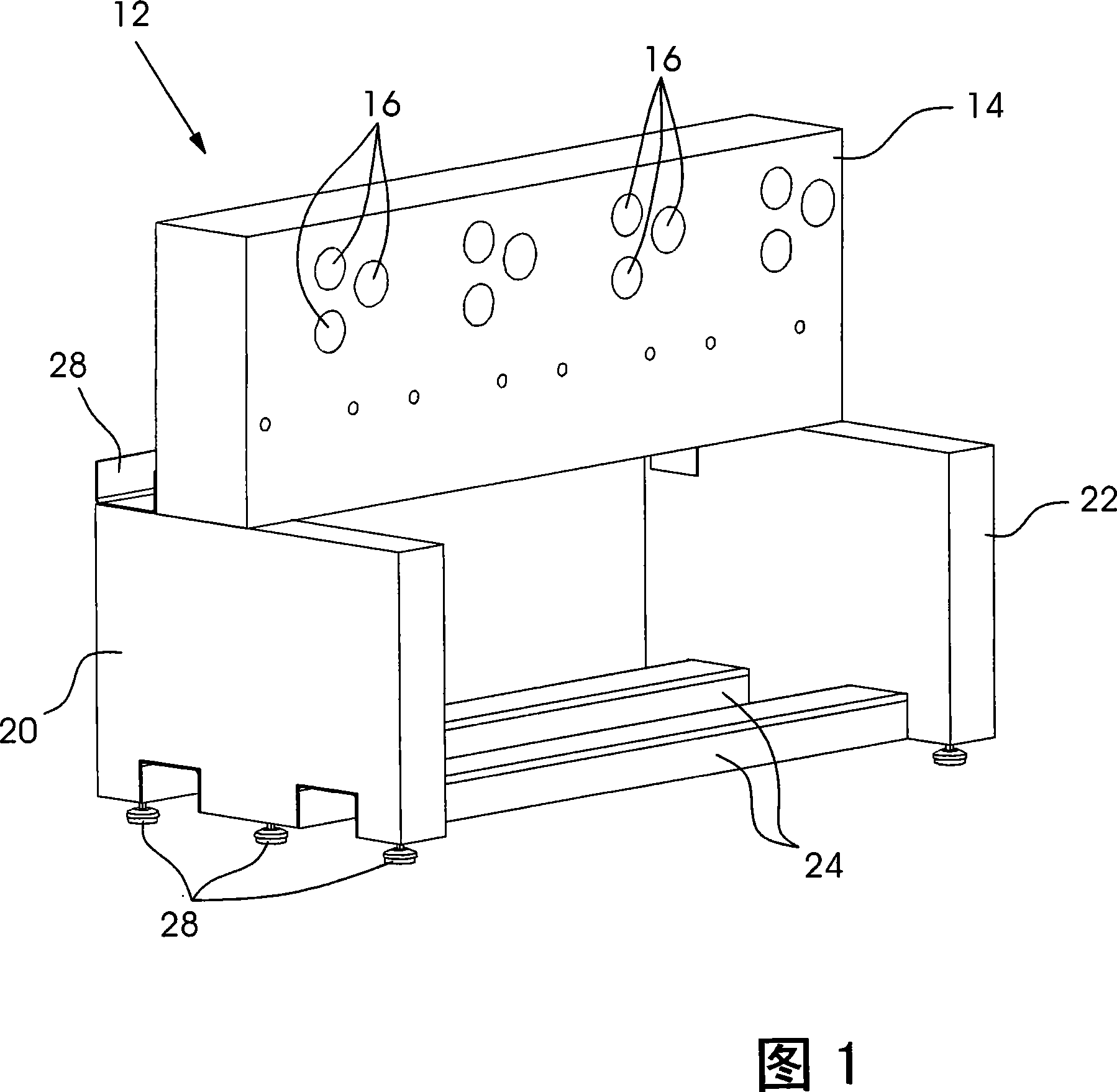

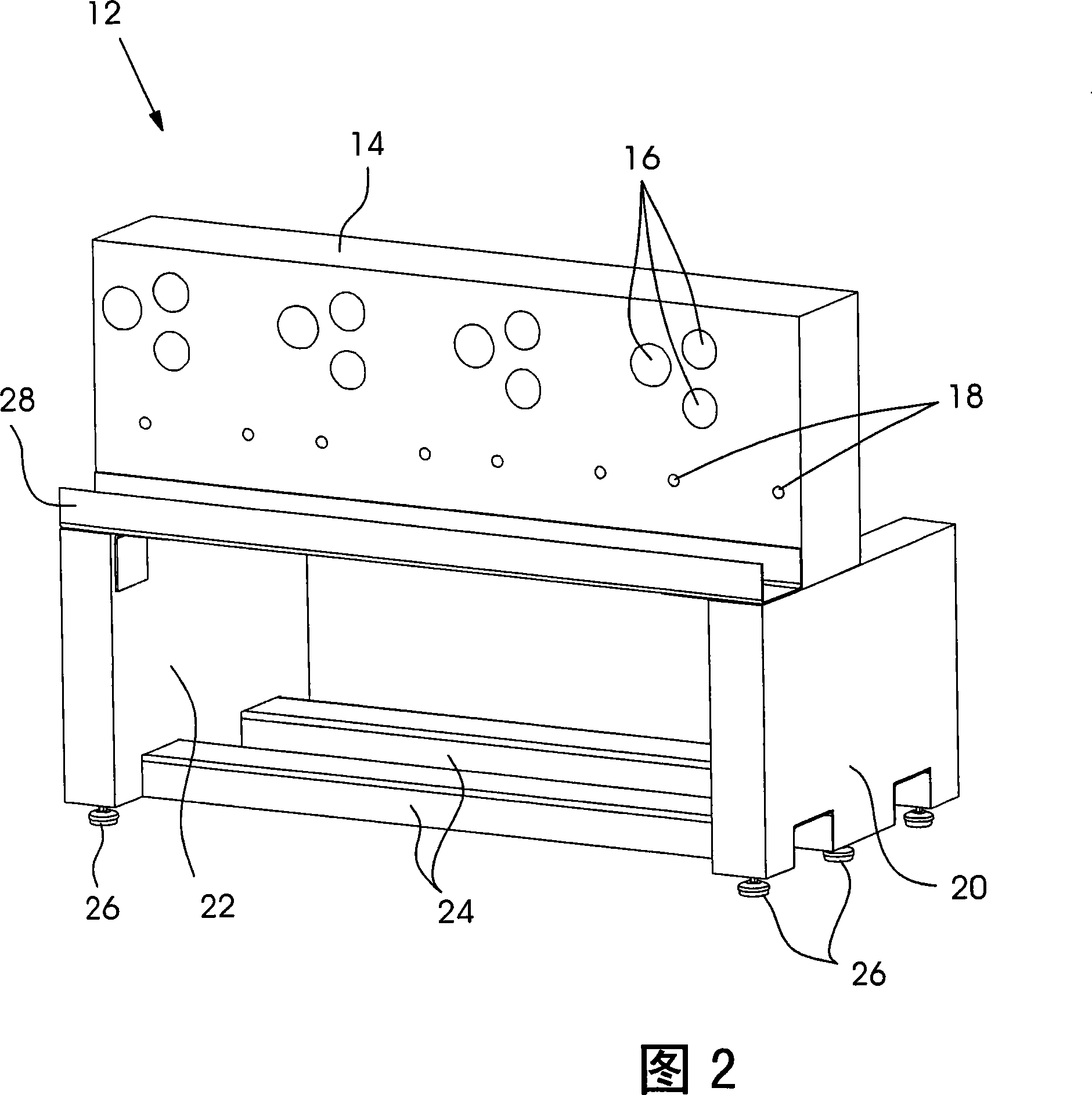

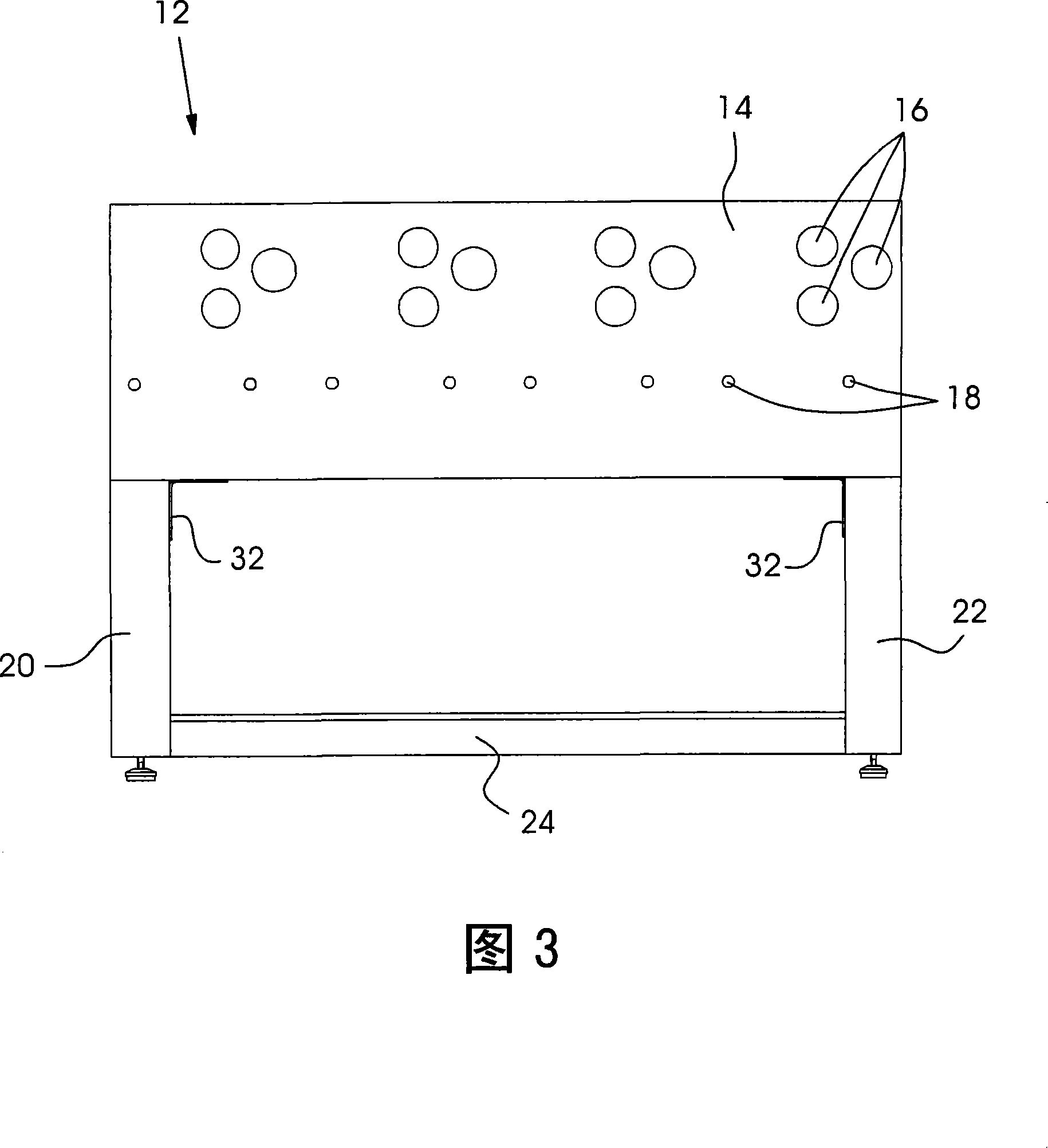

[0037] figure 1 The printing press 10 of the present invention is shown in a view from the operator side (see Figure 5 ) of a preferred embodiment of the machine load-bearing structure 12 consisting of stone load-bearing elements. This embodiment belongs to the first group of embodiments in which natural stone is used. The machine support structure 12 has a support element 14 made of stone, also known as a gantry support, which is used to receive printing units (here, for example, four printing units for standard four-color printing) and other Components - especially the web guide roller here. For this purpose, the carrier element 14 has a plurality of axial bores 16 and other roller bores 18 arranged in groups for the individual printing units. These printing units 30 are arranged horizontally in a serial structure. In this embodiment, the main parts of the framework of the machine support structure 12 , on which the support elements 14 rest, are also made of stone. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com