In-parallel reaction kettles and reaction-kettle-based device for testing induction time of hydrates

A test device and induction time technology, applied in the direction of pressure vessels used in chemical processes, can solve problems such as interference of influencing factors, and achieve the effects of reducing experimental errors, improving experimental efficiency, and efficient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

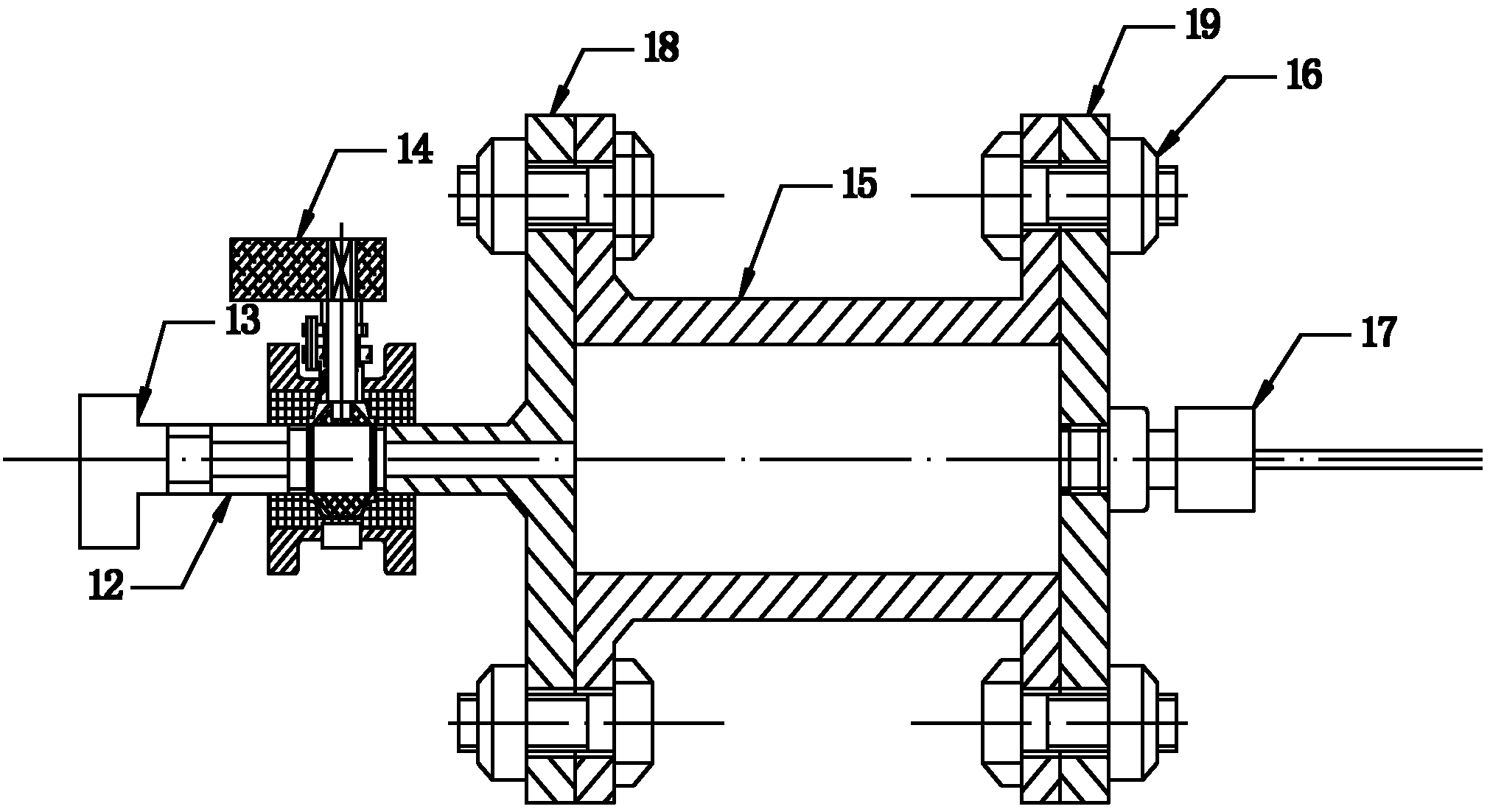

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

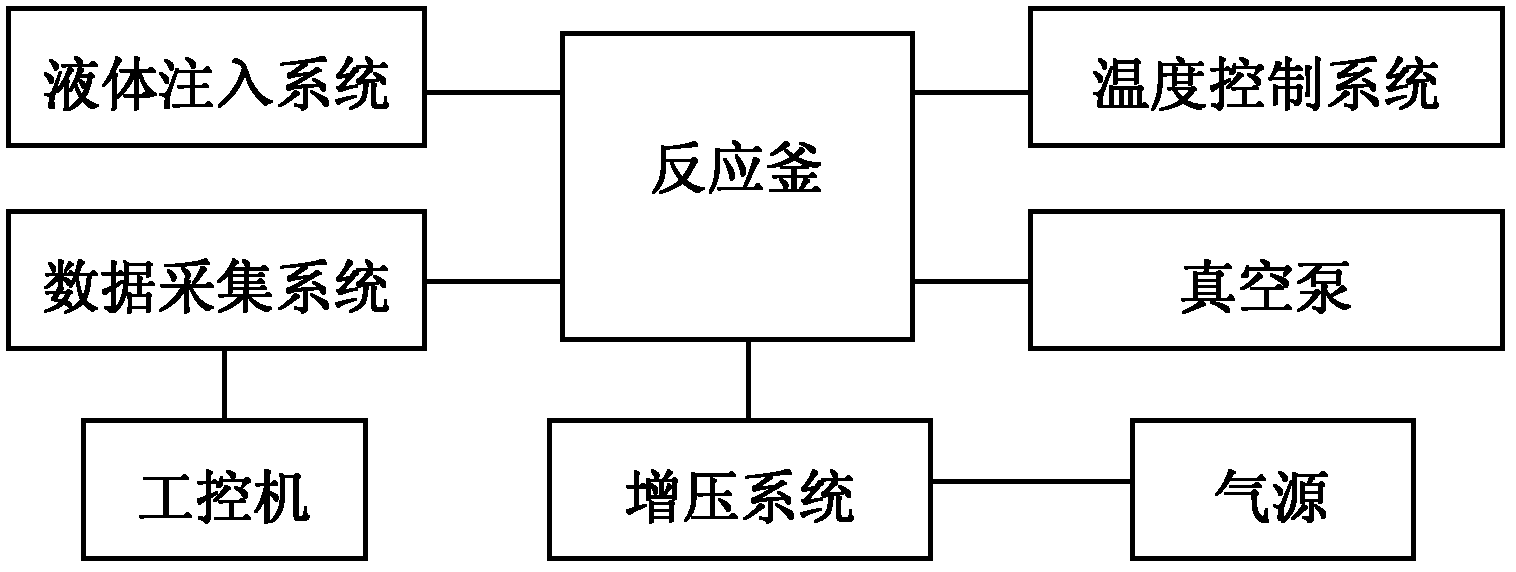

[0022] figure 1 The block diagram of the working principle of the parallel reactor is shown, and its working process is as follows: the experimental test gas is boosted by the gas booster pump and then input into the parallel reactor; Experimental principle, design and control the test conditions in each sub-reactor; the whole system is tested in a constant temperature tank, and the temperature is precisely controlled to promote the formation and decomposition of hydrates; the pressure and temperature in the reactor are measured by pressure transmitters and thermocouples The measurement, temperature and pressure signals are all collected and analyzed in real time by the computer data acquisition system, and then the hydrate formation time is calculated.

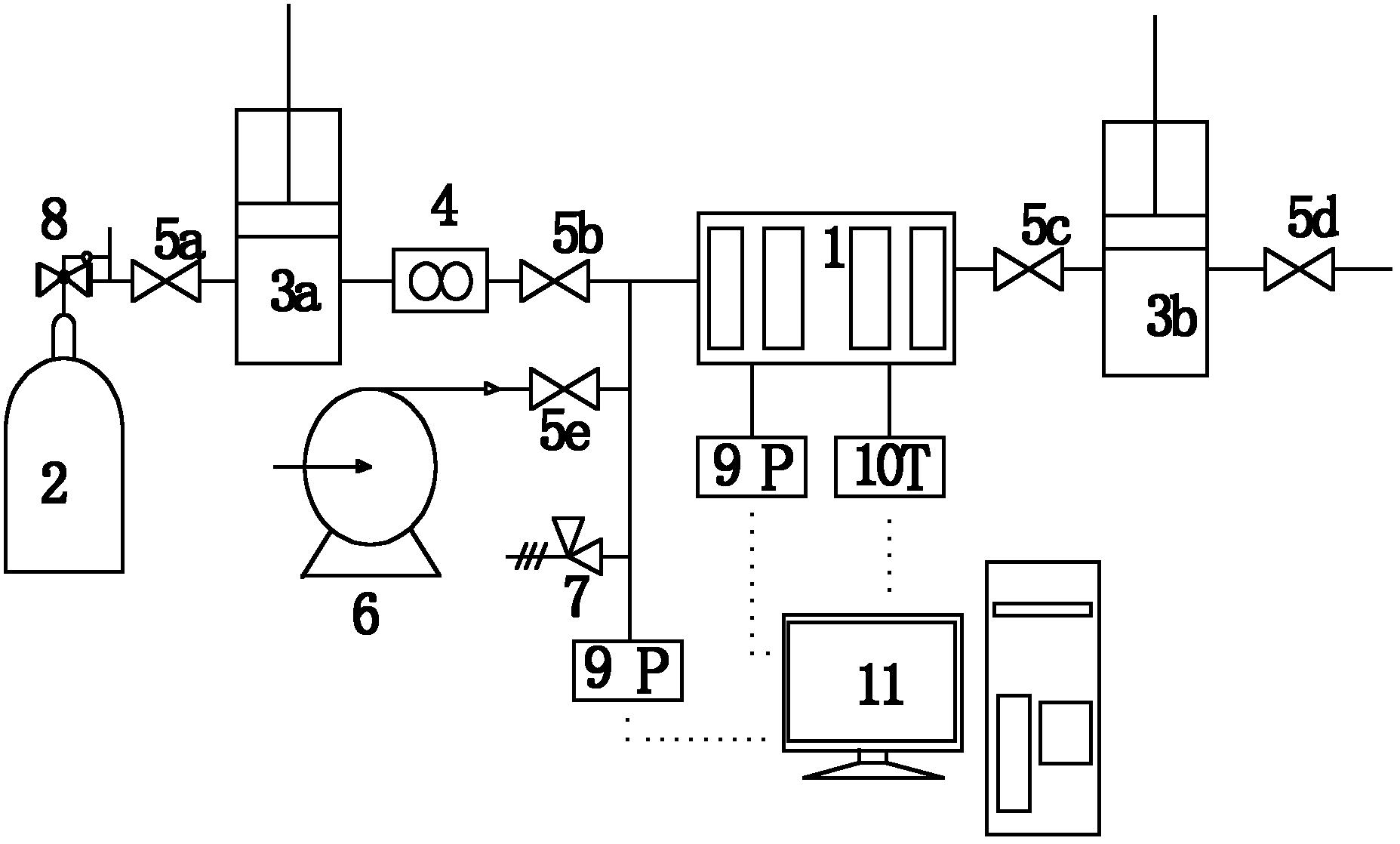

[0023] figure 2 Shown is the system diagram of the inducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com