Device for welding slim tubes with six degree of freedom constrained after being centered and butted

A technology of welding device and degree of freedom, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor weld shape, unsightly deformation, low welding efficiency, etc., and achieve convenient processing and installation, simple mechanical structure, The effect of high centering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

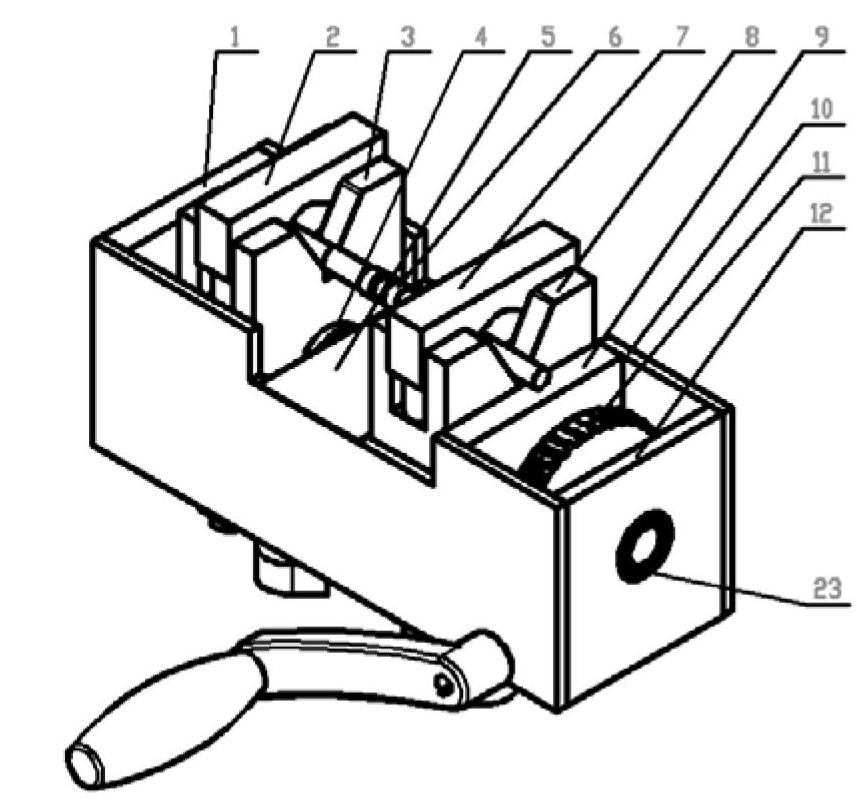

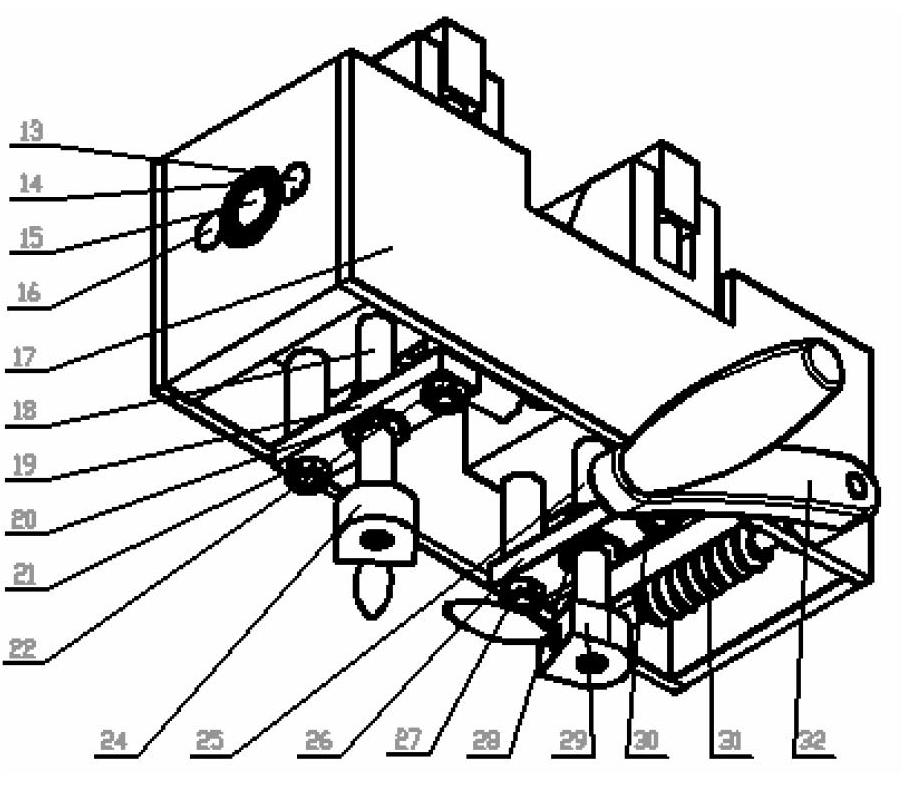

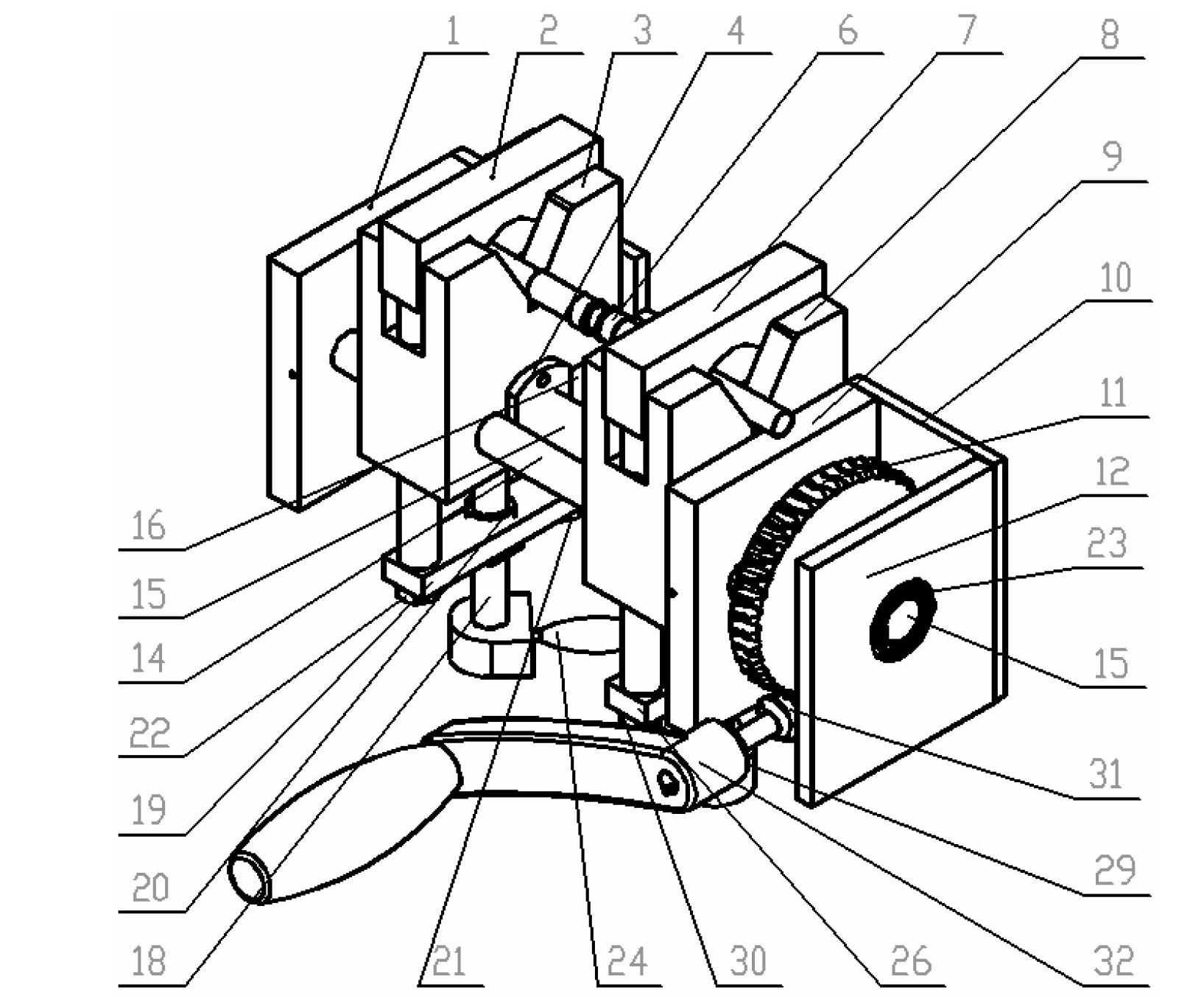

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] Such as figure 1 with figure 2 As shown, the present invention provides a thin tube six-degree-of-freedom centering butt welding device. After the thin tube workpiece 6 to be centered and butt-jointed is subjected to the action of the axial centering mechanism I and the axial centering mechanism II, the shaft The centering accuracy reaches the welding standard, and now the crank handle 32 is shaken to pull the axial butt joint mechanism to run, so that it can complete the butt joint task before the pipe welding. The structure of the device in this embodiment is consistent with that in the summary of the invention, and will not be repeated here.

[0026] The working principle of the present invention is as follows:

[0027] Such as Figure 4 with Figure 7 As shown, use the fork lock I2 to clamp one end of the thin tube workpiece 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com