Valve grinding and maintaining machine tool

A grinding and valve technology, applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of poor working strength, poor mechanical properties and rigidity, and too simple structure, and achieve strong rigidity and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

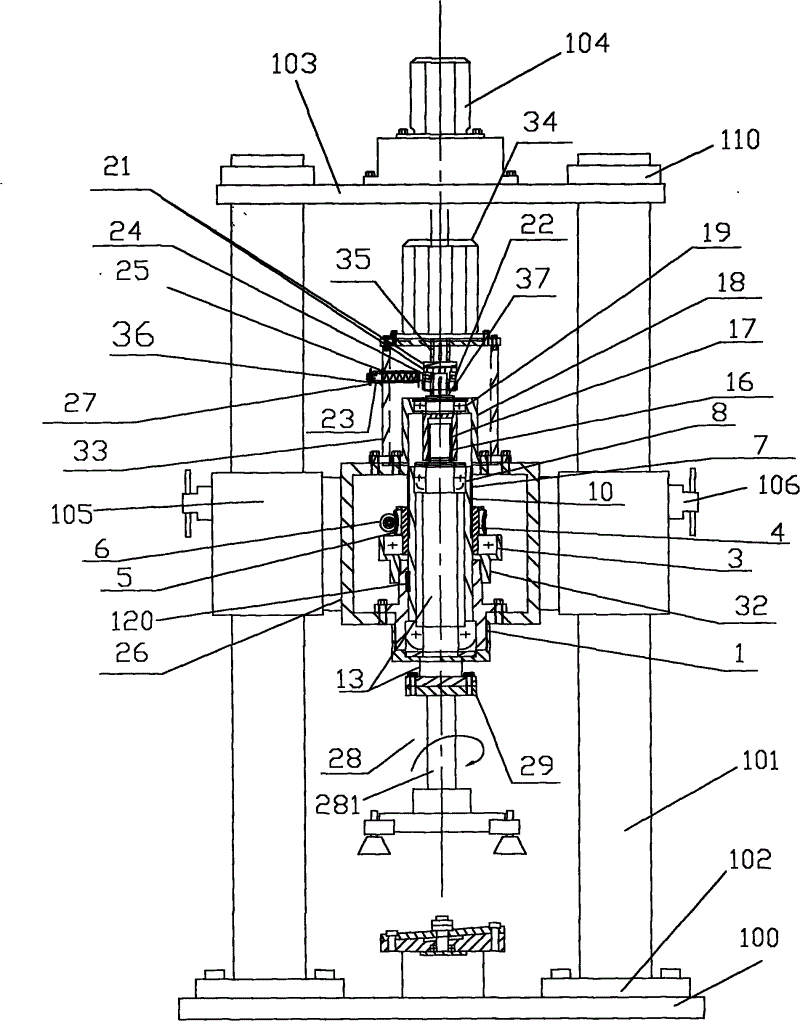

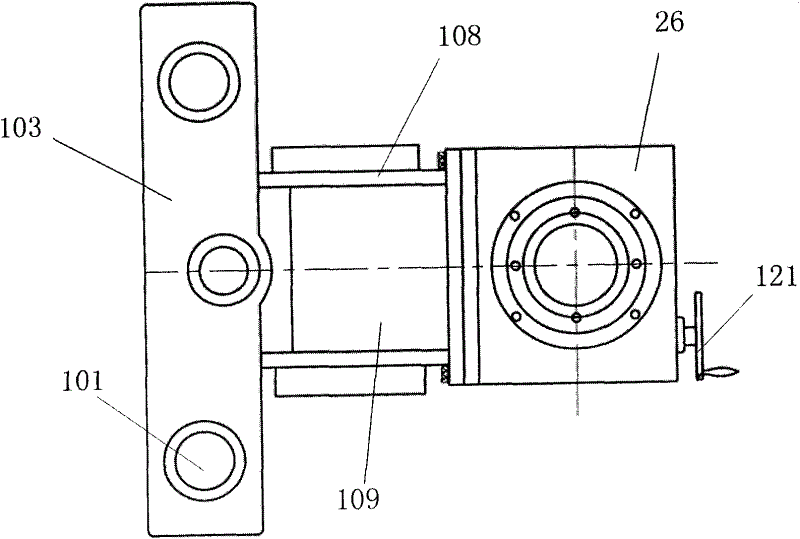

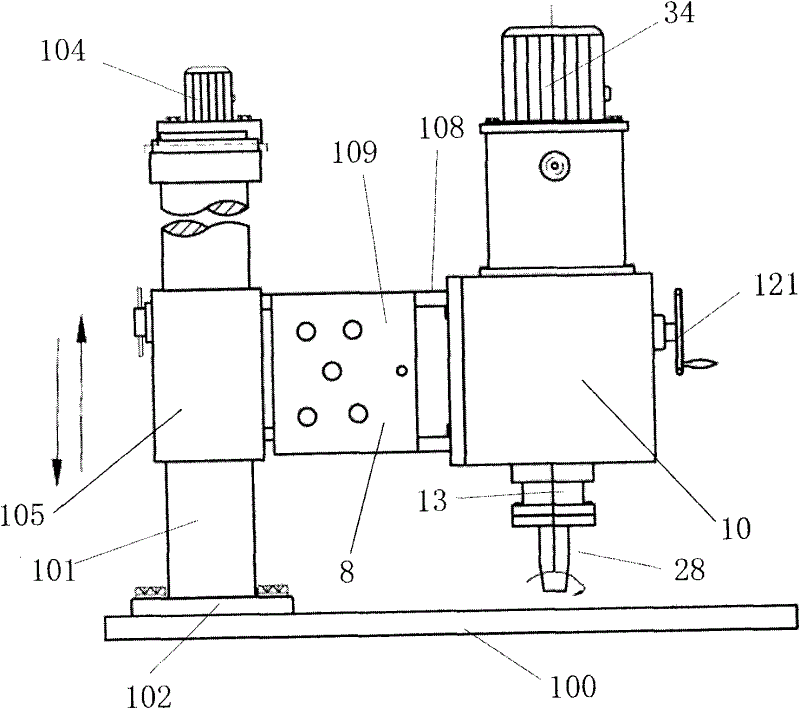

[0058] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the valve grinding and maintenance machine tool of the present invention has a workbench 100. Columns 101 are respectively arranged on both sides of the workbench 100. The chassis 102 at the bottom of the column 101 is fixed on the workbench 100 with screws and reinforced with taper pins. The upper ends of the columns 100 are connected with lifting beams 103, and the two ends of the lifting beams 103 are respectively sleeved on the upper ends of the two columns 101, and compressed with lock nuts. The function of 103 on the lifting beam is to carry Figure 4 Lifting mechanism shown. Two upright posts 101 are provided with upright sleeve 105 respectively, and upright sleeve 105 is provided with upright locker 106, and so-called upright locker 106 is a screw rod that is scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com