Hydraulic traveling differential mechanism of snow blower

A differential mechanism and snow blower technology, applied in the field of hydraulic systems, can solve problems such as vehicle impact, safety valve overflow, energy loss, etc., to achieve the effect of overcoming vehicle impact, ensuring reliability and safety, and overcoming energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the technical content, characteristics and effects of the present invention, the following examples are listed hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

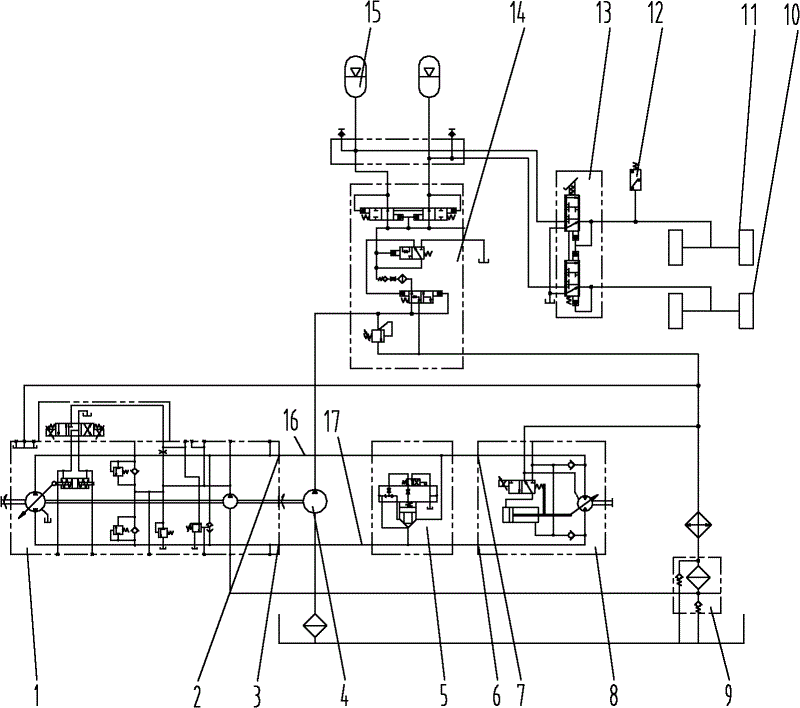

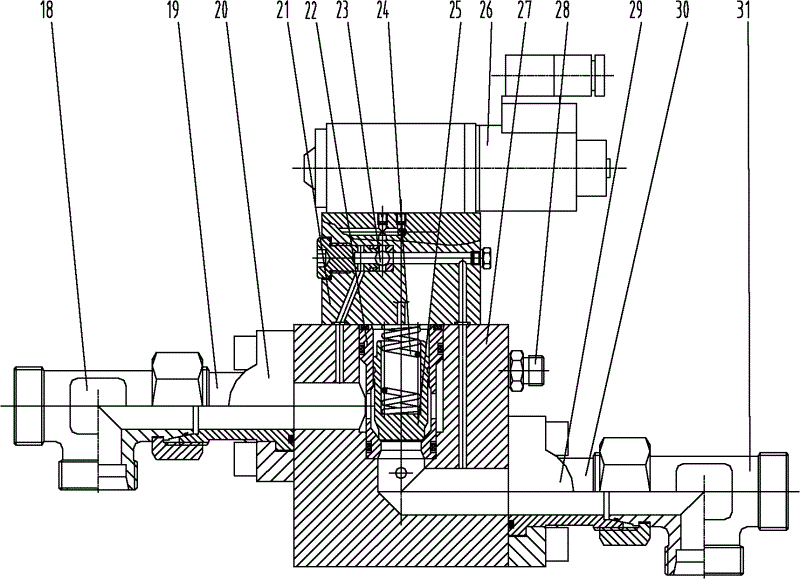

[0012] Refer to attached figure 1 , figure 2 : snow blower hydraulic travel differential mechanism, including travel hydraulic system, brake hydraulic system; described travel hydraulic system includes electric proportional variable pump 1 and electric proportional variable motor 8; oil port A 2 of electric proportional variable pump 1, Oil port B 3 is connected to oil port AA 7 and oil port BB 6 corresponding to the electric proportional variable motor 8, wherein the connecting pipeline between oil port A 2 and oil port AA 7 is oil line A 16, and oil port B 3 is connected to oil port The connecting pipeline of BB 6 is oil circuit B 17; the brake hydraulic system includes a hydraulic pump 4, a filling valve 14, a pedal brake valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com