Apparatus and method for utilizing compressed gas and liquid to connect spinning line or yarn, and device for feeding liquid to the apparatus

A technology for compressed gas and textile threads, which is applied in the field of equipment for connecting textile threads or yarns with compressed gas and liquid and devices for supplying liquid to the equipment, and can solve the problems that the length of the container cannot be controlled all the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

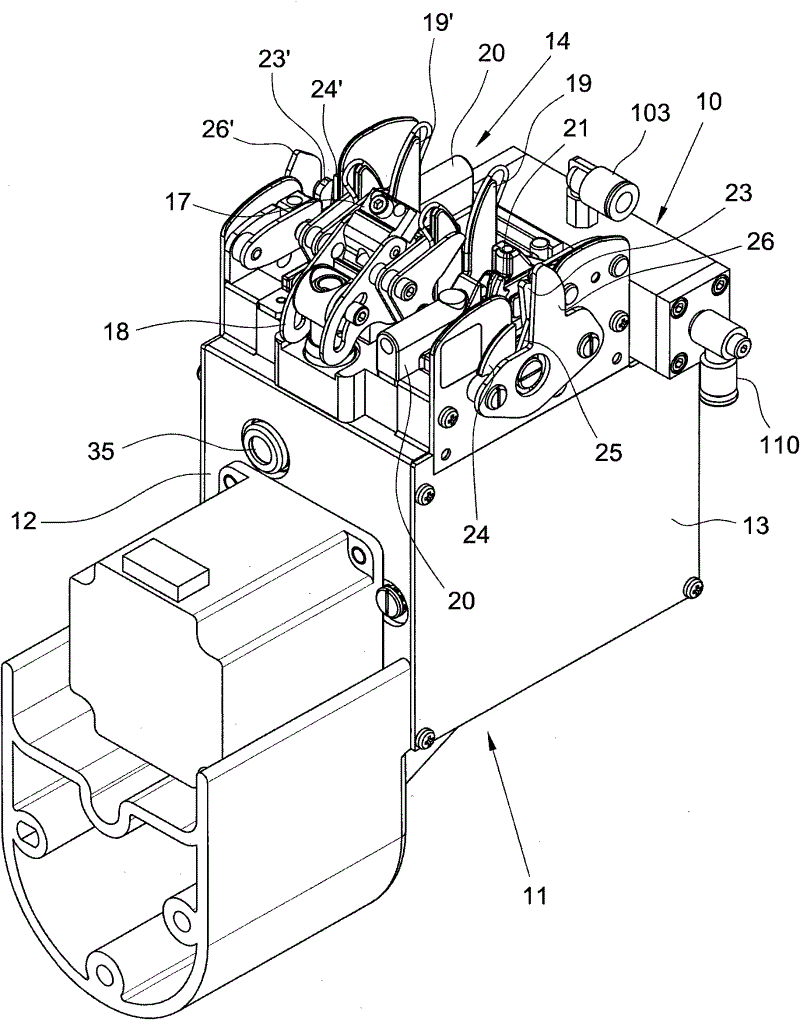

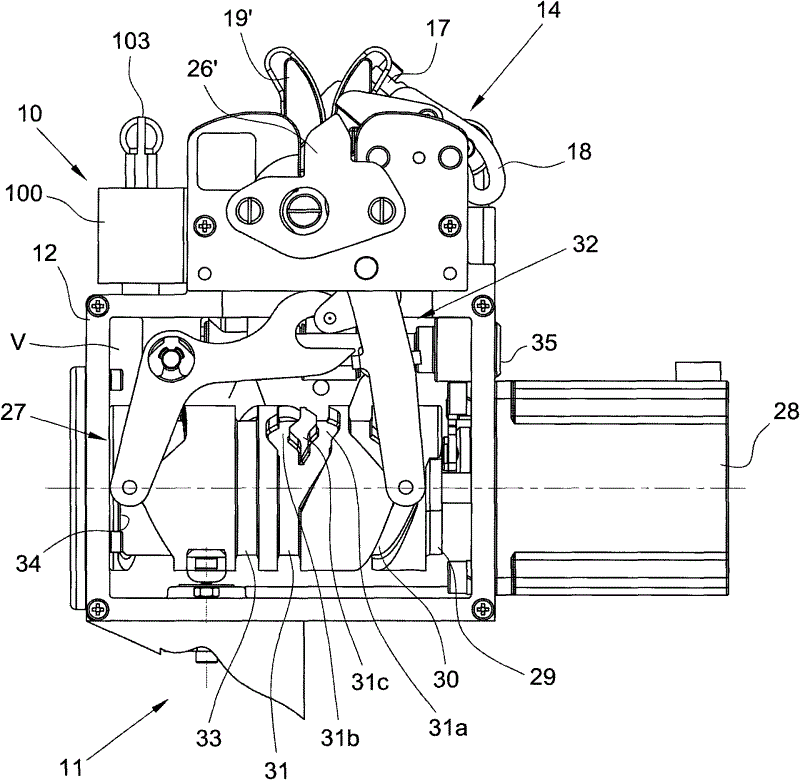

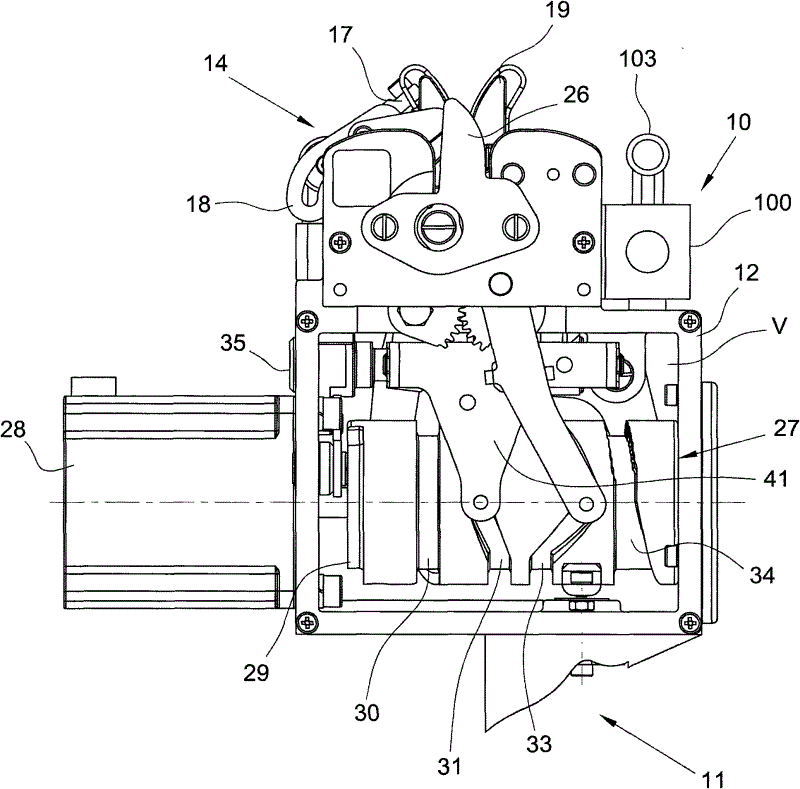

[0039] Referring to the accompanying drawings, means for supplying liquid to a device 11 for joining textile threads or yarns using compressed gas and liquid are generally indicated by the reference numeral 10 .

[0040] refer to Figure 7 and Figure 8 , which first schematically shows a part of an automatic winding machine 200 of known type and provided with a plurality of workstations I to V. A computer-controlled electronic unit generally indicated by reference numeral 201 is provided at the forefront of the automatic winding machine 200, with which computer-controlled electronic unit, the control mechanism for operating the automatic winding machine 200 and its components can be provided and assign.

[0041] Figure 8 Each work station shown schematically in the figure basically includes: a bobbin 210 from which the thread or yarn to be wound is released; a detection device 202, termed in the art as a "clearer", is adapted to control the continuity and status, in part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com