Combined integrated energy-saving adjustable electrical control pneumatic electrolytic aluminum crust breaking system

A shelling system and integrated technology, applied in the field of electrolytic aluminum shelling control, can solve problems such as cylinder block leakage, achieve high energy saving efficiency, obvious energy saving effect, and short investment payback period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

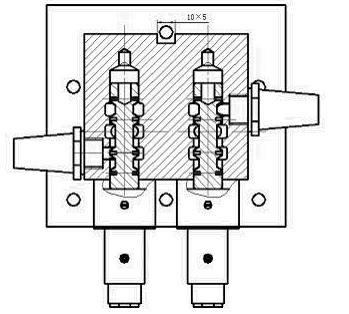

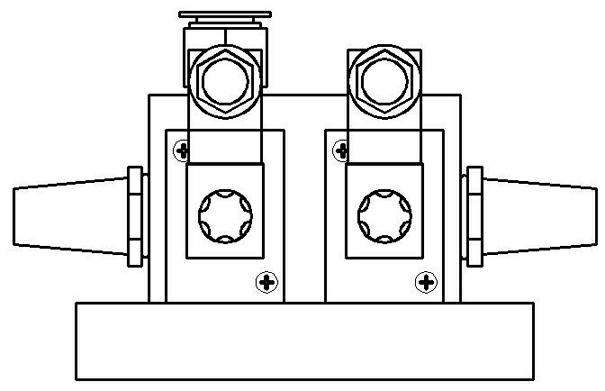

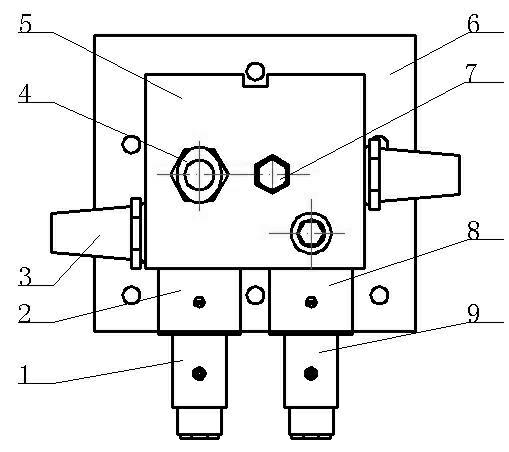

[0017] The invention of the combined energy-saving and adjustable electric-controlled pneumatic electrolytic aluminum shelling system is used for the electro-pneumatic circuit of electrolytic aluminum production equipment, and is installed on the cylinder head. As shown in the figure: 1—solenoid valve-coil, 2—solenoid valve-armature, 3—muffler (2 pieces), 4—air inlet pipe joint, 5—valve body, 6—base, 7—throttle valve , 8—the second armature of the solenoid valve, 9—the second coil of the solenoid valve. The control device of the high-efficiency and energy-saving pneumatic electrolytic aluminum shelling system includes the air source inlet, the first and second two electromagnetic reversing valves, the air source inlet passes through the passage of the two electromagnetic reversing valves, and the two electromagnetic reversing valves There is a throttling valve on the path of the valve, and then connected to two outlets (air outlets) on the control device, the two outlets on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com