Back-insert steel reinforcement cage cement-flyash-gravel pile and pile-forming method thereof

A technology of cement fly ash and gravel piles, applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of high uneven settlement requirements and high processing costs, and achieve obvious social and economic benefits, and enhance the level Shear strength, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

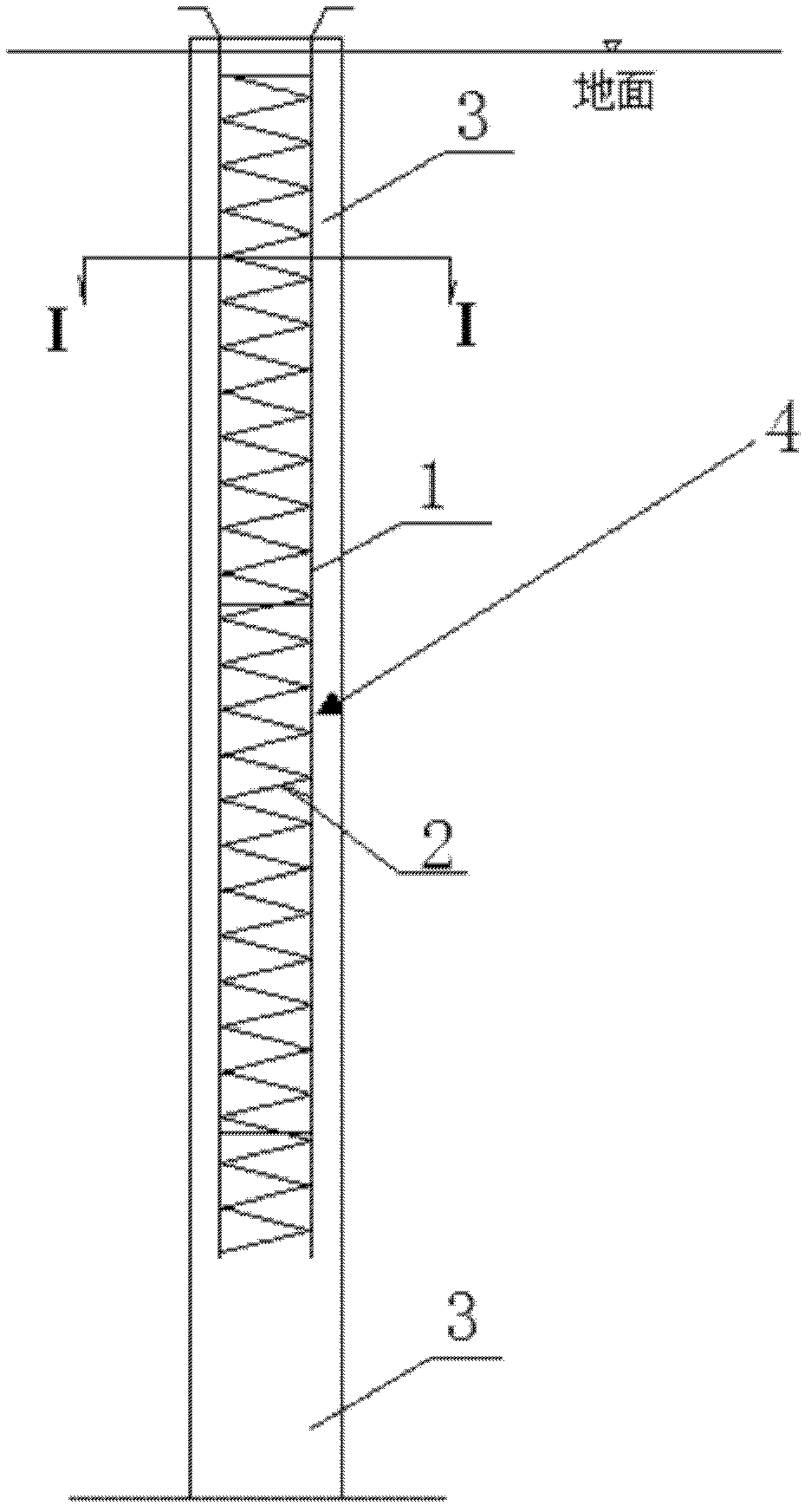

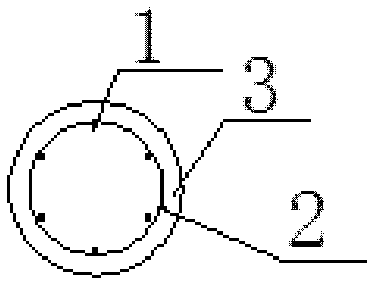

[0031] As shown in the figure, the post-inserted reinforced cage cement fly ash macadam pile includes a cement fly ash macadam mixture filling layer 3, and it also includes a cage frame 4 mainly composed of several main reinforcements 1 and stirrups 2 fixedly connected. The filling layer 3 of cement, fly ash and gravel mixture is densely filled inside the cage frame 4 and extends to cover the outer periphery of the cage frame 4 . Above-mentioned cage frame 4 is a reinforcement cage.

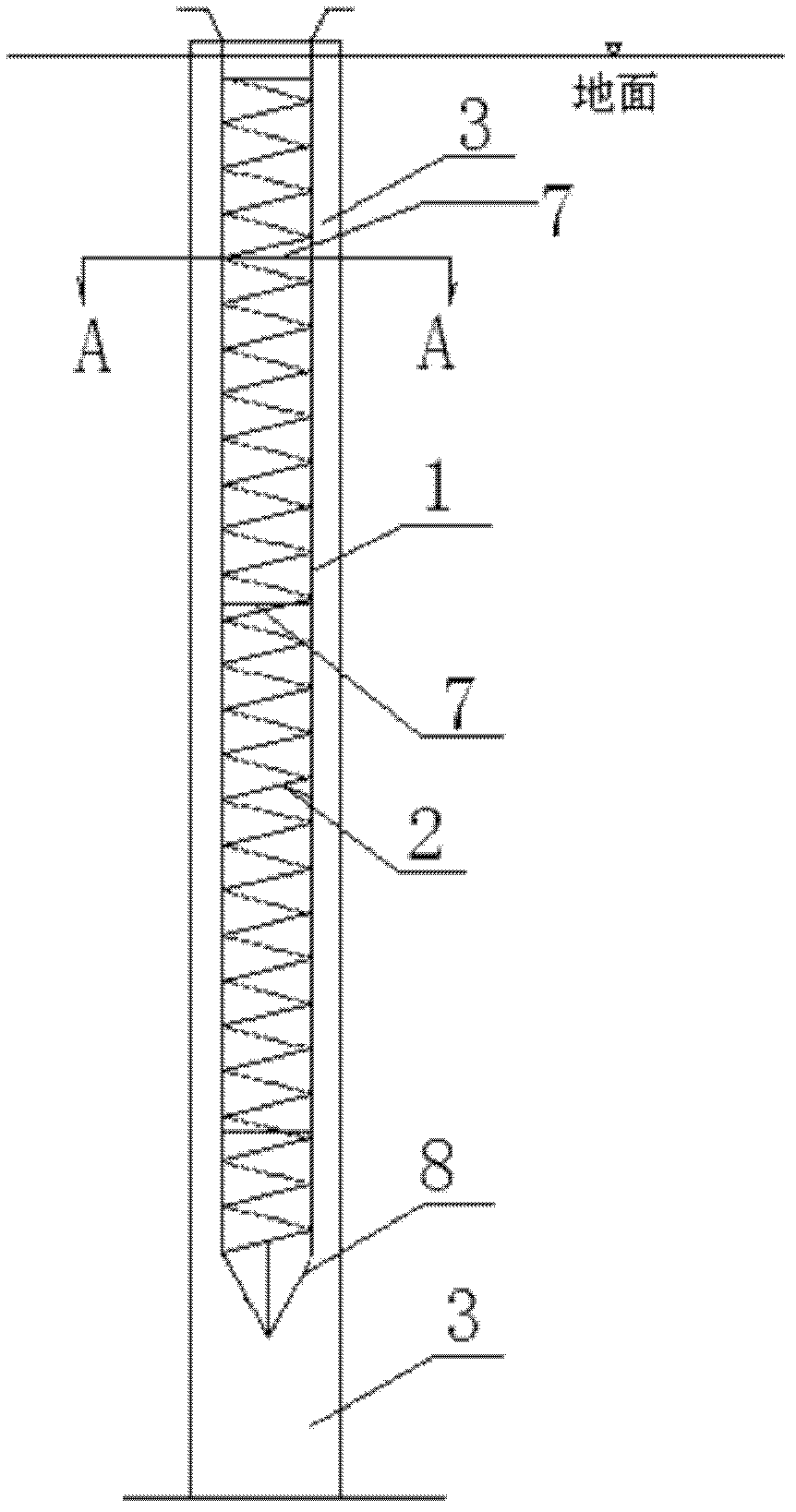

[0032] In the above technical solution, when the length of the cage frame 4 is ≥ 6m, the bottom of the cage frame 4 is designed as a conical frame 8, and the cage frame 4 is provided with several radial reinforcement bars 7, and several radial reinforcement bars 7 Forming a reserved space 9 inside the radial steel bars in the cage frame 4, and the reserved space 9 inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com