Reinforced concrete stair with local steel plate type sliding device on support

A technology of reinforced concrete and sliding device, applied in the direction of mobile stairs, stairs, pedals, etc., can solve the problems of increased sliding friction, too large sliding surface, uneconomical, etc., to reduce the contact friction surface and reduce friction. Resistance, the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

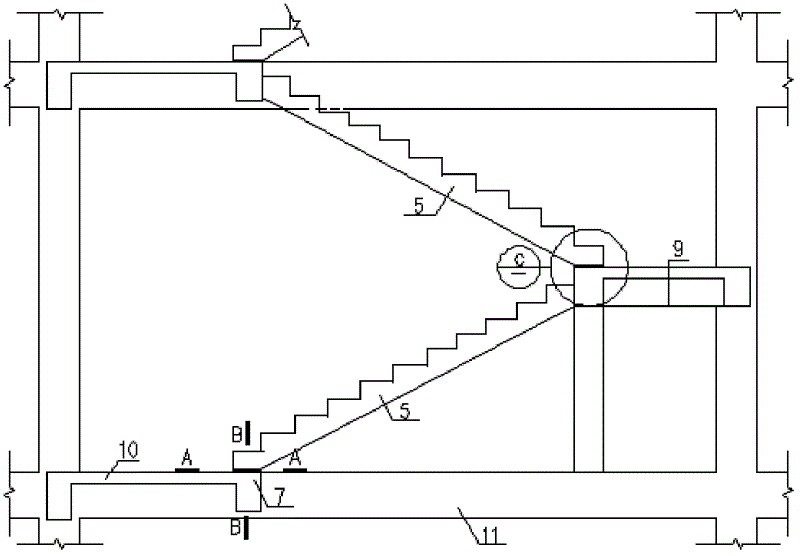

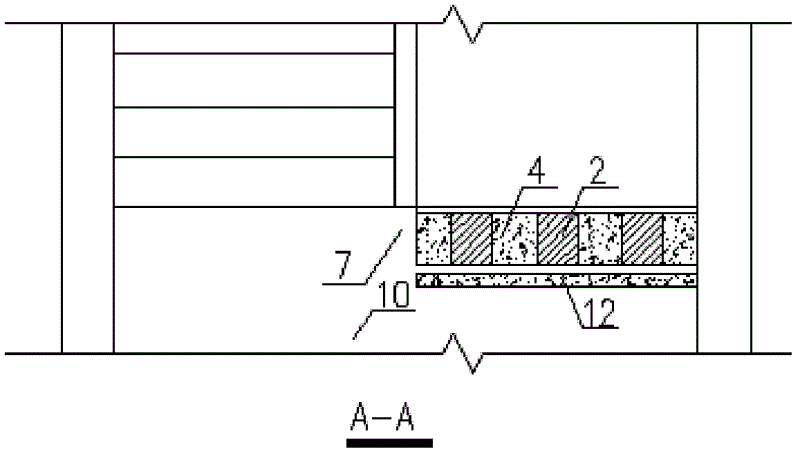

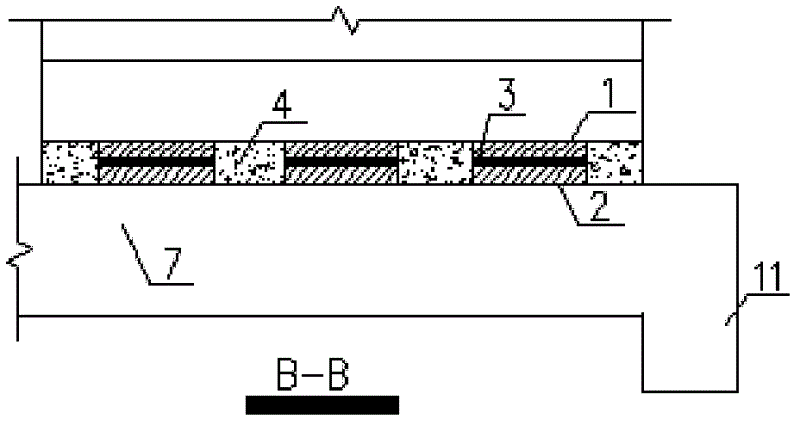

[0026] Figure 1 ~ Figure 4 It is the application of reinforced concrete stairs with local steel plate type sliding device on the support when the lower end is supported on the ladder beam. During construction, first pour the lower reinforced concrete beam 11, platform slab 10, and ladder beam 7; when pouring the ladder beam 7, on its upper surface, at certain intervals along the width direction of the ladder section 5, set the concrete protruding from the ladder beam 7 A row of pre-embedded steel plates 2 under the support on the surface; after the concrete of the ladder beam 7 has hardened, set the pre-embedded steel plates 1 on the support at all corresponding positions of the lower end of the ladder slab 5 and the embedded steel plate 2 under the support, and It protrudes from the concrete surface at the lower end of the step slab 5; the embedded steel plate 1 on the support is located above the embedded steel plate 2 under the support, and the surface is in contact with the...

Embodiment 2

[0029] Figure 5 ~ Figure 8 It is the application of reinforced concrete stairs with local steel plate sliding device on the support when the lower end is supported on the ladder beam cantilever. During construction, pour the lower reinforced concrete beam 11, platform slab 10, ladder beam 7 and ladder beam cantilever 8. The length of the ladder beam cantilever 8 is taken as the width of the bottom step of the ladder plate 5, and its thickness is not less than that of the ladder. The thickness of the section plate 5; when pouring the ladder beam pick plate 8, set the embedded steel plate 2 under the support on its upper surface according to the same method as in Example 1, and complete all subsequent manufacturing processes the same as in Example 1, thereby forming The support is equipped with a reinforced concrete staircase with a partial steel plate type sliding device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com