Hole sealing method for gas drainage drill

A technology of gas drainage and composition, which is applied in the direction of gas discharge, earthwork drilling, sealing/package, etc., can solve the problems of reducing foaming ratio, increasing the amount of polyurethane material liquid, and short service life, so as to reduce the material Dosage, increase foaming ratio, improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

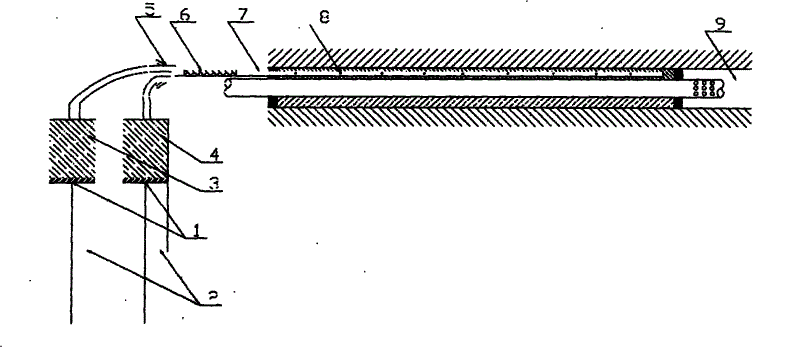

Embodiment 1

[0017] Two material cylinders with an inner diameter of 100mm are fixed side by side on the frame, and the tails of the piston rods are hard connected with connecting rods. Put the flexible packaging bag containing 1000ml of components A and B into the material tank, connect the discharge port to the five-way, and connect the compressed air to the five-way, one port of the five-way is connected to the mixing element, and the mixing element is connected to the The material liquid delivery pipe, the length of the feed liquid delivery pipe entering the inside of the gas borehole is 9500mm, and there is a discharge port with a diameter of 1.5mm every 1000mm on the pipe wall. Use compressed air to push the pistons of the two material cylinders to advance synchronously, inject the material, mix it with the compressed air in the bottom bracket, and then mix it into the material liquid in the mixing element. The material liquid flows out to the gas through the outlet on the wall of the...

Embodiment 2

[0019] With embodiment 1, in the middle of the material cylinder of two inner diameters 100mm that are discharged into side by side, increase the air cylinder of an inner diameter 40mm as additional power, the afterbody of 3 piston rods is hard-connected with connecting rod, and other is identical. The time required for injection is 50 seconds.

Embodiment 3

[0021] Same as in Example 1, the material tank in which component B is placed is replaced with a material tank with an inner diameter of 80mm, the dosages of components A and B are 1000ml and 640ml respectively, and the others are the same. The reaction ratio of A and B materials is 100:64 (volume ratio).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com