SCR (Selective Catalytic Reduction) system of electrical control diesel engine and control method of SCR system

A technology of SCR system and control method, applied in the control field of SCR system of electronically controlled diesel engine, can solve the problems of high cost, long research and development cycle, poor strategy ductility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The core of the invention is to provide a method for controlling the SCR system of an electronically controlled diesel engine. Based on the model, this method is applicable to almost all diesel engines. The follow-up work of the manufacturer is to carry out corresponding calibration tests for different models, which will reduce costs, shorten the development cycle, and greatly improve the performance of SCR systems and diesel engines. R & D efficiency of the complete machine factory.

[0029] Another core of the present invention is to provide an electronically controlled diesel engine SCR system using the above control method.

[0030] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

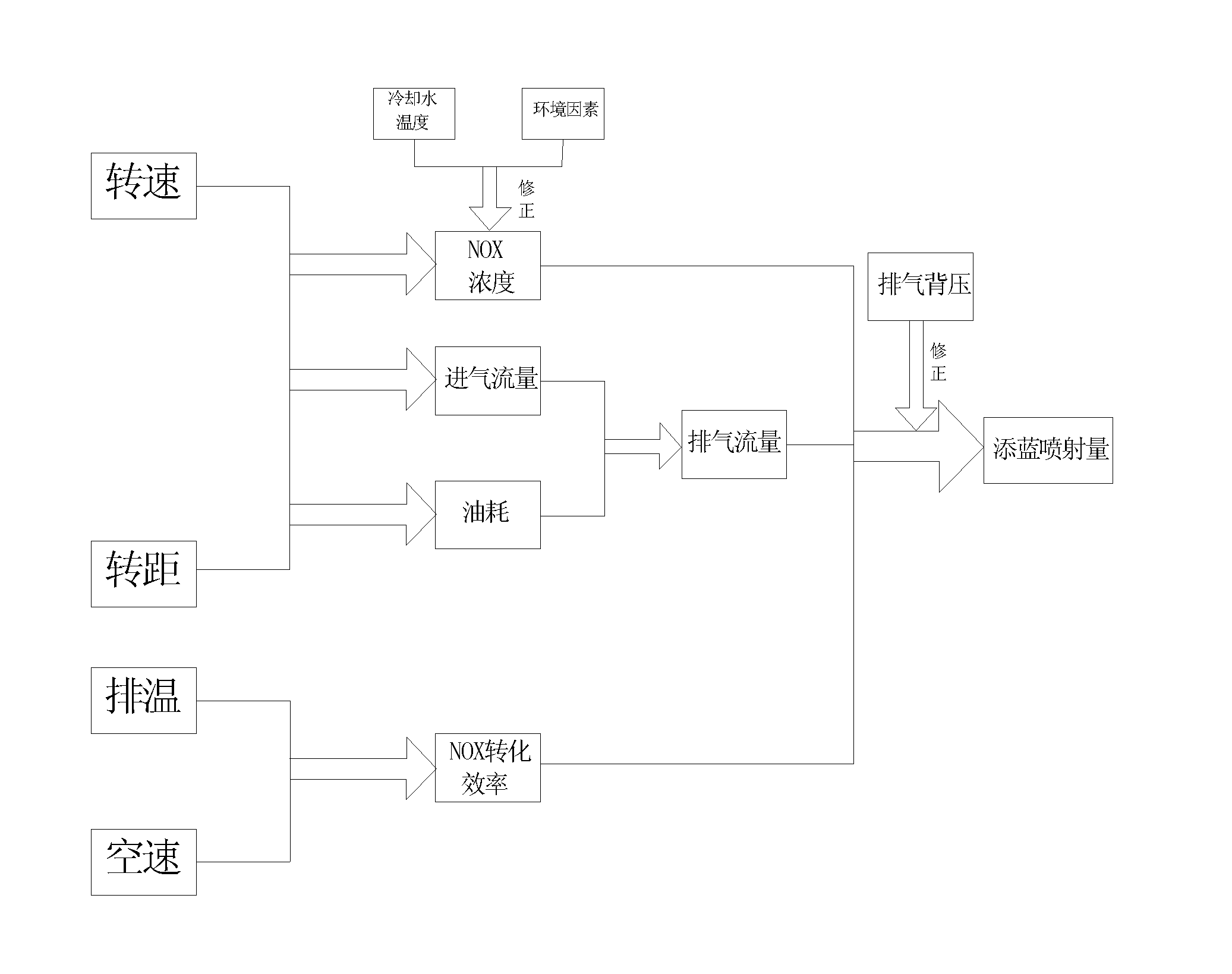

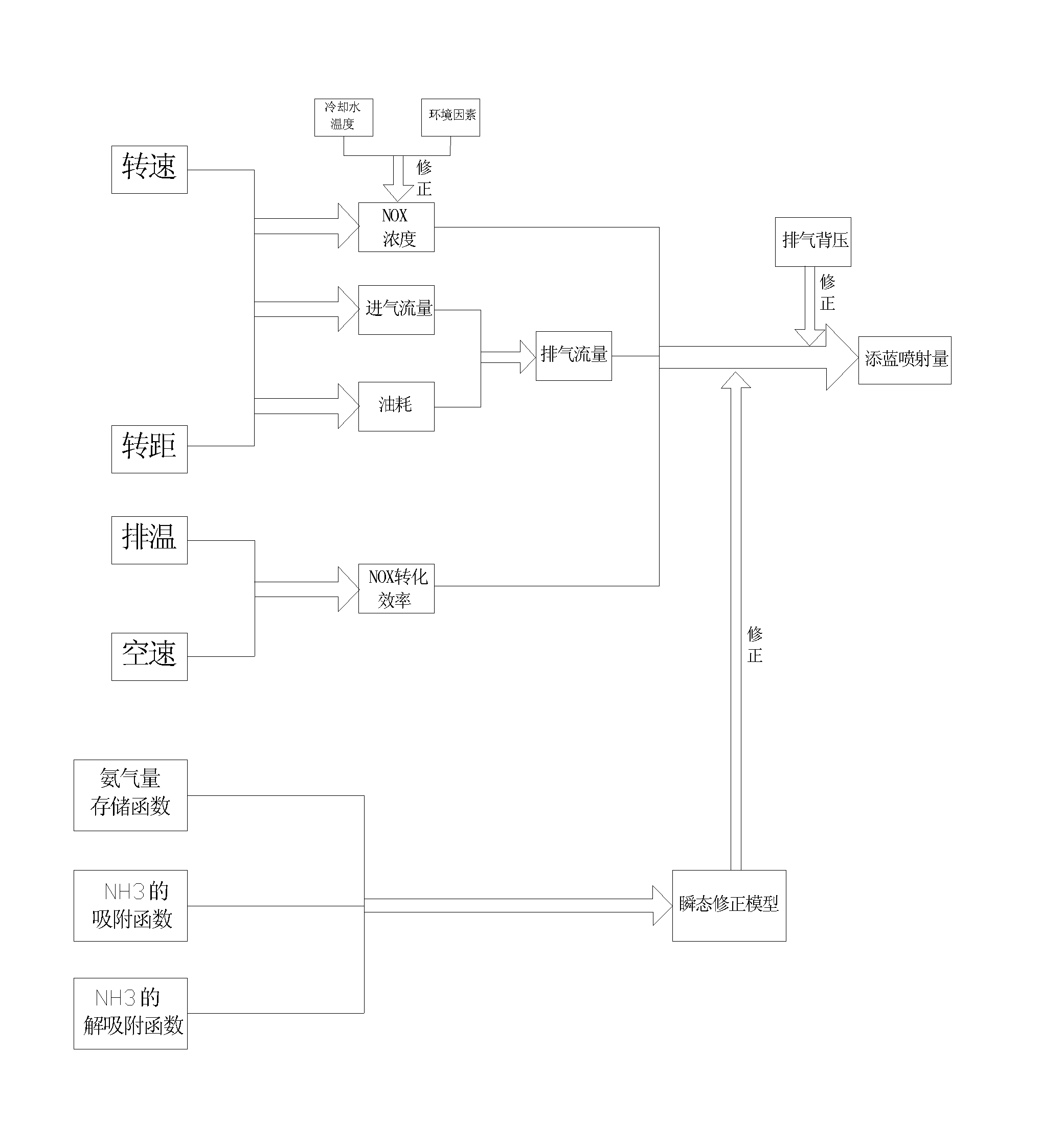

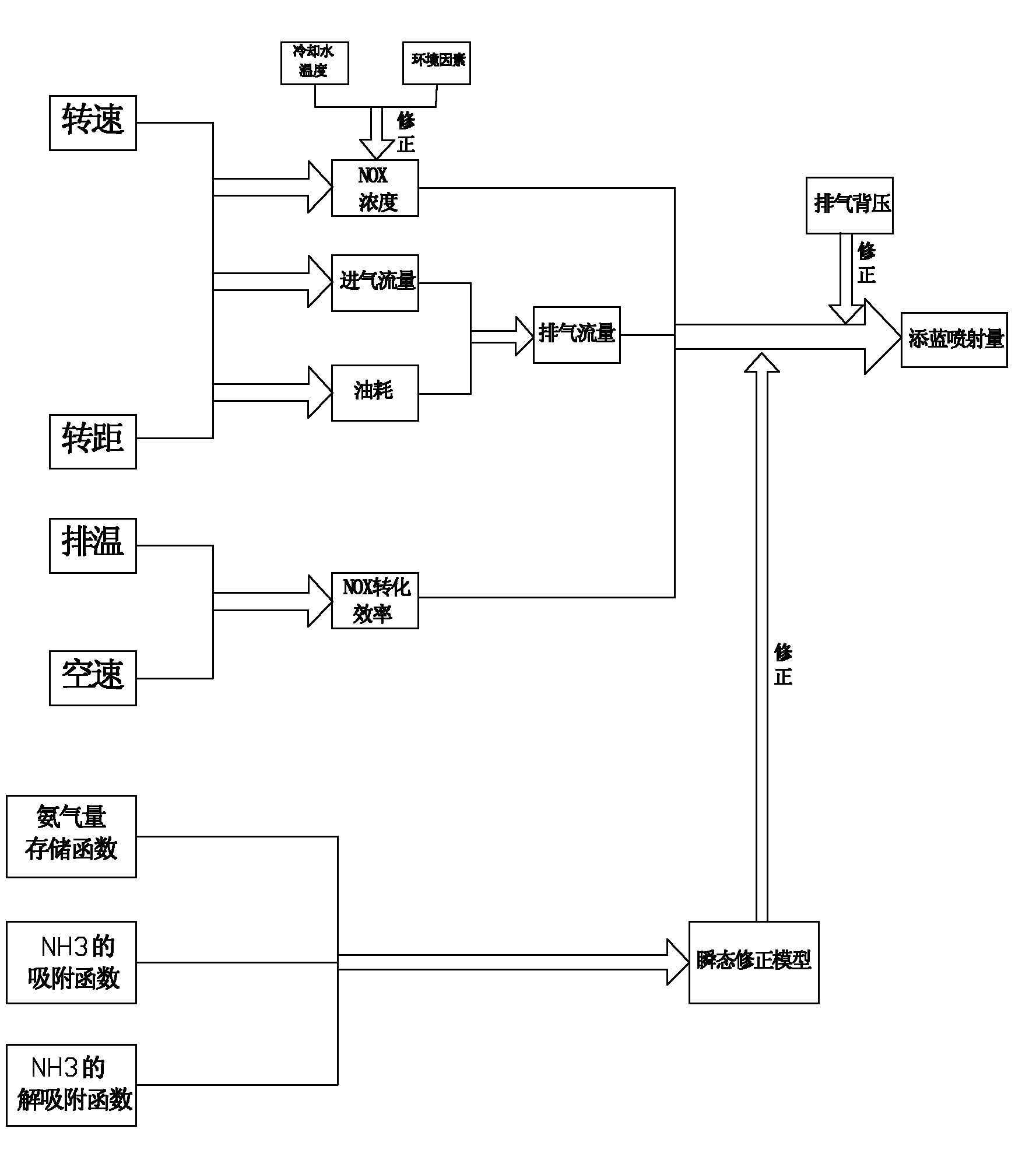

[0031] Please refer to figure 1 , figure 1 It is a control flow chart for determining the blue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com