Integrated shaft-free motor axial flow pump

A motor shaft and shaftless technology, which is applied to liquid fuel engines, pumps, components of pumping devices for elastic fluids, etc., can solve the problems of high dynamic seal design requirements, inconvenient installation, complex structure, etc., and achieve easy construction Design, small footprint and simple system layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

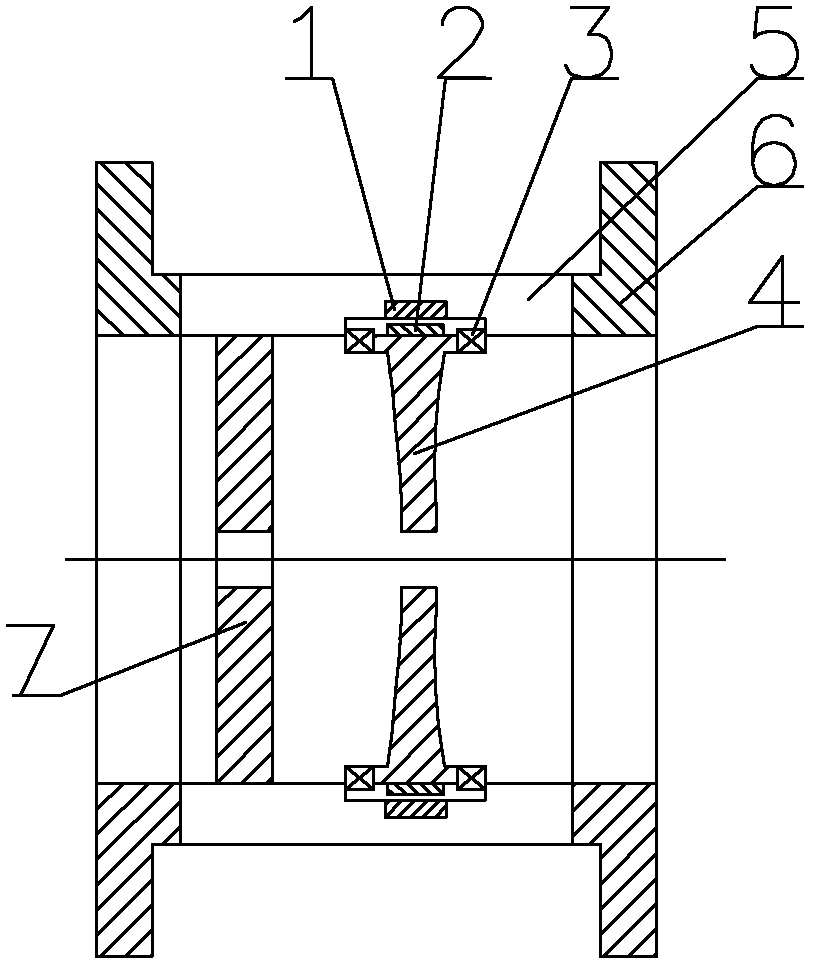

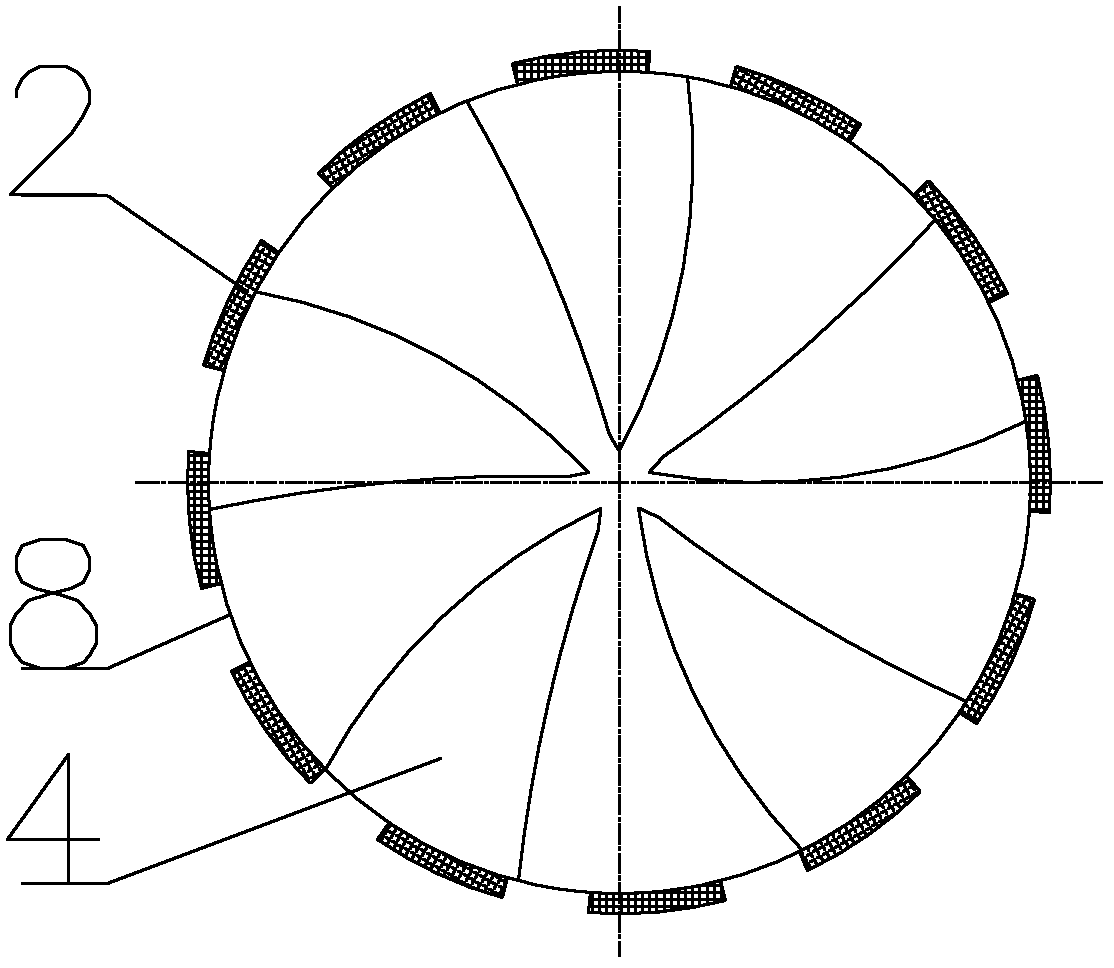

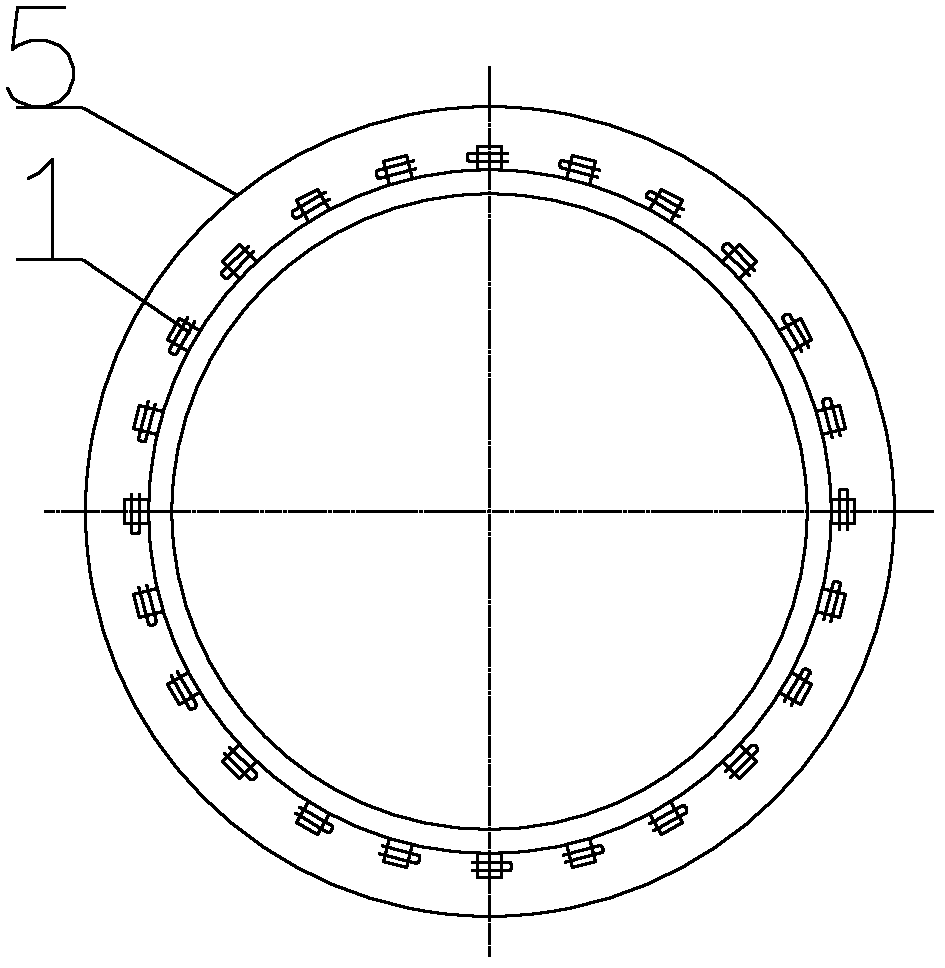

[0021] Such as figure 1 , 2 , 3, the integrated shaftless motor axial flow pump of the present invention includes:

[0022] There are pump casings 5 with connecting flanges 6 at both ends, the pump impeller 4 is located in the center of the inner cavity of the pump casing 5, and guide vanes are arranged in the inner cavity of the pump casing 5 located on the downstream side of the axial flow pump. 7. Install the axial flow pump in the pipeline through the flange 6, for example: bolts, nuts and other fasteners can be used to connect the axial flow pump to the upstream and downstream pipelines through the connecting flange 6 at both ends of the inlet and outlet;

[0023] The outer edge of the pump impeller 4 is provided with a rotor fixing ring 8, and the drive motor rotor 2 is assembled on the rotor fixing ring 8,

[0024] The rotor fixing ring 8 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com