Efficient energy-saving adjustable electronic control electrolytic aluminum crust breaking valve terminal system

A high-efficiency, energy-saving, electrical control technology, applied in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve problems such as cylinder leakage, and achieve the effects of high energy-saving efficiency, simple installation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

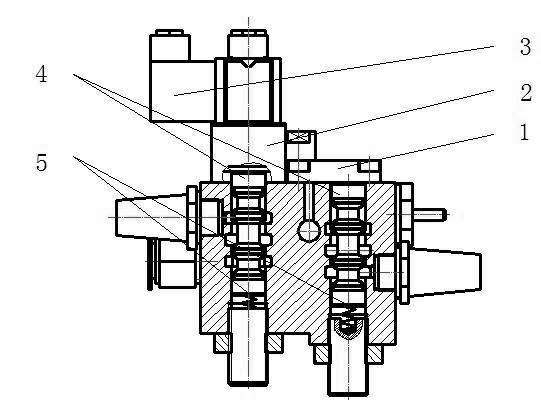

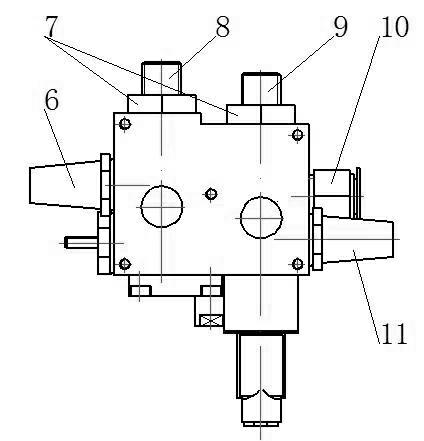

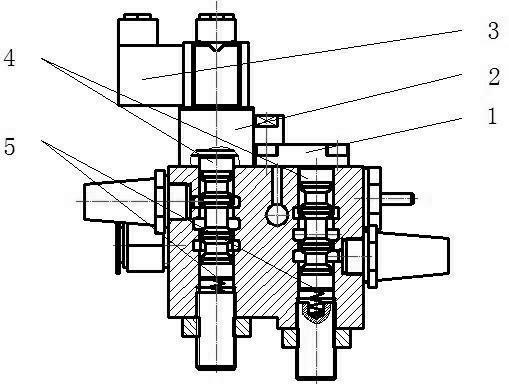

[0017] The high-efficiency, energy-saving and adjustable electrically-controlled electrolytic aluminum shell-breaking valve island system of the present invention is used in the electro-pneumatic circuit of electrolytic aluminum production equipment. Core, 5—spring, 6—valve 2 silencer, 7—lock nut, 8—valve 2 spring seat, 9—valve 1 spring seat, 10—total air source, 11—valve 1 silencer.

[0018] Installed on the cylinder head. The control method of the high-efficiency and energy-saving adjustable electric-controlled electrolytic aluminum shelling valve island system integrates the gas source inlet, an electromagnetic reversing valve (valve 1), an air-controlled reversing valve (valve 2) and a The speed throttle valve and the one-way valve to control the fast reverse; the air inlet is connected to the two outlets on the valve island through the passage of the electromagnetic reversing valve, the pneumatic control valve, and the throttle valve, and the two outlets on the valve isla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com