Inlet and outlet gas confluence device of eleven-high-pressure-gas-cylinder trailer

A technology of confluence device and high-pressure gas cylinder, which is applied in gas/liquid distribution and storage, pipeline system, container discharge method, etc. Novel structure, reducing air leakage, reducing installation stress and temperature difference stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

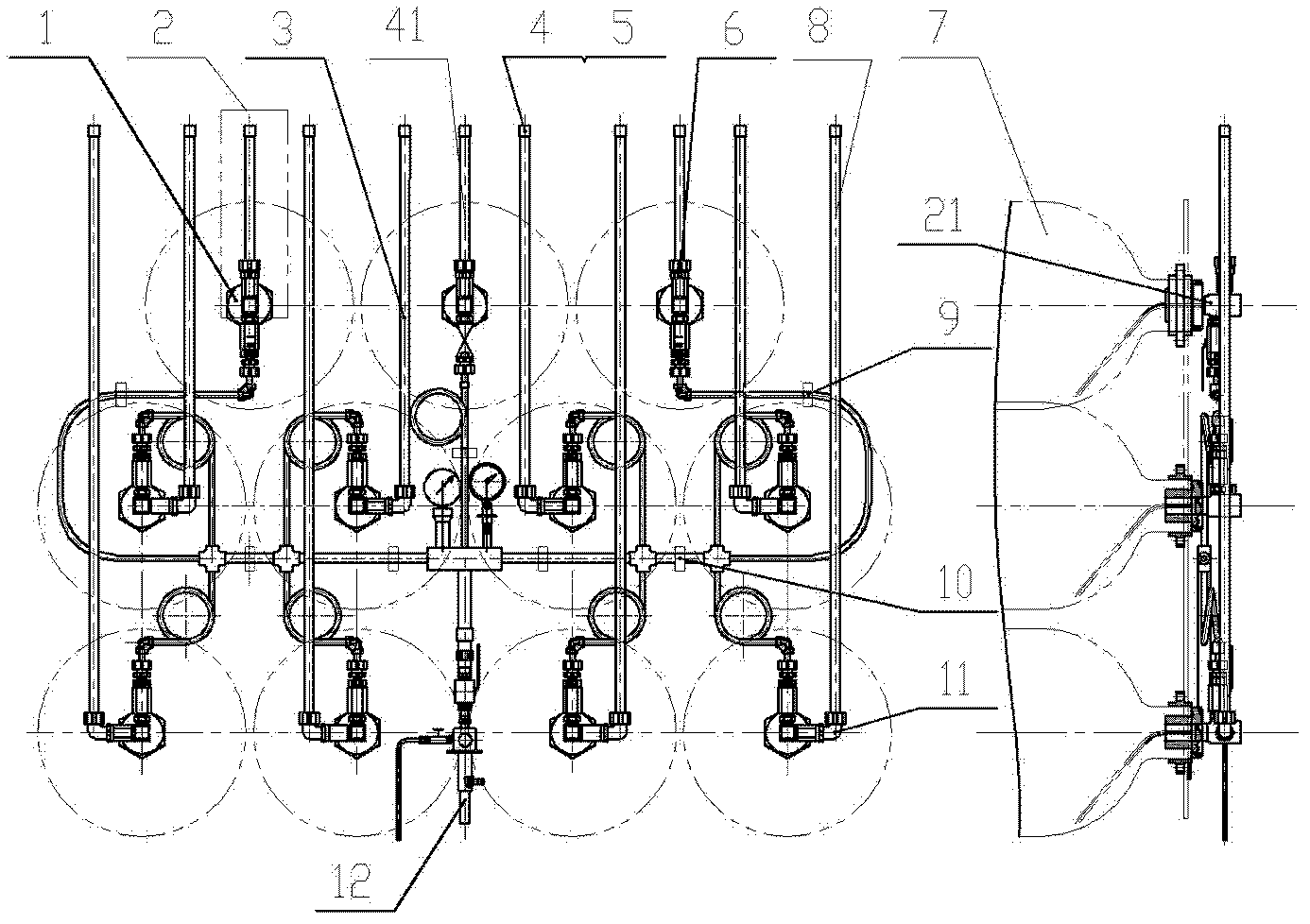

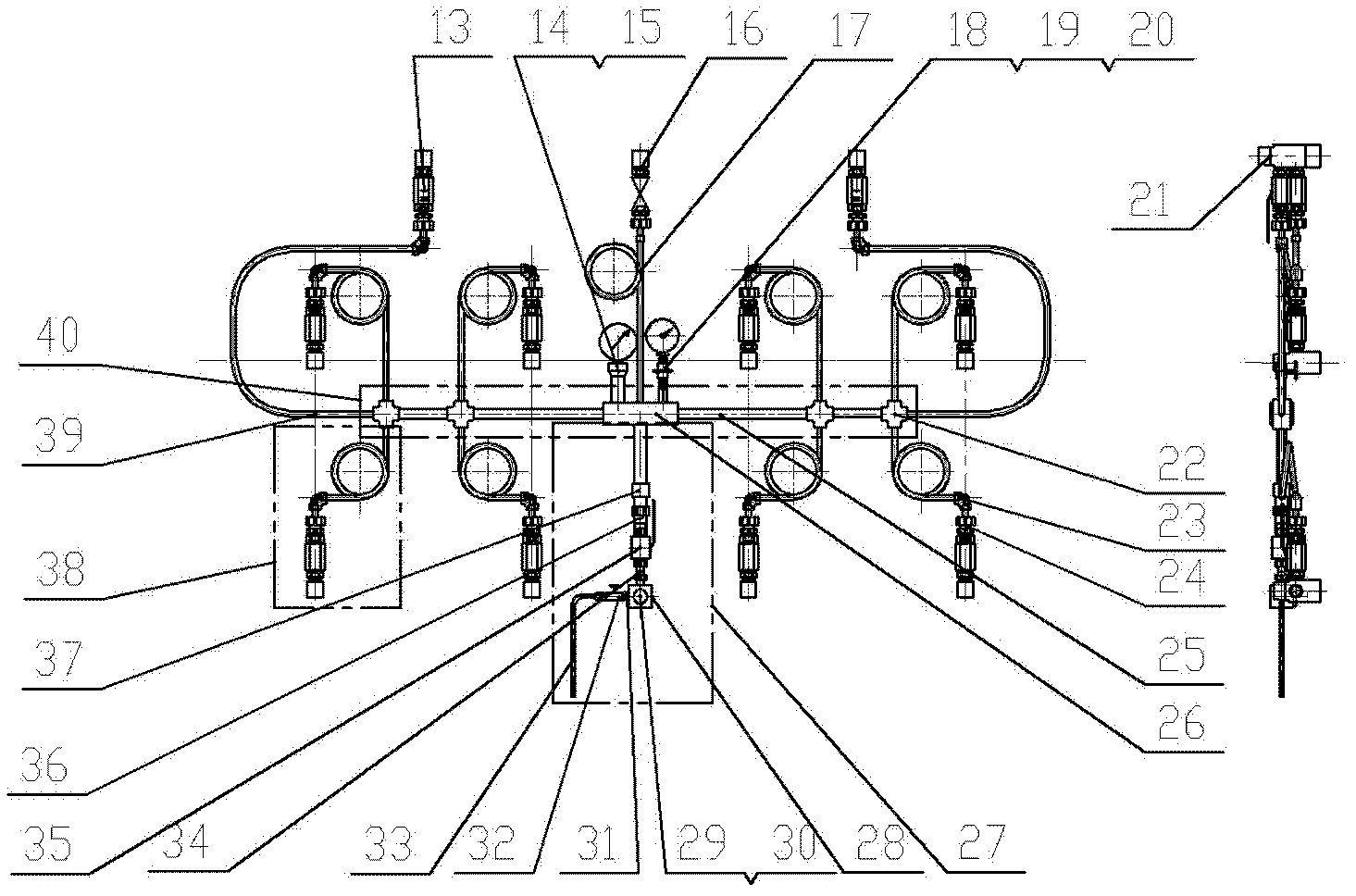

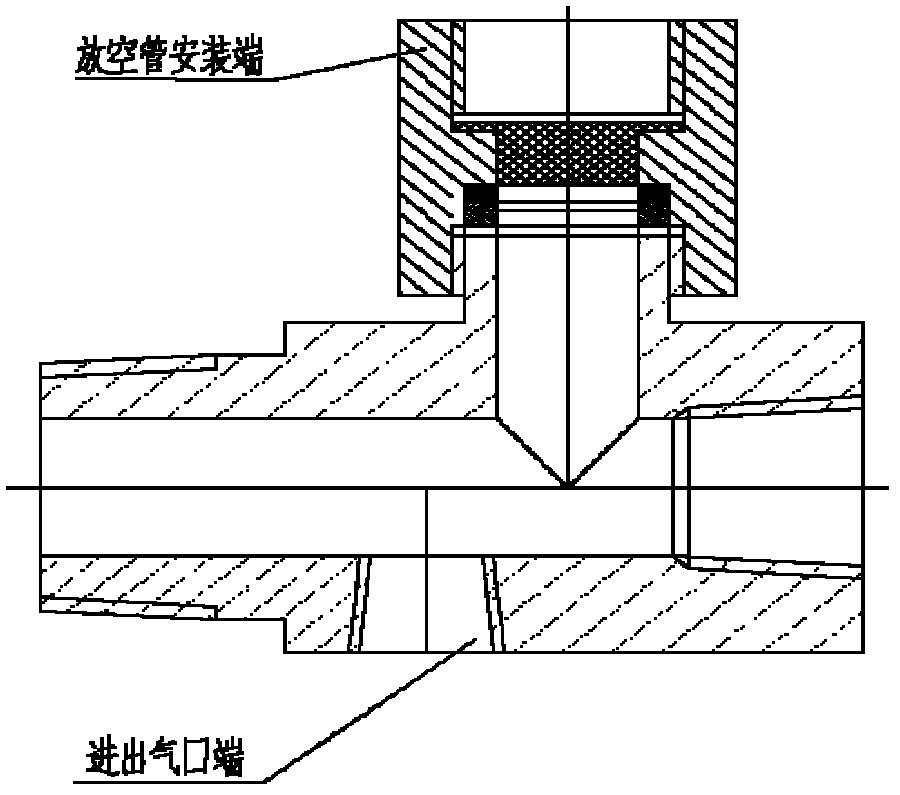

[0022] The present invention includes a main air inlet and outlet pipeline 27, a high-pressure six-way 26, a collective pipeline 40, a four-way joint 22, a communication pipeline 38, an NPT1 / 2″ pair of wires 16, a safety emptying device 2, and an end plug 1. Three-stage Fixed; the upper end of the main air inlet and outlet pipeline is connected to the output port of the lower end of the high-pressure six-way, the summary pipeline is connected to the output ports of the left and right ends of the high-pressure six-way, one end of the connecting pipeline is connected to the summary pipeline through a four-way joint, and the other end is Connect to end plug via NPT 1 / 2" pair of wire and safety drain. The three-stage fixing can be divided into primary fixing device, secondary fixing device and tertiary fixing device according to different fixing purposes. The main intake pipeline is fixed by the primary fixing device, the aggregate pipeline is fixed by the secondary fixing device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com