Detection method of metal nanometer film thickness

A metal nanometer and detection method technology, applied in the field of nanomaterials, can solve problems that affect the application, do not conform to the linear law, and the rate changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

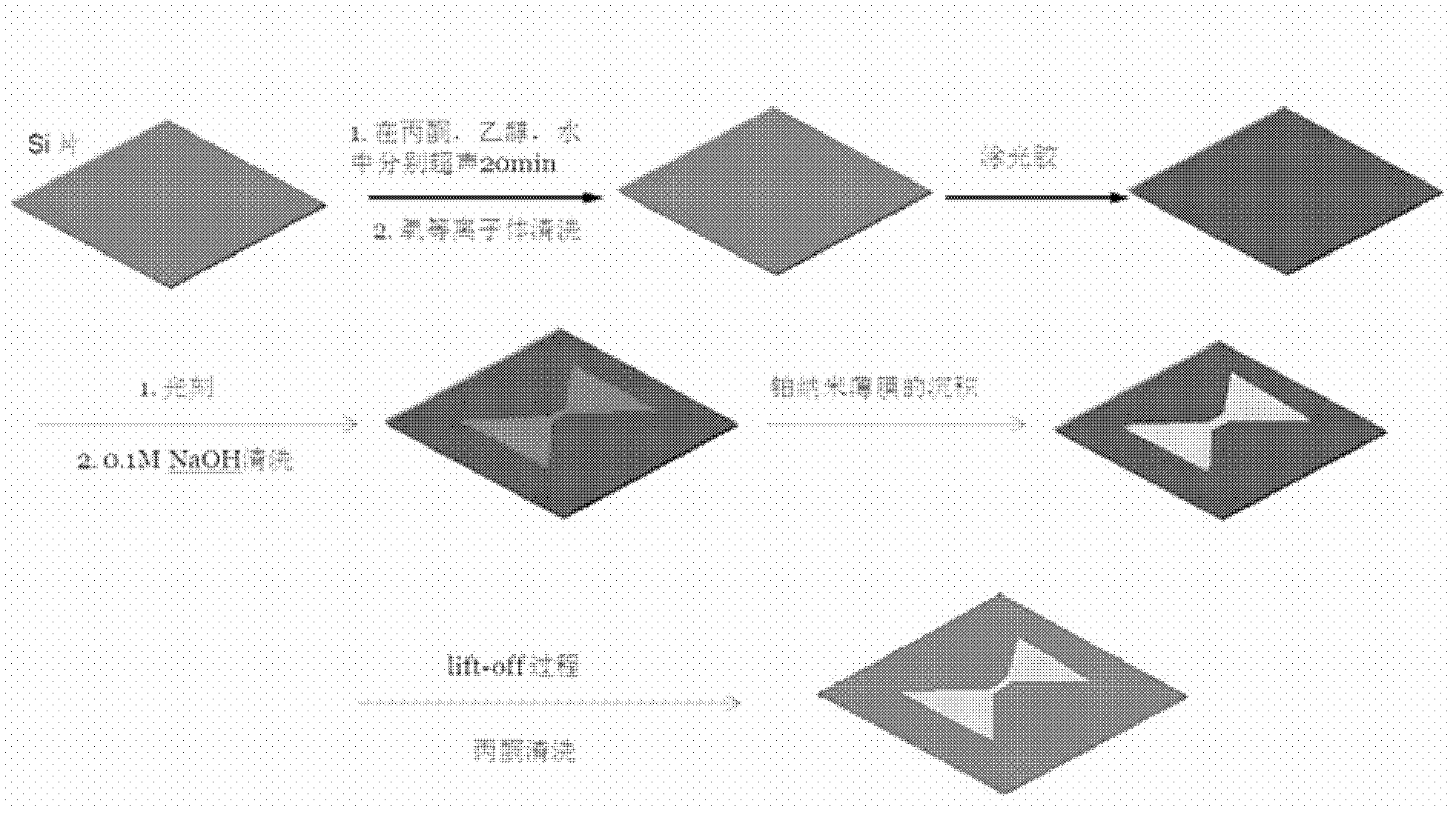

[0062] according to figure 1 The process flow shown prepares platinum nano-films with different thicknesses.

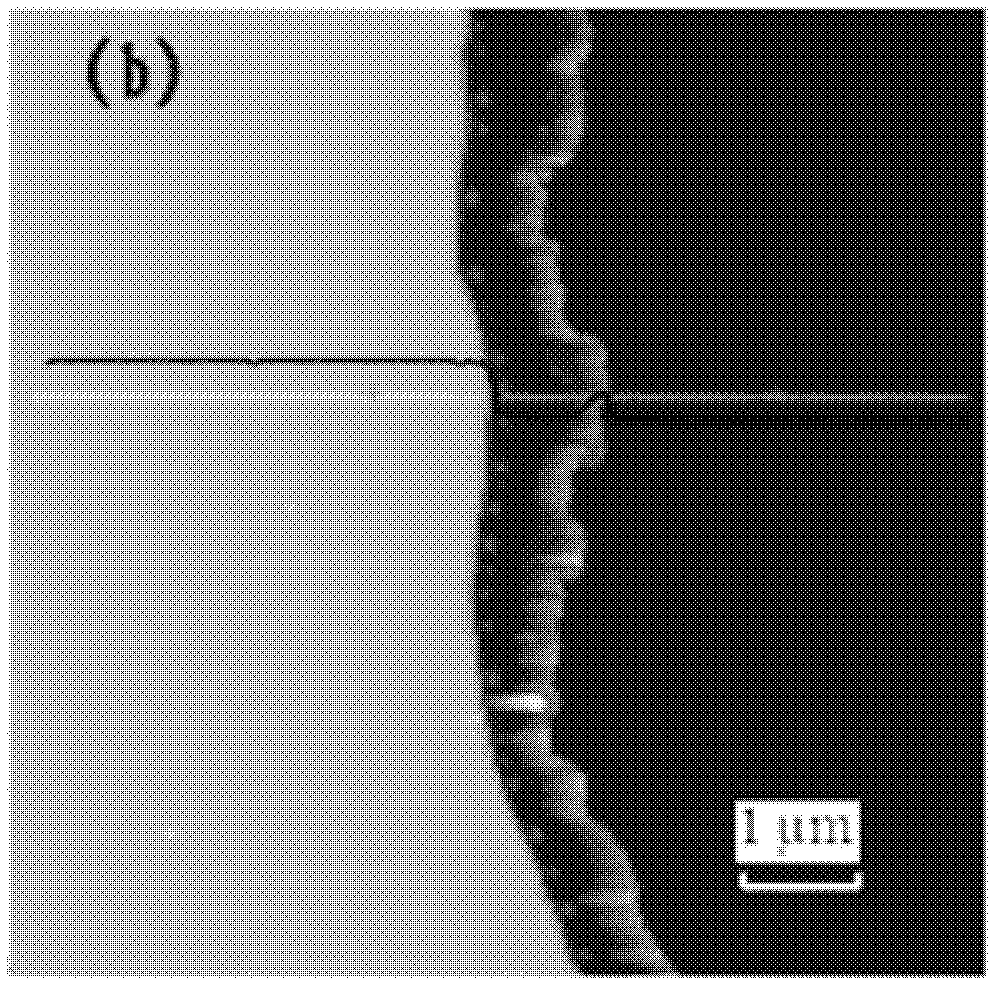

[0063] The obtained platinum nano-film is detected by an atomic force microscope in tapping mode, and the thickness of the platinum nano-film is obtained according to the obtained height map of the atomic force microscope.

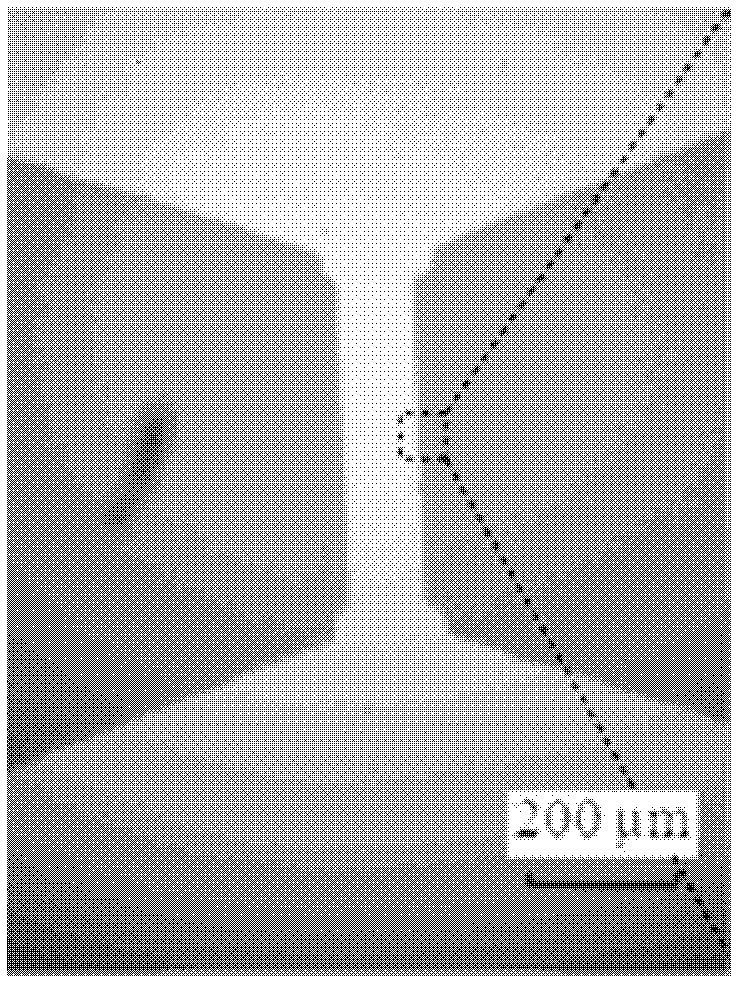

[0064] The result is as figure 2 and image 3 as shown, figure 2 For the optical micrograph of the platinum nanofilm prepared in Example 1 of the present invention, image 3 For the edge AFM height map of the platinum nanofilm prepared in Example 1 of the present invention, from image 3 The thickness of the platinum nanofilm can be obtained.

[0065] After obtaining the platinum nano-film, the present invention adopts the model to be the Hongda multimeter of DT 9204 to detect the resistance value of the platinum nano-film, according to the classical resistance law, obtain the relationship between the resistance value of the platinum nano-f...

Embodiment 2

[0068] The present invention selects the platinum nano-film prepared in embodiment 1, adopts the Hongda digital multimeter of DT 9204 to detect that the resistance value of the platinum nano-film is 29650 ohms, and calculates the platinum nano-film according to the standard curve obtained in embodiment 1. The thickness of nano film is 3.3nm; In order to verify the accuracy of method provided by the present invention, the present invention adopts atomic force probe microscope to detect the thickness of described platinum nano film with tapping mode, and the result is 3.2nm, the result is as shown in Table 1 Shown, table 1 is the detection result that embodiment 2~7 of the present invention obtains.

Embodiment 3

[0070] The present invention selects the platinum nano-film prepared in Example 1, adopts the Hongda digital multimeter of DT 9204 to detect and obtain the resistance value of the platinum nano-film to be 5520 ohms, and calculates the platinum nano-film according to the standard curve obtained in Example 1. The thickness of the nano film is 4.5nm; In order to verify the accuracy of the method provided by the present invention, the present invention uses an atomic force probe microscope to detect the thickness of the platinum nano film in a tapping mode, and the result is 4.6 nm, as shown in Table 1 Shown, table 1 is the detection result that embodiment 2~7 of the present invention obtains.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com