Method for detecting and regulating surface types of solar heat-collection condenser

A technology for solar heat collection and surface detection, which is applied in the directions of solar collectors, solar collector safety, solar thermal energy, etc., can solve the problem of measurement and adjustment technology, which is labor-intensive, consumes a lot of human resources and time, and detects and adjusts efficiency. It can improve the efficiency of detection and adjustment, the accuracy and reliability of error data, and facilitate quantitative adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

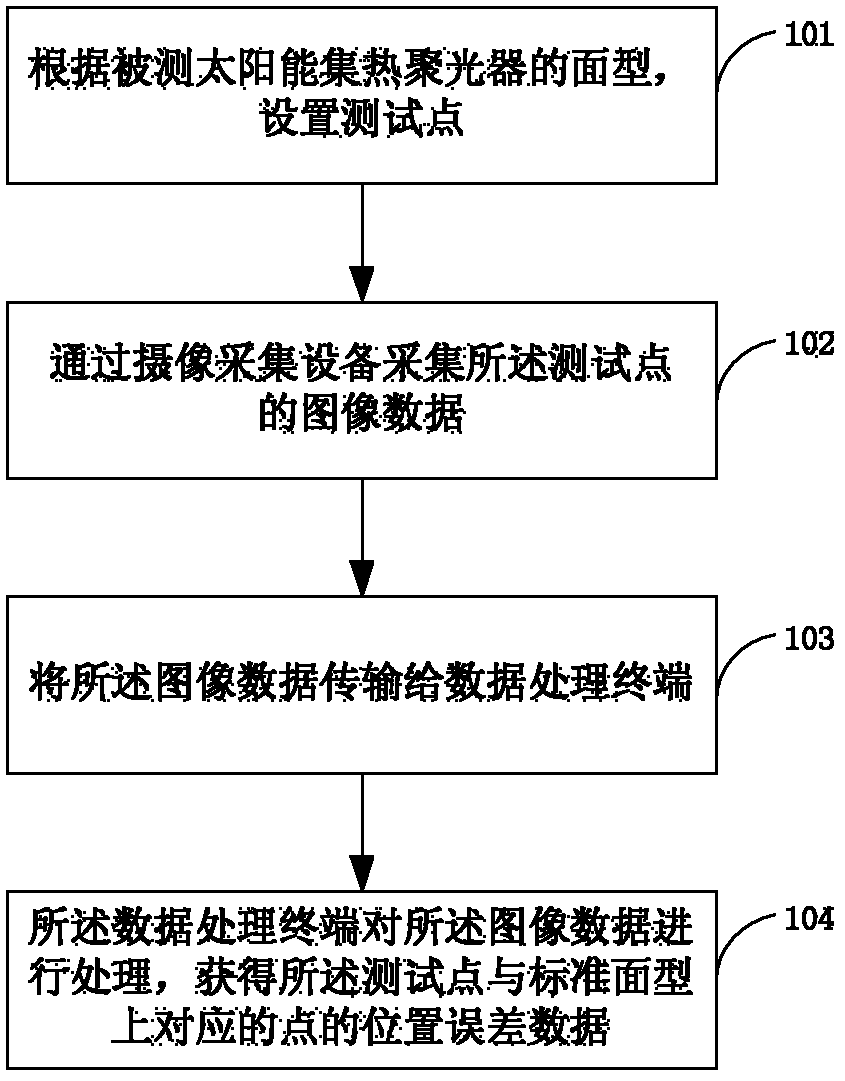

[0044] see figure 1 , an embodiment of the present invention provides a method for detecting the surface shape of a solar thermal concentrator, the method comprising:

[0045] Step 101: setting a test point 2 on the solar thermal concentrator 1 to be tested;

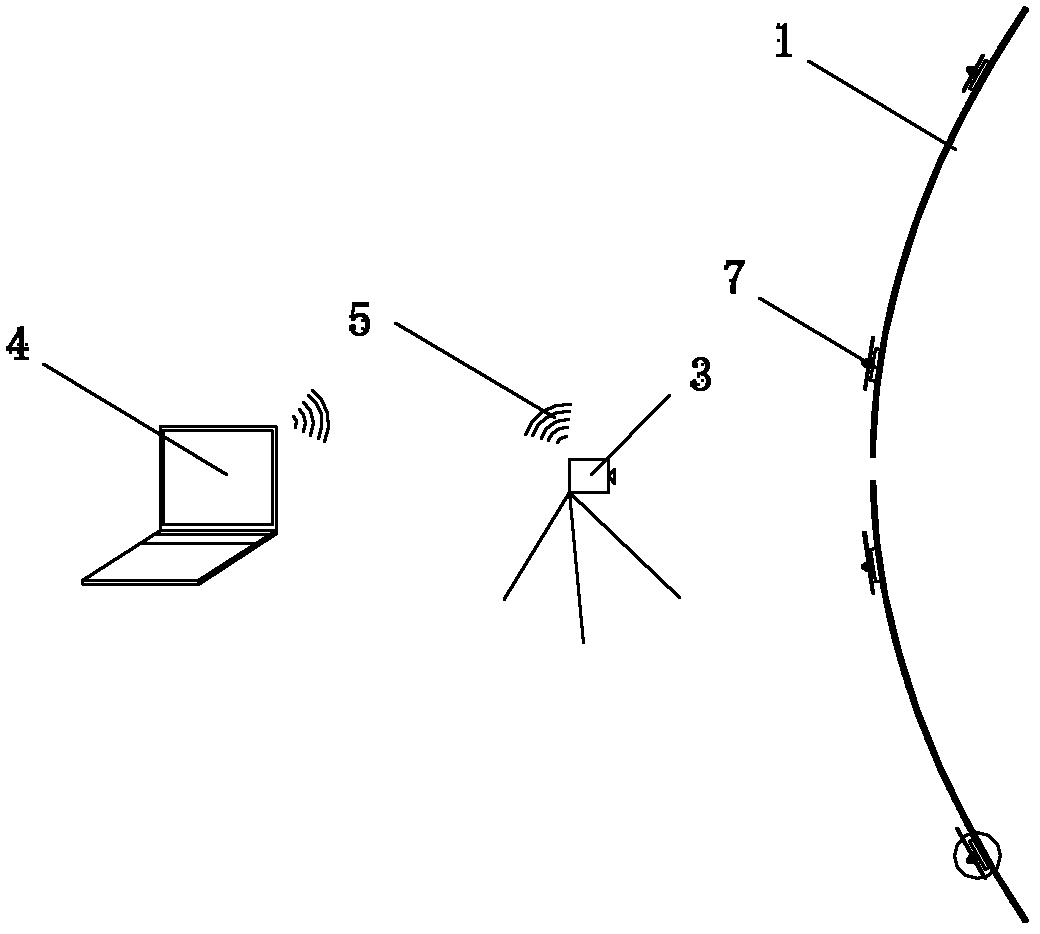

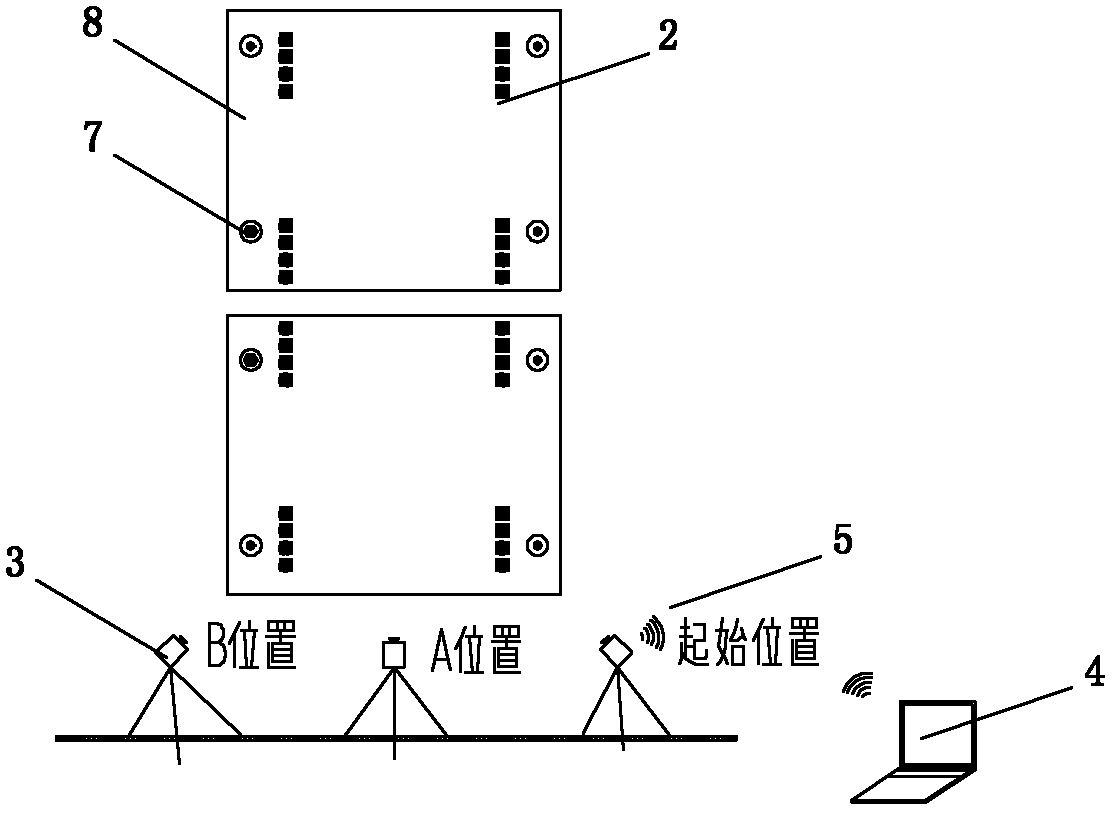

[0046] see figure 2 and image 3 The surface profile of the solar thermal concentrator 1 is composed of a plurality of reflectors 8 installed on the mirror adjustment mechanism 7, and the error between the surface profile of the solar thermal concentrator 1 and the standard profile is mainly due to the installation of the reflector 8. produce. see image 3 , select test point 2 on the reflector 8 of solar thermal concentrator 1, test point 2 is located around the mirror surface adjustment mechanism of reflector, the number of test point 2 can be selected arbitrarily according to needs, in the embodiment of the present invention, in order to be more To characterize the position of the reflector 8, four test points 2...

Embodiment 2

[0056] see Figure 4 , an embodiment of the present invention provides a method for adjusting the surface shape of a solar thermal concentrator, the adjustment method comprising:

[0057] Step 201: Detect the surface shape of the solar heat collector concentrator 1 by the surface shape detection method of the solar heat collector concentrator provided in Example 1, and obtain the position error data of the test point 2;

[0058] The detection method provided by Example 1 can accurately obtain position data such as the three-dimensional coordinates of all test points 2, the normal data of the surface where they are located, so that the normal of the test point 2 and its corresponding point on the standard surface can be accurately found The direction error data provides accurate theoretical basis and data support for adjusting the surface shape.

[0059] Step 202: Adjust the mirror adjustment mechanism 7 according to the position error data;

[0060] see Figure 5 , the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com