Double long period fiber grating (LPFG) temperature and humidity sensor

A temperature and humidity sensor, fiber grating technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve problems such as restricting the practical application of long-period fiber grating humidity sensors, and improve reliability and safety. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

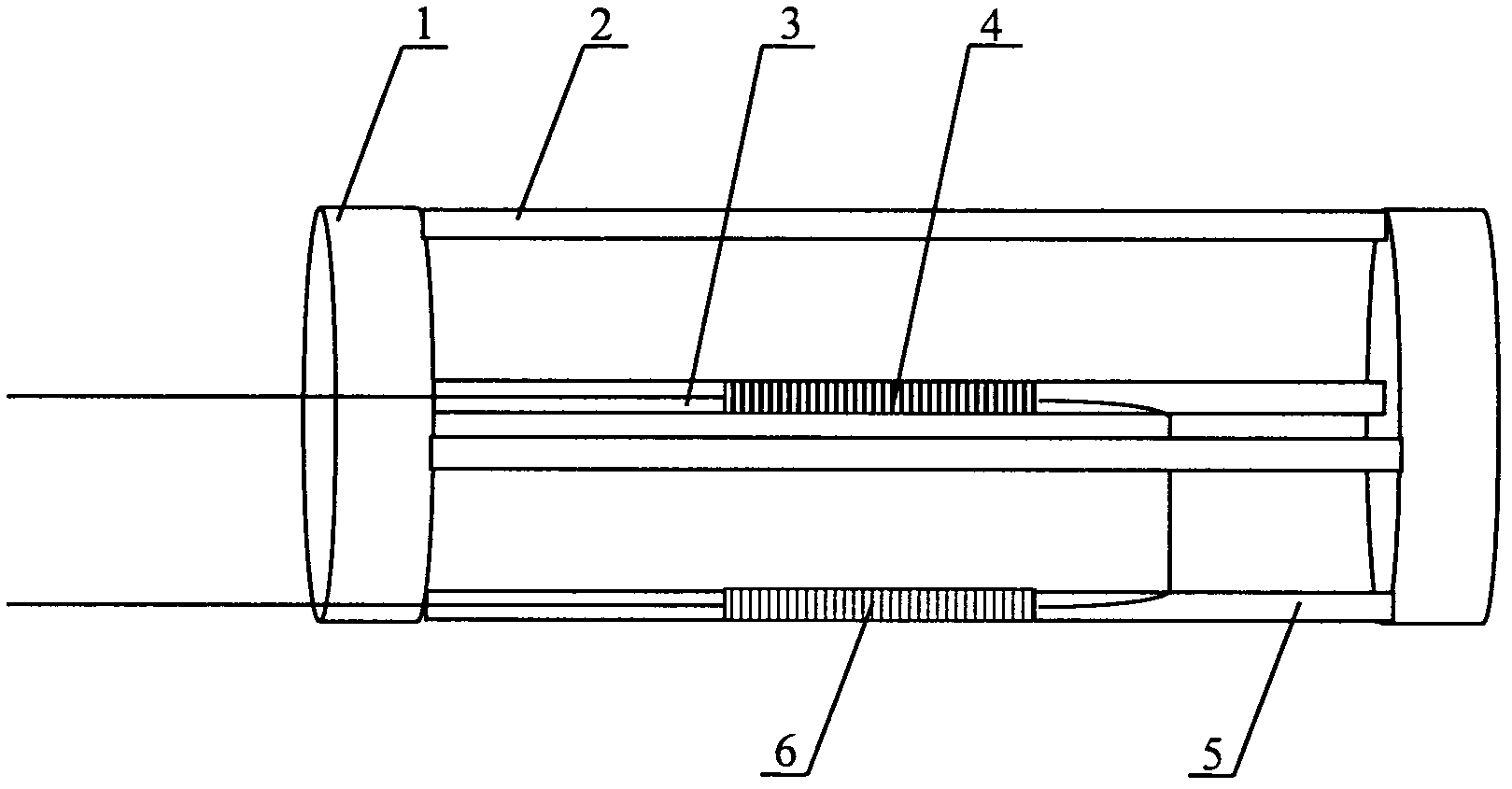

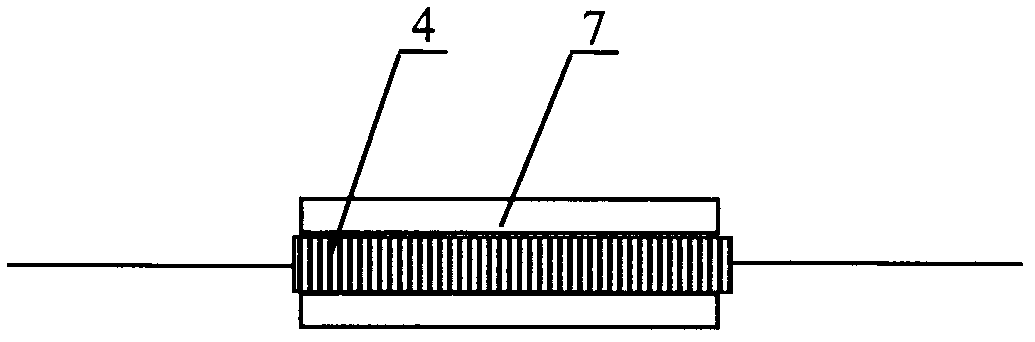

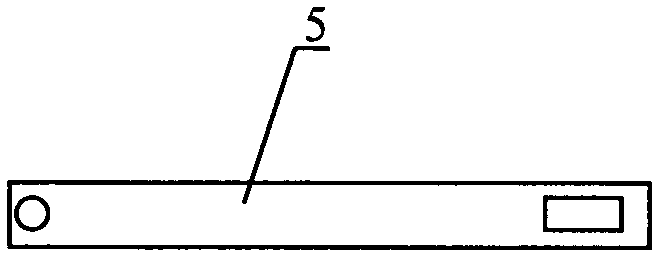

[0020] Depend on Figure 1~3 It can be seen that the double long-period fiber grating temperature and humidity sensor of the present invention is composed of a sensing body 1, a supporting straight beam 2, a metal sleeve 3, a moisture-sensitive long-period fiber grating 4, a temperature-sensitizing straight beam 5, and a temperature-sensitive long-period The optical fiber grating 6 and the humidity-sensitizing film 7 are connected to form.

[0021] Among them: there are two sensing bodies, both of which are made of stainless steel. There is one temperature-increasing straight beam 5 and three supporting straight beams 2 fixedly connected between the sensing bodies 1 with threaded fastening connectors, and two supporting straight beams 2, temperature-increasing straight beam 5 and supporting straight beams can also be installed on the connection. Beam 2 is symmetrical lamellar structure, and the width of temperature-increasing straight beam 5 and support straight beam 2 is 0.5...

Embodiment 2

[0029]In this embodiment, one temperature-sensitizing straight beam 5 and three supporting straight beams 2 are fixedly connected axially between the two sensing bodies 1 with threaded fastening connectors, and are evenly distributed on the periphery of the sensing body 1 In the axial direction, the width of each straight beam is 0.5cm, the length is 7cm, and the thickness is 0.5mm, in a strip structure. A temperature-sensitive long-period fiber grating 6 is bonded to the temperature-sensitizing straight beam 5 with 383 glue, and the wavelength of the temperature-sensitive long-period fiber grating 6 is 1535-1555 nm. The center of the sensor body 1 is processed with a center hole, and the metal sleeve 3 is penetrated into the center hole, and the two ends of the metal sleeve 3 are bonded in the center of the two sensor bodies 1 with 502 glue, and the humidity-sensitive type has a long cycle time. Both ends of the fiber grating 4 are bonded to the inner surface of the metal sle...

Embodiment 3

[0031] In this embodiment, one temperature-sensitizing straight beam 5 and three supporting straight beams 2 are fixedly connected axially between the two sensing bodies 1 with threaded fastening connectors, and are evenly distributed on the periphery of the sensing body 1 In the axial direction, each straight beam has a width of 0.5cm, a length of 7cm, and a thickness of 1mm, in a strip-like structure. A temperature-sensitive long-period fiber grating 6 is bonded to the temperature-sensitizing straight beam 5 with 383 glue, and the wavelength of the temperature-sensitive long-period fiber grating 6 is 1555nm? . The center of the sensor body 1 is processed with a center hole, and the metal sleeve 3 is penetrated into the center hole, and the two ends of the metal sleeve 3 are bonded in the center of the two sensor bodies 1 with 502 glue, and the humidity-sensitive long-period Both ends of the fiber grating 4 are bonded to the inner surface of the metal sleeve 3 with 383 glue....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com