Transformer oil gas detection device

A transformer oil and detection device technology, applied in the direction of sampling device, test sample preparation, etc., can solve the problems of low detection accuracy, limited diffusion area, sensor damage, etc., and achieve high detection accuracy, large penetration and diffusion area, and difficult damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

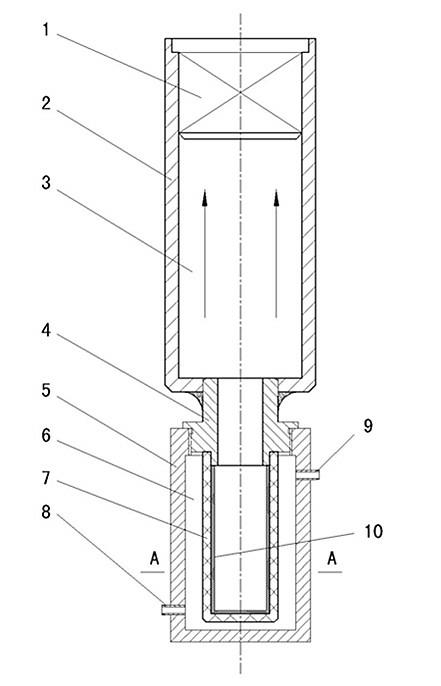

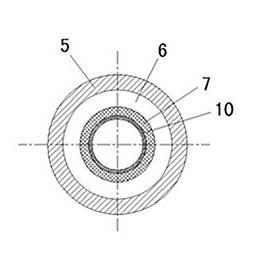

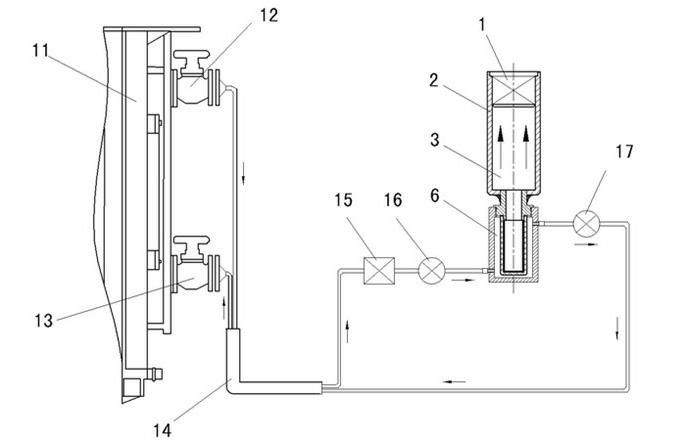

[0010] Such as figure 1 , 2 As shown: 2 is an upper casing, a gas sensor 1 is arranged on the inner side of the upper casing 2, and a gas chamber 3 is arranged below the gas sensor 1. A connecting sleeve 4 is welded below the upper casing 2 , and a lower casing 5 is threadedly connected below the connecting sleeve 4 . There is a transformer oil gas filter inside the lower housing 5 , and the transformer oil gas filter includes a metal particle cover 7 and a permeable membrane 10 attached to the inner surface of the metal particle cover 7 . The metal particle cover 7 is made of stainless steel particles by atomization method to produce spherical powder, and then sintered at high temperature in loose packaging. During the manufacturing process, the spherical powder is not affected by external force, and the sintering temperature is strictly controlled within a certain range. Keep the spherical shape, and form pores between the particles, and the porosity and the size between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com