Device for testing organic gas transmissivity

A test device, organic gas technology, applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems affecting the accuracy, repeatability and reproducibility of test data, poor pipeline sealing, In order to improve the convenience of testing, solve the problem of adsorption and condensation, and improve the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

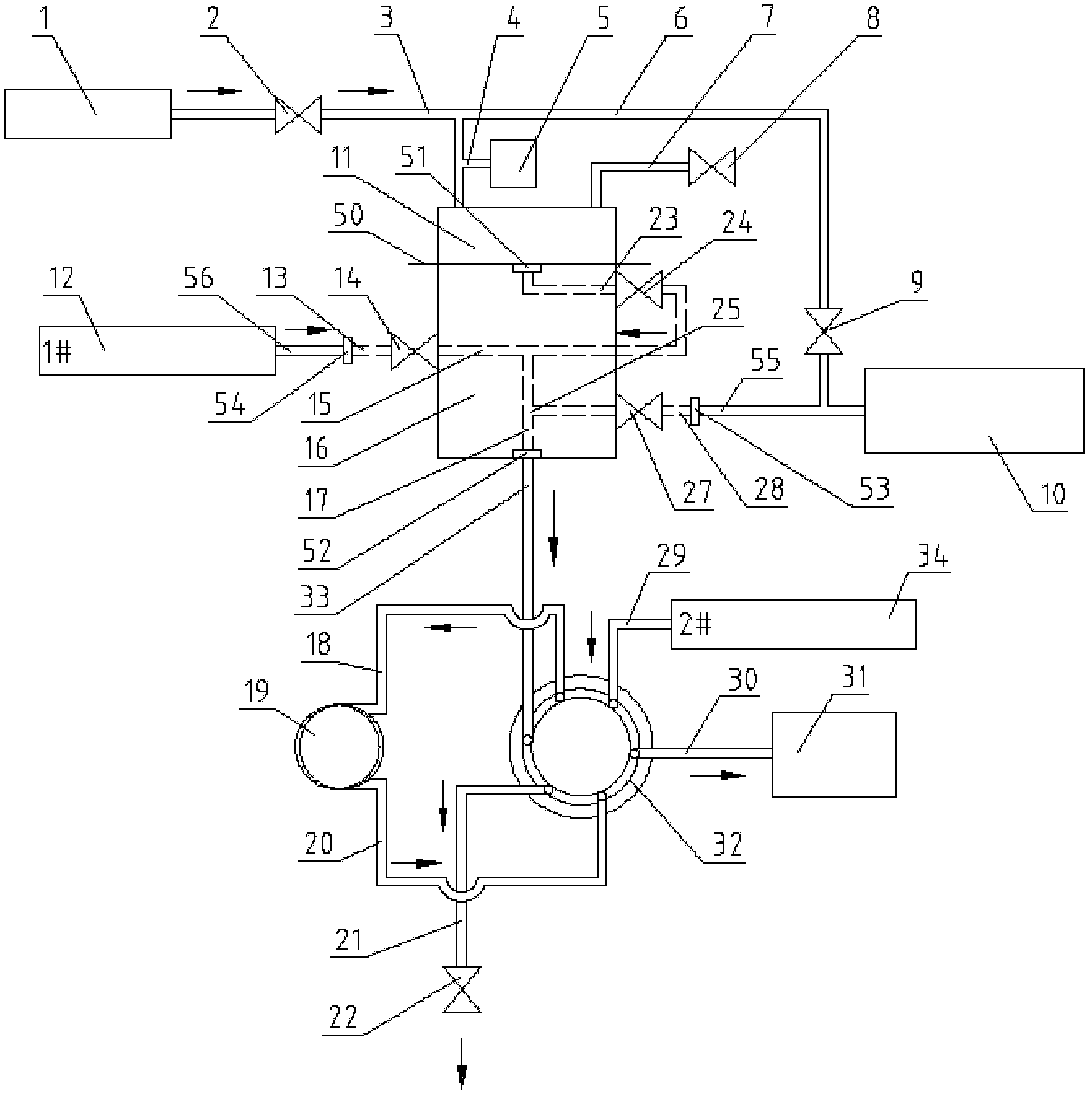

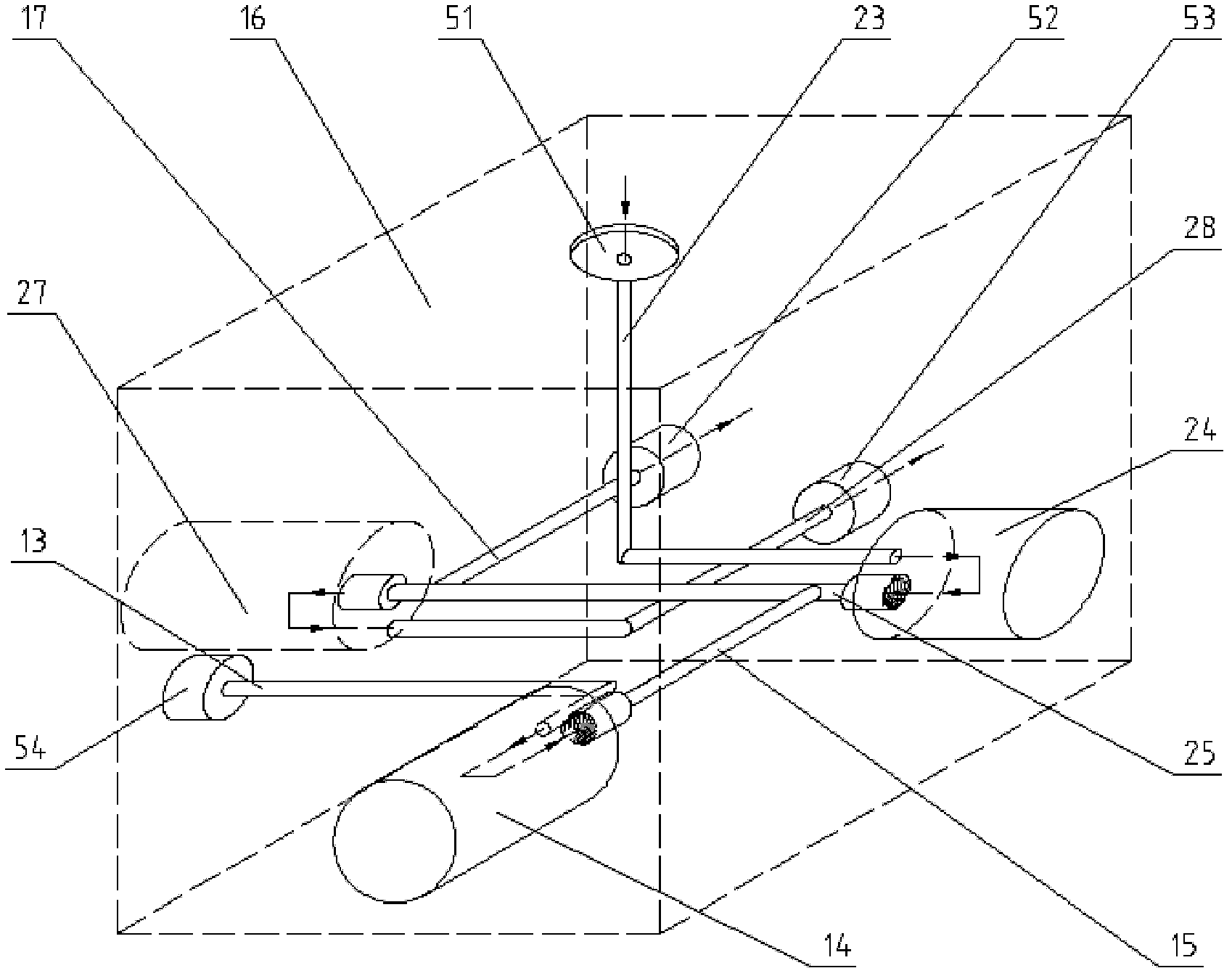

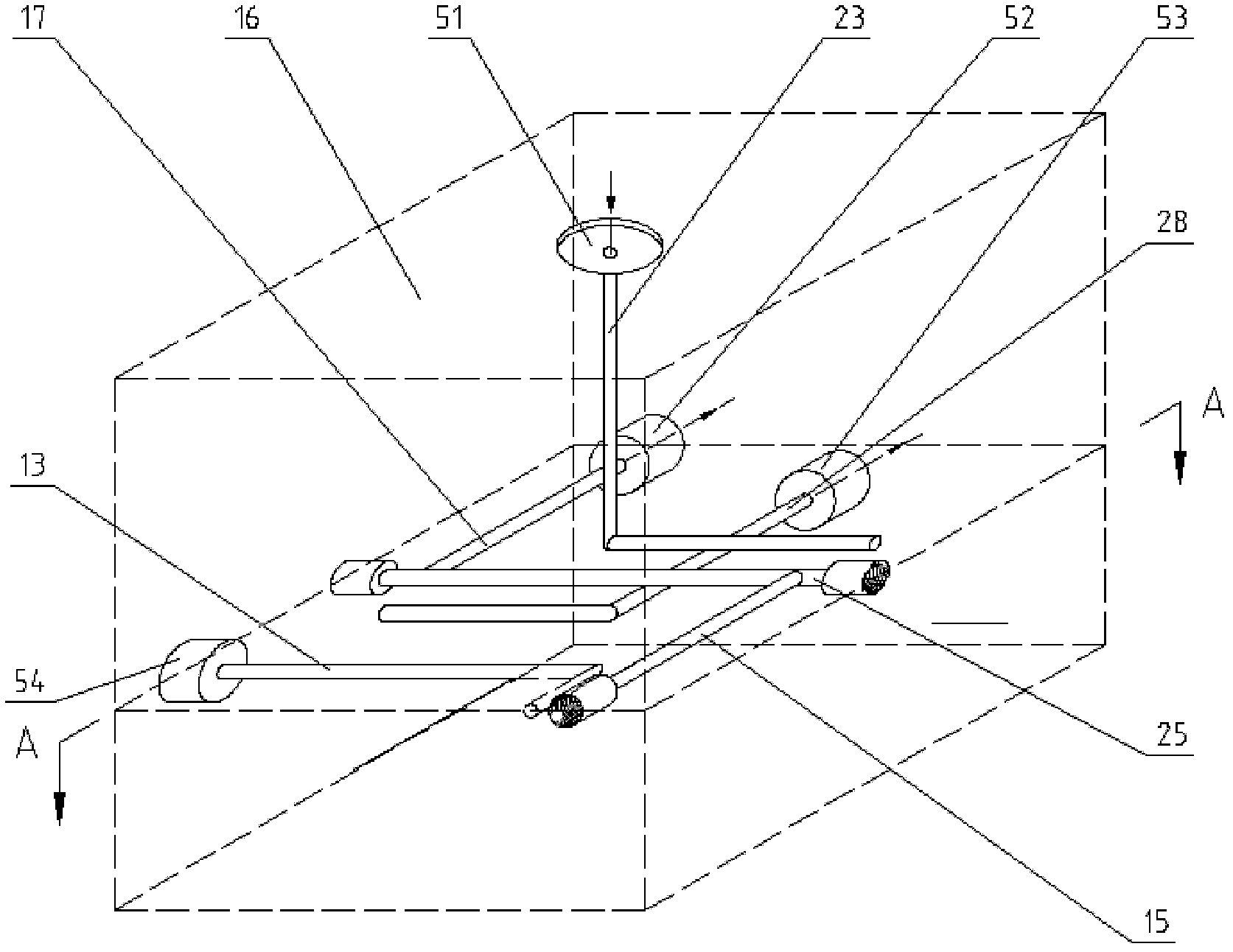

[0035] An organic gas transmission rate test device, combined with Figure 1-Figure 6 Among them, the present invention includes three parts: quantitative sampling device, permeation tank, and detection device 31, wherein the permeation tank is divided into two parts by sample 50, the upper cavity 11 of the permeation tank and the lower cavity of the permeation tank, and the lower cavity of the permeation tank includes three parts: a structural block 16, a valve, and a through hole. In the part, the permeation tank is connected with the detection device 31 through a quantitative sampling device. The structural block 16 is provided with a permeation air hole 51 , a sampling hole 52 , a vacuum pump air hole 53 and a carrier gas input hole 54 . Among them, the permeable air hole 51 is connected with the valve I24 through the through hole IV23; the vacuum pump air hole 53 is connected with the valve II27 through the through hole V28; the carrier gas input hole 54 is connected with...

Embodiment 2

[0038] An organic gas transmission rate test device, combined with Figure 2-4 , Figure 7-11 In this embodiment, the temperature of some structures in the quantitative sampling device is controlled to achieve a good test for gases with certain adhesion. Respectively connect the multi-station communication valve 32, the quantitative device 19, the pipeline II18 and the pipeline V20 connecting the multi-station communication valve 32 and the quantitative device 19, and the pipeline IV30 connecting the multi-station communication valve 32 and the detection device 31. The multi-station communication valve 32 and the pipeline VI21 of the valve IV22 carry out temperature control. At least one of the multi-station communication valve 32 and the quantitative device 19 has an independent temperature control device, and at least one of the pipeline II18, the pipeline IV30, the pipeline V20, and the pipeline VI21 is provided with a pipeline temperature control device. device. Whe...

Embodiment 3

[0040] An organic gas transmission rate test device, combined with Figure 2-4 , Figure 7-11 , in this embodiment, the multi-station communication valve temperature control device 66, the quantitative device temperature control device 65, and each pipeline temperature control device can adopt liquid temperature control devices, air temperature control devices, metal heating tubes, metal heating wires and Various methods such as heat-insulating materials and heat-insulating devices are used to realize it. For other contents, refer to Embodiment 2, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com